One of the research areas of ARTgroup is thermal management of lighting technologies especially light emitting diodes (LEDs). In our group, we work on coming up with innovative ideas and extending them for the proper thermal management of photonic systems. In this regard, we apply both experimental and simulation approaches to understand different thermal phenomena as well as to predict temperature. Our goal is to improve the existing thermal management and increase the efficiency of the systems.

Thermal and optical characterization: Immersion liquid cooled photonics devices

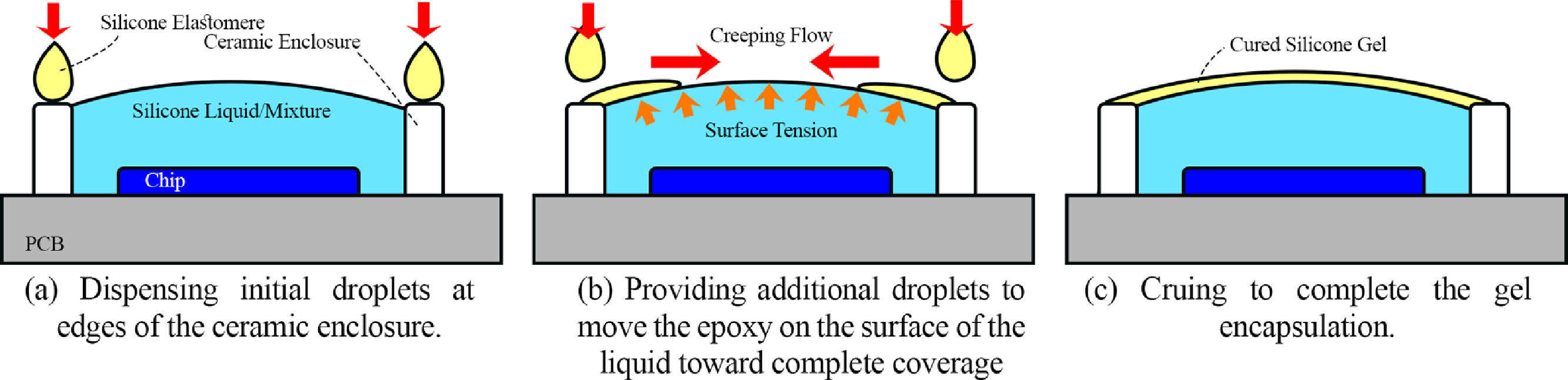

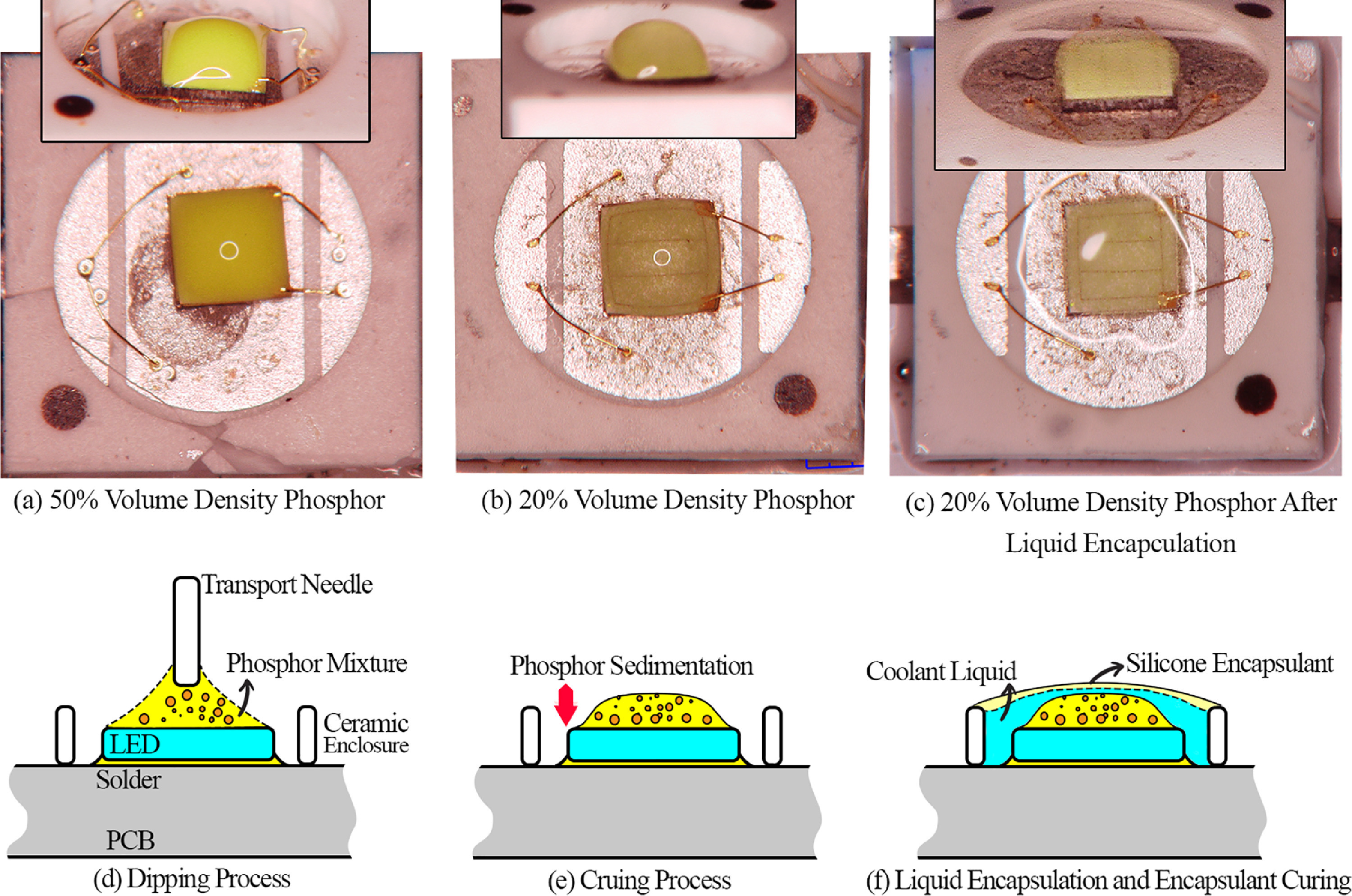

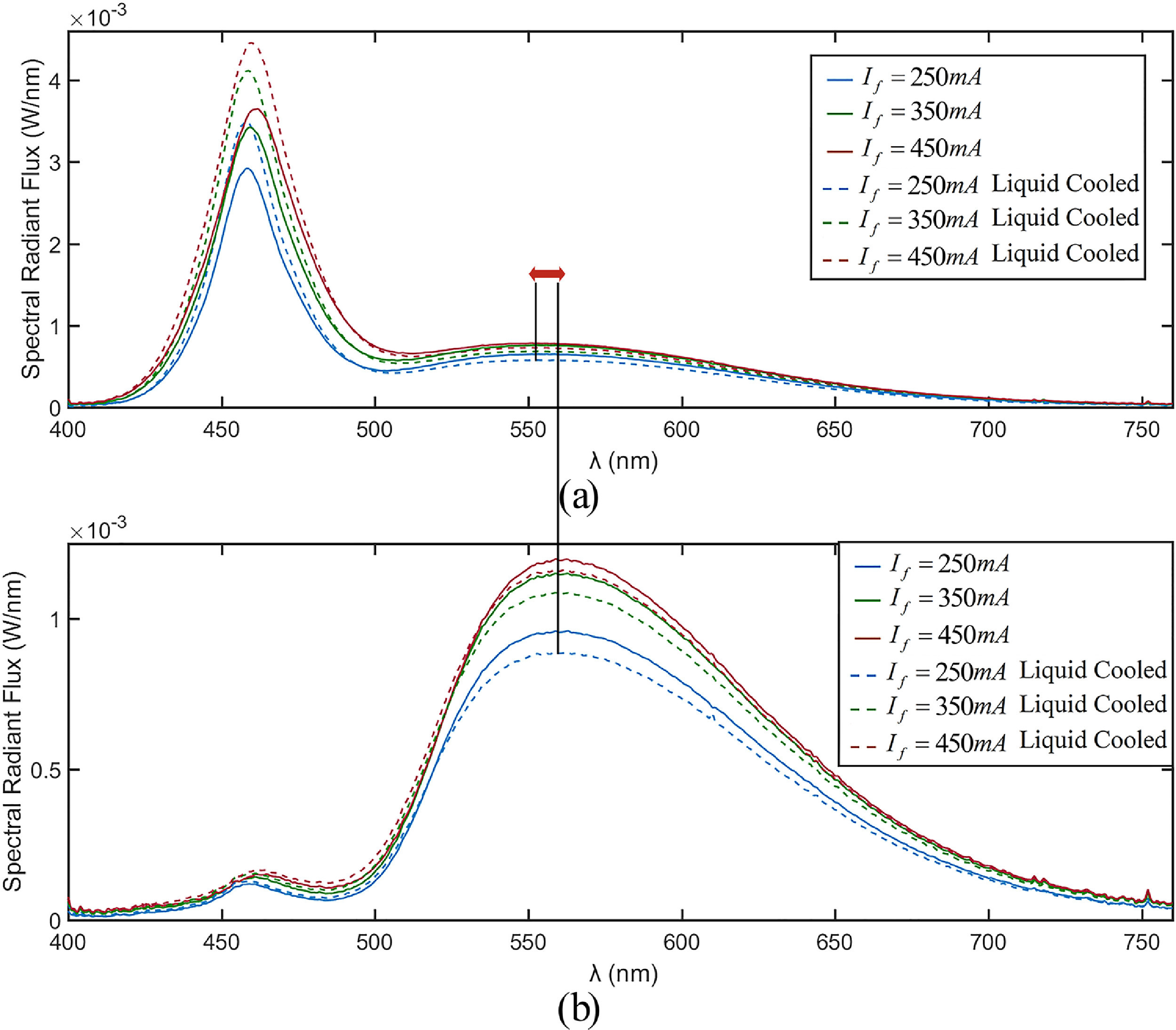

