Condensation heat transfer has a great significance for various industrial applications such as vapor-liquid heat exchangers, heat pipes, distillation columns, defrost processes, and thermal management systems. This complex phenomenon occurs when the vapor hits a surface having temperatures lower than the saturation temperature of the gas phase or when the operating temperature increases at a constant subcooling temperature. Film-wise condensation(FWC) and Drop-wise condensation(DWC) are two types of condensation, which occur depending on the rate of wettability between wall and liquid.

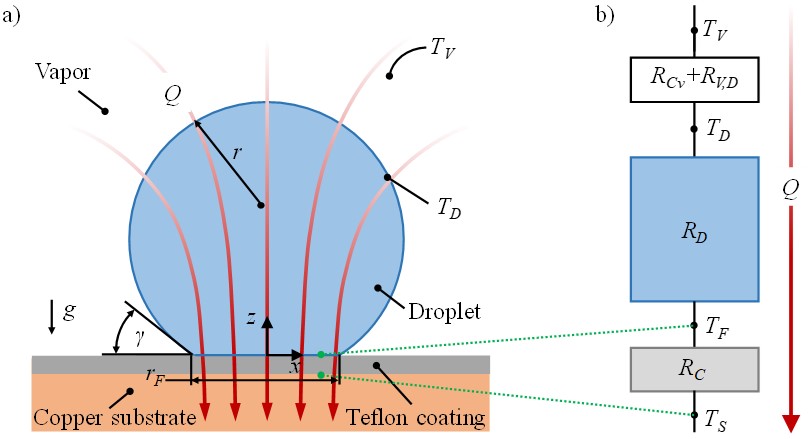

Drop-Wise Condensation (left); Theoretical model for heat transfer analysis on a single condensing droplet (right)

Our team focuses on the improvement of DWC by coating or treatment of the surface wall, using additives in the fluid, and modification of surface topography. Our general goal is the permanent generation of DWC through controlled nuclei initiation at continuous large contact angle with low hysteresis.

Selected research articles:

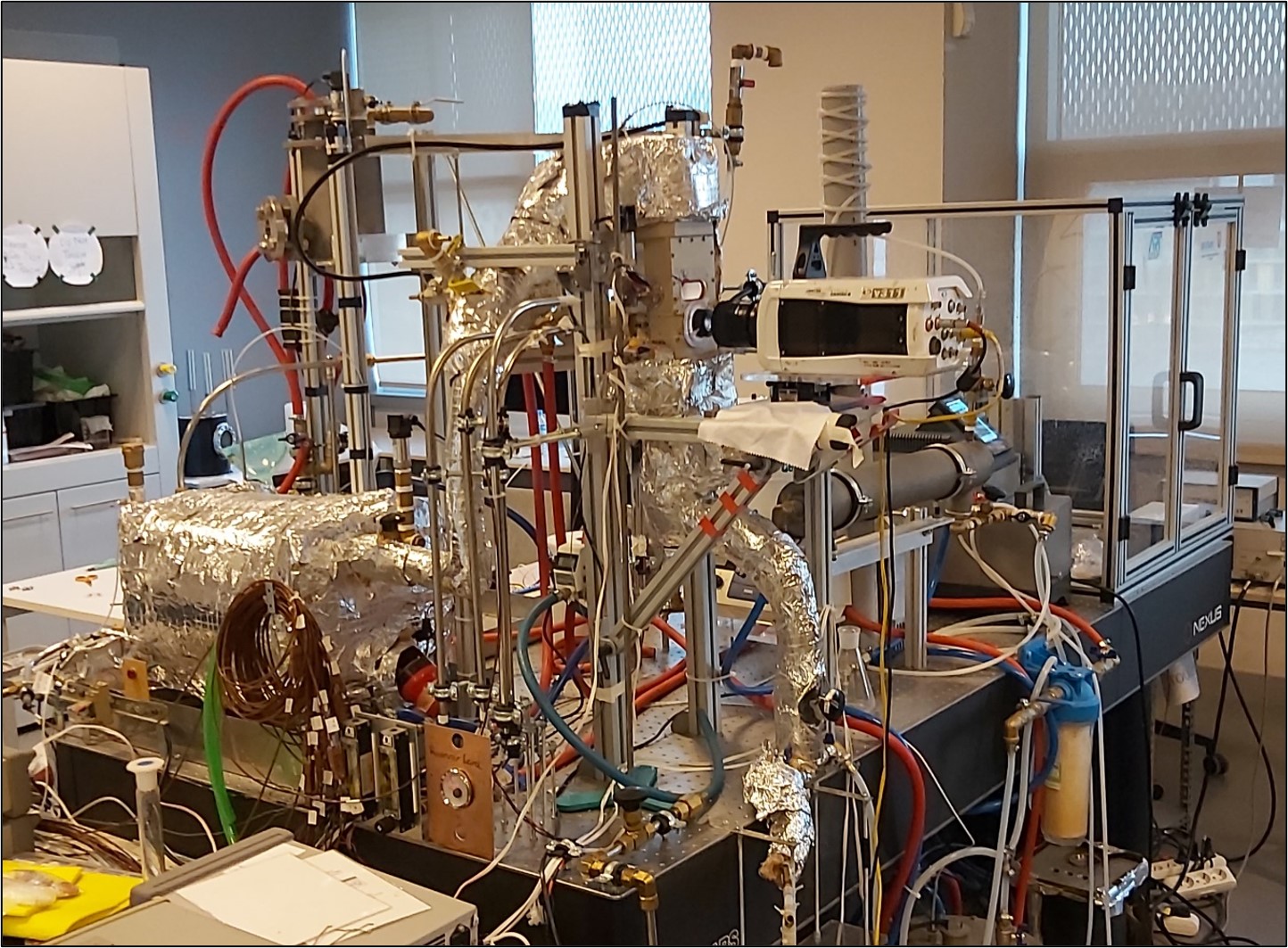

- An experimental study on the heat transfer and wettability characteristics of micro-structured surfaces during water vapor condensation under different pressure conditions

- On the individual droplet growth modeling and heat transfer analysis in dropwise condensation

- An experimental and theoretical analysis of vapor-to-liquid phase change on microstructured surfaces