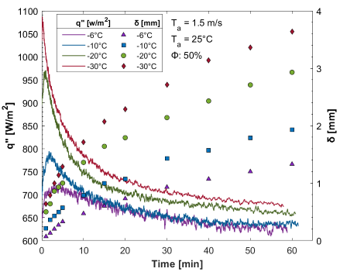

Frost formation is a major problem in a number of practical applications, such as refrigerators, Air-Conditioners, suction lines of compressors, Unmanned Aerial Vehicles (UAVs), and airplanes. Frost formation is the accumulation of frost on cooled surfaces that generates a thermal barrier between the surface and air. This leads a surface to lose its ability to heat transfer with the surrounding medium. A test systemhaving a controlled environment has been built in our laboratory. Our group has interest in understanding effect of heat flux and surface properties over dynamic frost thickness both experimentally and theoretically.

Frost formation on flat surface models via commercial CFD codes has been achieved. The frost growth was numerically modeled with Eulerian – Eulerian Multiphase modeling approach.

Frost formation on flat surface models via commercial CFD codes has been achieved. The frost growth was numerically modeled with Eulerian – Eulerian Multiphase modeling approach.

Selected research articles: