Removing excessive heat during system operations has been one of the major challenges in engineering, especially in areas where high heat fluxes are dissipated such as power plants and electronic systems. Concerning latter devices, working speed, and technical functionality have increased remarkably over the last few decades, while the systems are further required to occupy small spaces. Nucleate pool boiling heat transfer (BHT) is a potential heat removal mechanism to extract excess heat generated from compact components. This passive heat removal method uses the remarkable advantage of latent heat of vaporization and presents a high efficiency without pump-induced fluid transport. In our group, the objective is to enhance the boiling heat transfer with mechanical surface treatment methods such as microdrill machining to control the artificial nucleation sites, additive manufacturing to reach out eccentric mechanical microstructures, and laser texturing process to reduce the production time of the necessary micro structuring and to understand fundamentals of Critical Heat Flux (CHF) in dielectric fluids.

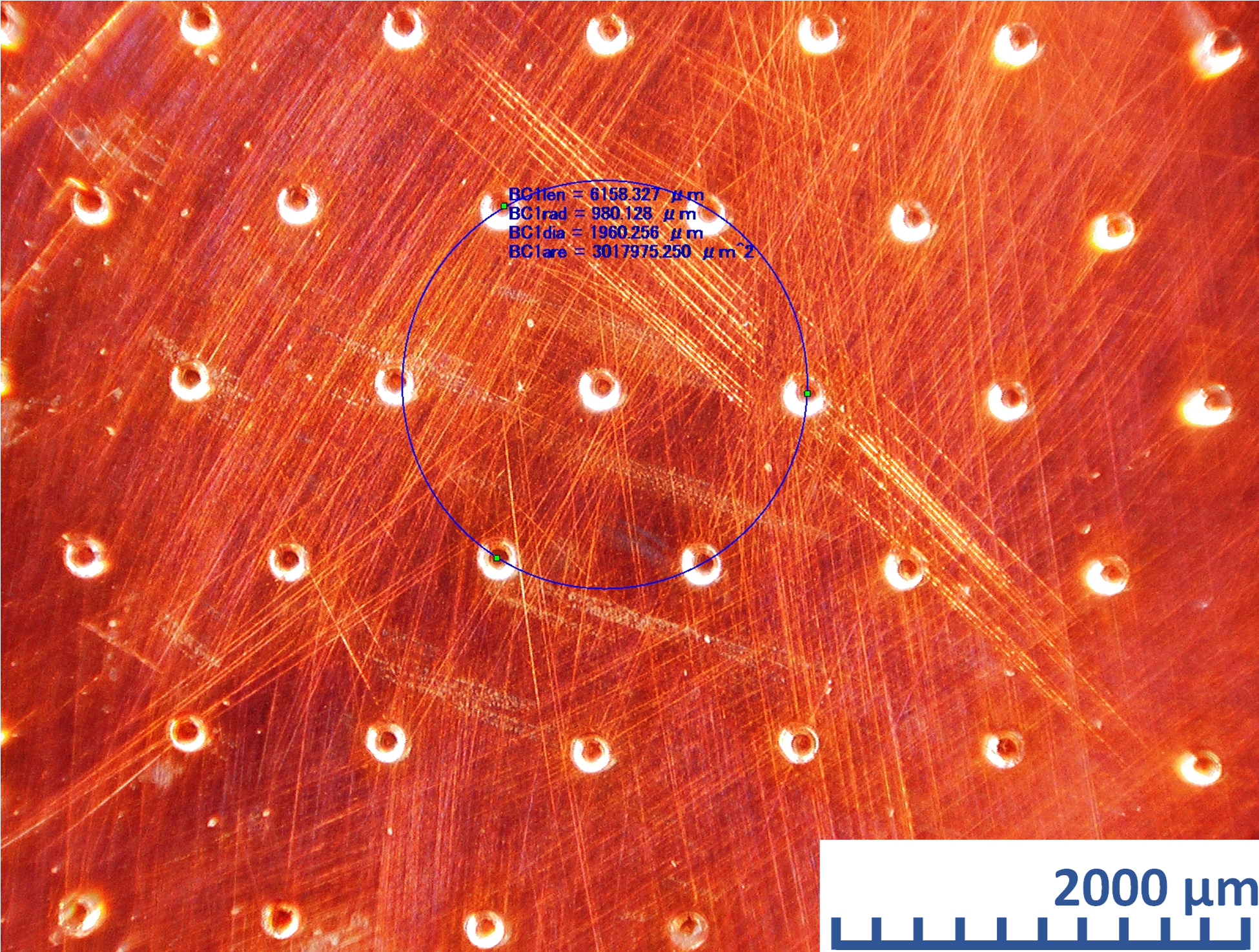

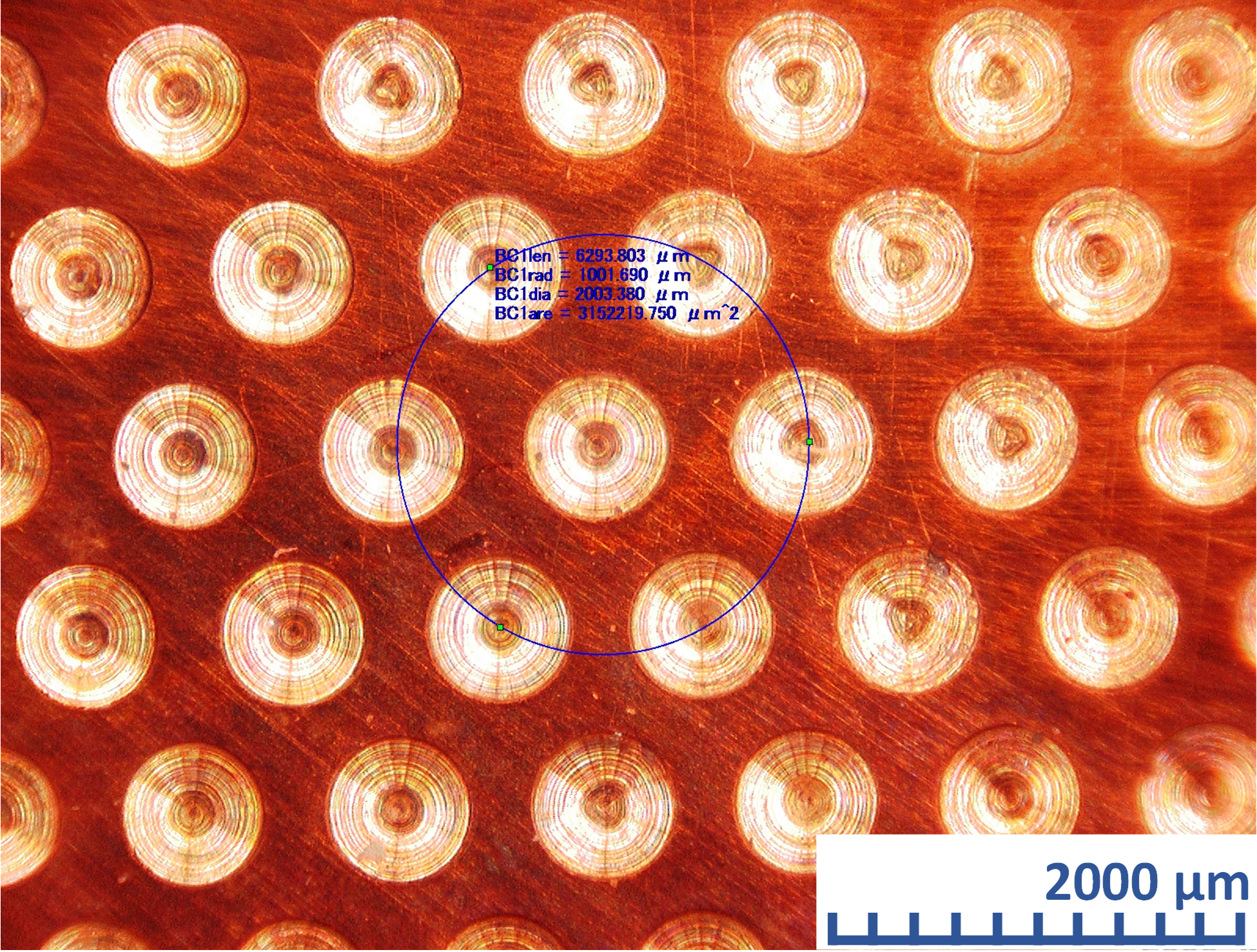

Microscopic images of the copper surfaces micro-drilled with a diameter of 200 µm and 1000 µm respectively

