ARTgroup has been involved in electronics cooling using microfluidics jet for over two decades. Our team is dedicated to developing cutting-edge cooling technologies for electronic devices that meet the challenges of smaller, faster, and more powerful devices. We have emerged with many innovative system designs to cope with the increased thermal density of electronics in both air and dielectric liquids. Our research focuses on the use of jet impingement cooling utilizing a high-velocity jet of fluid to remove heat from surfaces.

Our group is currently working on several innovative jet impingement cooling technologies designed to address the cooling demands of future electronic devices, particularly those with high heat fluxes such as power transistors and microprocessors.

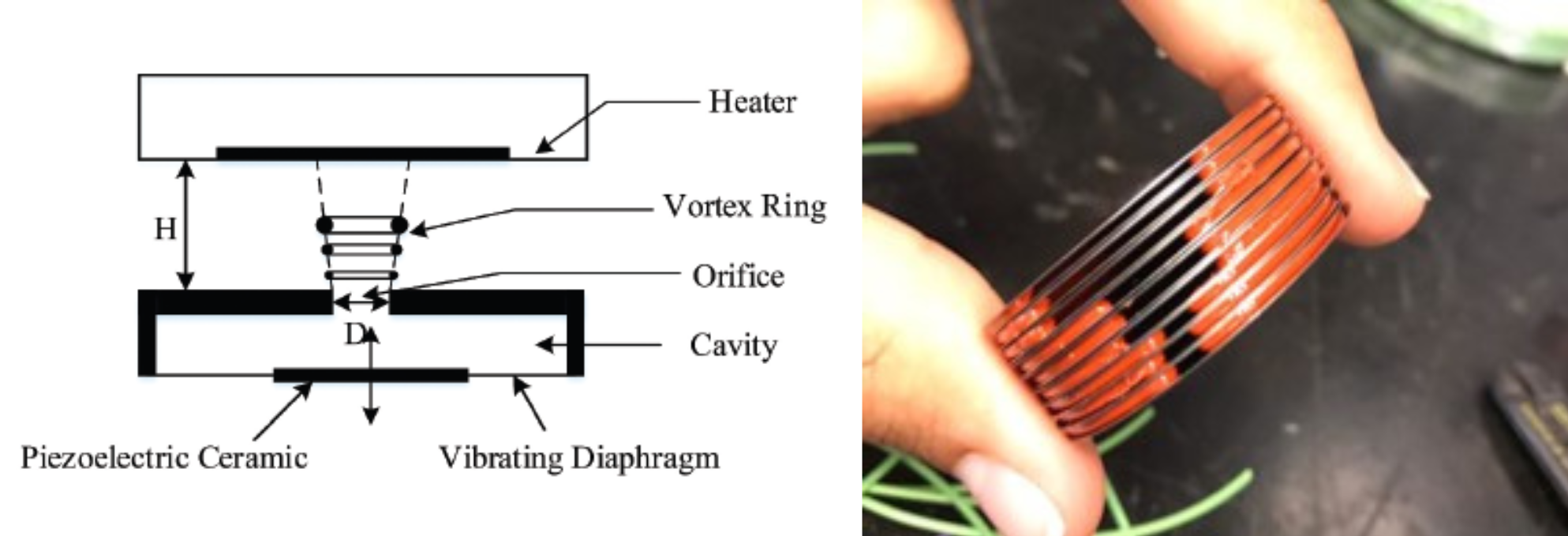

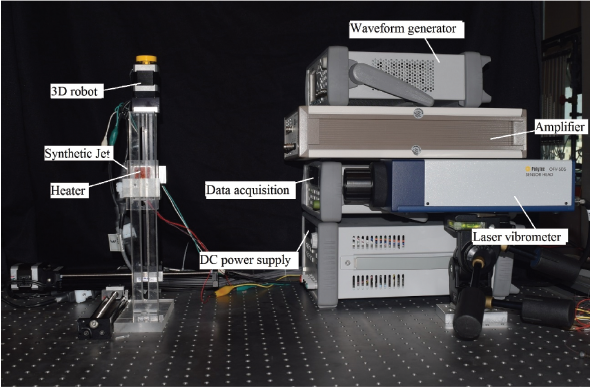

Among many exciting technologies, we are developing, synthetic jets (SJ) and microchannel embedded jets are two standout examples. Synthetic jets are created by utilizing a piezoelectric actuator generating a train of jets that promote efficient heat transfer. Microchannel embedded jets, on the other hand, utilize tiny channels in the impingement surface to enhance heat removal.

One of the key advantages of synthetic jet cooling is its ability to operate without any mechanical components that can wear out over time, such as pumps or fans. This means that the technology is extremely reliable and can operate for long periods of time without requiring maintenance. Synthetic jet stands out among other available cooling technologies because of its potential for miniaturization and energy efficiency, versatility to combine with other cooling methods to create hybrid systems, flexibility to operate with a wide range of fluids, and ability to provide localized cooling.

We explore the effects of different characteristic parameters of SJ such as; orifice size and type, orifice-to-plate spacing, Reynolds number, and stroke length etc.. Our team is dedicated to developing efficient jet designs for optimum heat enhancement with the lowest power consumption. By leveraging these new and innovative technologies, we are committed to developing cooling solutions that can handle even the most demanding applications.

Selected research articles:

- Acoustics and heat transfer characteristics of piezoelectric driven central orifice synthetic jet actuators

- Synthetic Jet Cooling Technology for Electronics Thermal Management—A Critical Review

- Flow and Heat Transfer Characteristics of Piezoelectric-Driven Synthetic Jet Actuator with Respect to Their Stroke Length