A direct passive liquid cooling technique has been investigated on bare and dip coated phosphor converted LEDs. While the previous approaches were focused on improving thermal passage toward the PCB or heat sink, this study introduces liquid cooling technique that directly targets heat generation regions and significant optical and thermal performance enhancements are observed. Direct liquid cooling decreases the temperature of the phosphor coating and prevents thermal quenching of phosphor. In this technique, a 30-fold increase in heat removal from LED exterior surfaces is achieved compared to conventional air cooling. While the ability of this technique is mainly governed by the thermal conductivity of the coolant, this encapsulation technique can be used in high power electronics packaging in different size scales.

Non-contact temperature measurement of photonics devices: EVAtherm system

ARTgroup has been working on the non-contact temperature measurement techniques over the last decade. Our lab has developed and demosntrated a patented approach which is more accurate than many other commerically available devices.

Patented EVAtherm system for junction temperature measurement of photonic devices

Selected research articles:

- Effect of Phase Change Materials on the Optical Path of LEDs for Opto-Thermal Enhancement

- High Brightness Illumination Based on Laser Light Diffusion With Mie Scattering

- Discrete Phase Analysis of Self Heating Particles Over an Immersion Liquid Cooled High Power Blue Light-Emitting Diode With Suspended Phosphor Particles

- Thermal and optical performance characterization of bare and phosphor converted LEDs through package level immersion cooling