Geometrical dimensions, section view, and confocal analyses of the additive manufactured surfaces: a-d-g) MC1, b-f-g) MC2, and c-f-i) MC3 microchannel surfaces. The scale bars on section views refer to 500 µm

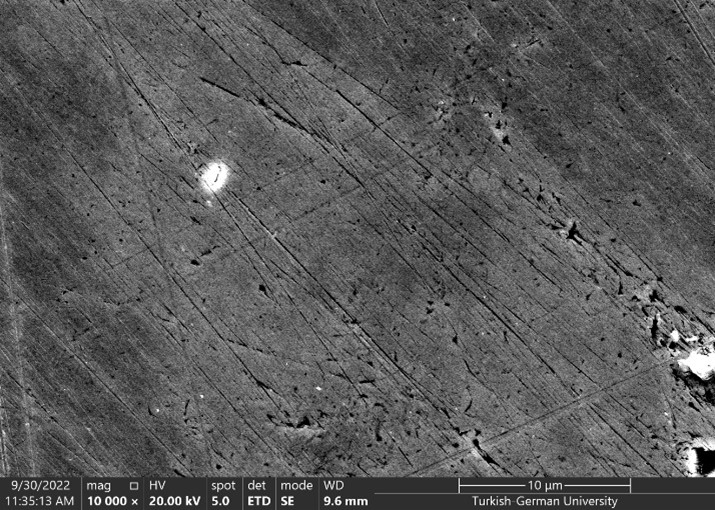

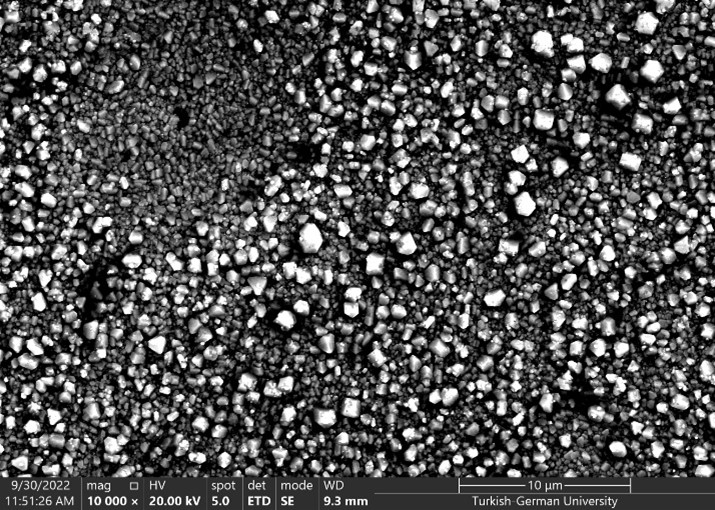

In addition, a chemical reaction of oxidation on metallic heating surfaces exposed to the evaporation process is an inevitable phenomenon. X-ray diffraction (XRD) analyses and scanning electron microscope (SEM) are utilized to determine the oxide compounds in nano scales as shown below.

SEM images of the bare surface (left) and the surface exposed to boiling crises and continuous boiling operations(right)

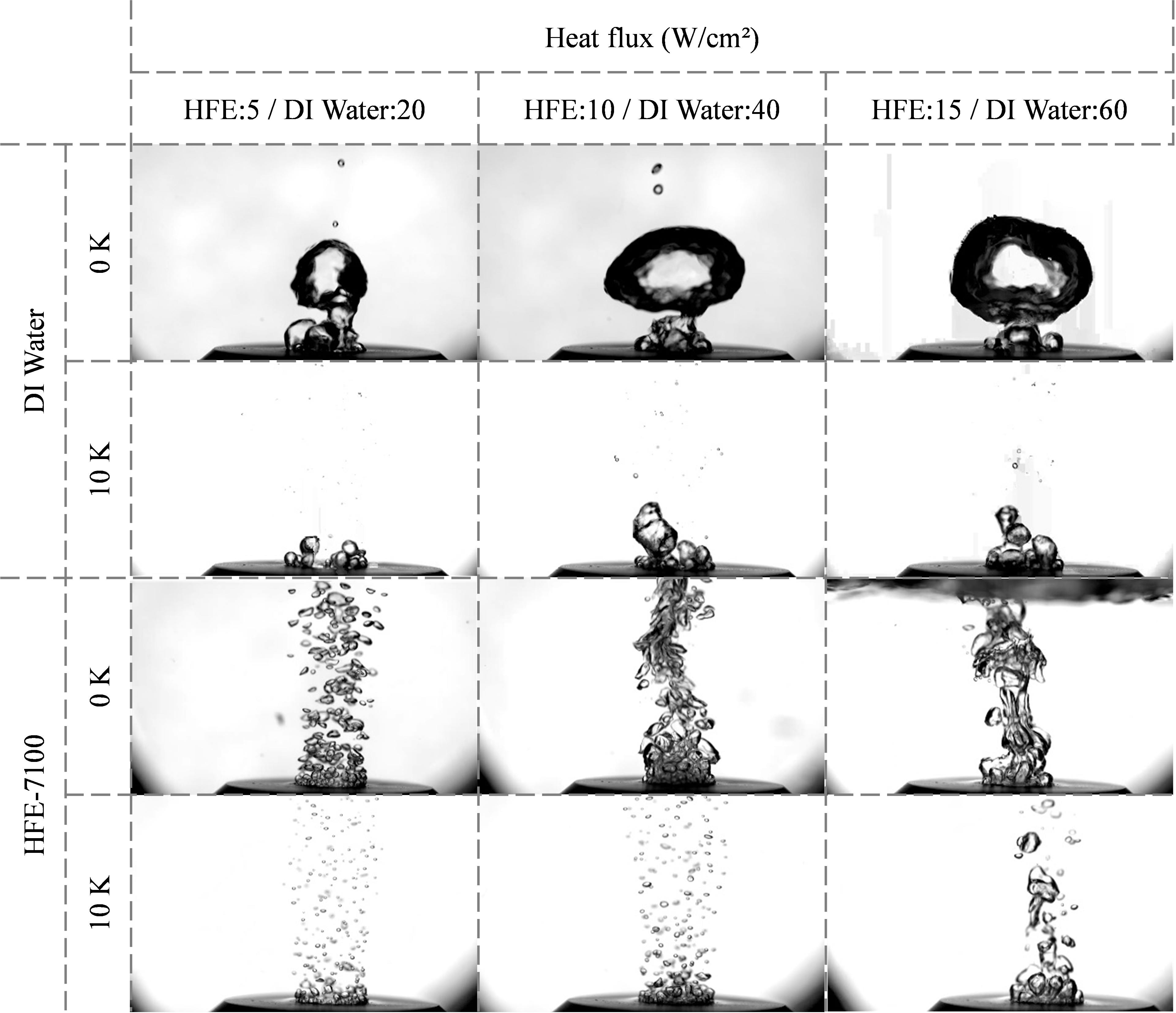

A sample wetting characteristics and bubble formations on fresh and exposed surfaces are associated with the surface topography by utilizing confocal microscopy, optical tensiometer, and high-speed imaging technique is given below.

Bubble formation in DI water and HFE-7100

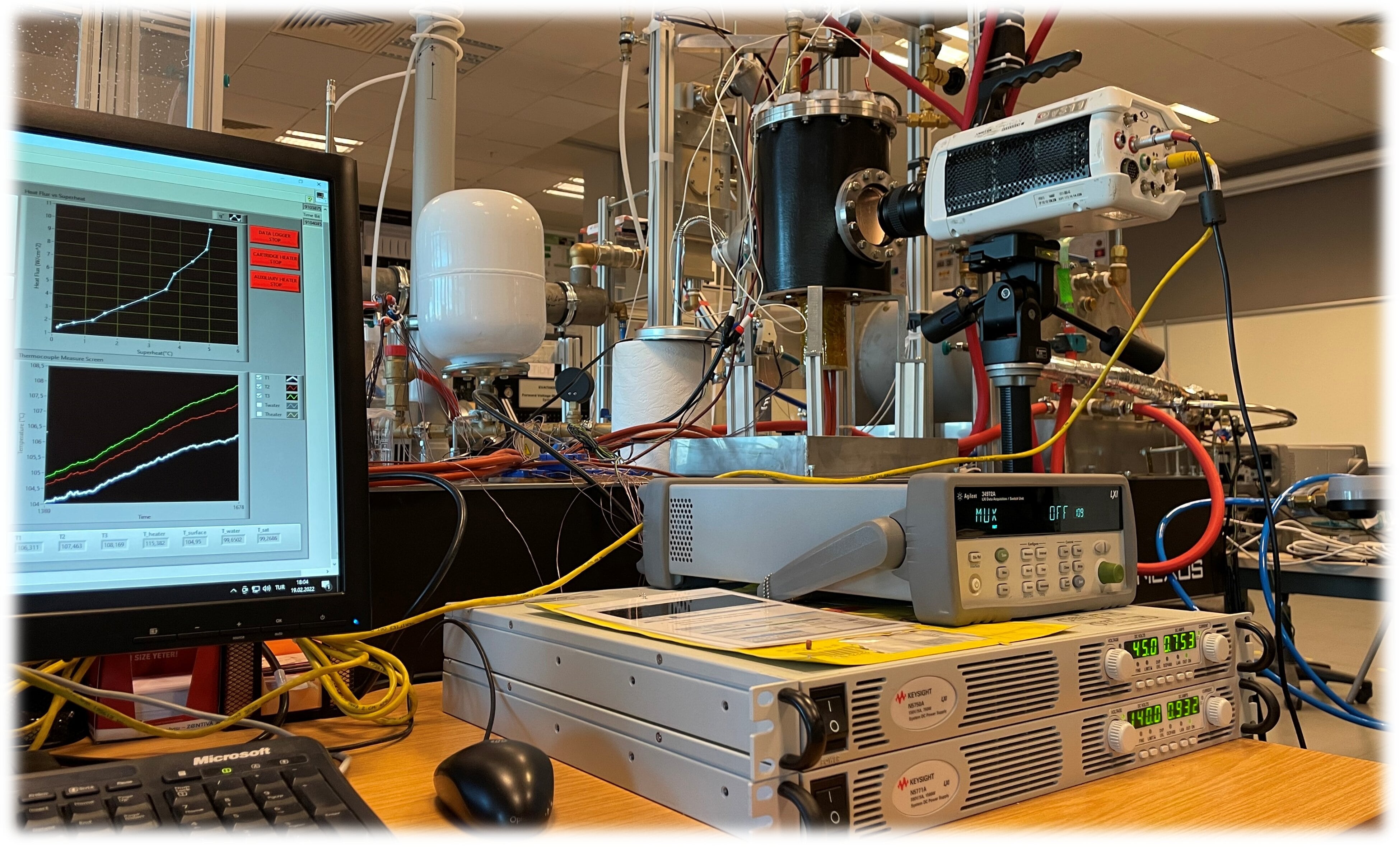

Boiling experimental system

Selected research articles: