- Fall 2024

Maximum Asphalt Pavement Thickness Designs

NCAT recently completed a project for the Alabama Department of Transportation (ALDOT Project 931-045) that developed a framework and recommendations for determining the maximum thickness of asphalt concrete (AC) in a flexible pavement during structural pavement design and evaluation. ALDOT, like most state agencies in the U.S., currently uses the 1993 AASHTO Design Guide for new pavement and overlay thickness design. Prior to this investigation, ALDOT did not have a process or policy on maximum asphalt pavement thickness that, in some situations, could lead to overdesigned pavement structures. Therefore, this study was conducted to accomplish the following objectives:

- Develop a methodology for ALDOT to determine maximum asphalt concrete thicknesses in a flexible pavement. The approach should serve as a design check of their existing pavement design policy and procedures.

- Verify the methodology using existing pavement sections in Alabama.

- Recommend ranges of maximum thickness for a range of ALDOT design conditions.

The investigation began with a review of existing state agency maximum thickness policies and procedures. A notable example is the Illinois DOT policy that utilized perpetual pavement concepts to determine maximum thickness as a design check at the conclusions of conventional thickness design. The framework and recommendations developed for ALDOT followed a similar approach but were customized for ALDOT using data from existing pavement sections in Alabama.

Data from 13 pavement sections in Alabama were used in the framework development phase to establish limiting strain criteria to ensure no structural bottom-up fatigue cracking. These sections were all interstate pavements with significant traffic levels. Perpetual pavement analyses were conducted on each, using PerRoad 4.4, to predict strain levels in the pavement relative to existing limiting strains to prevent bottom-up fatigue cracking.

These sections were all interstate pavements with significant traffic levels. Perpetual pavement analyses were conducted on each, using PerRoad 4.4, to predict strain levels in the pavement relative to existing limiting strains to prevent bottom-up fatigue cracking. While different moduli sets were used to represent the pavement layers, ALDOT default values provided the most reasonable results. Ultimately, it was found that existing perpetal criteria developed at the NCAT Test Track were adequate for design purposes and that most of the 13 sections had thicknesses exceeding the maximum thickness determined to provide perpetual status.

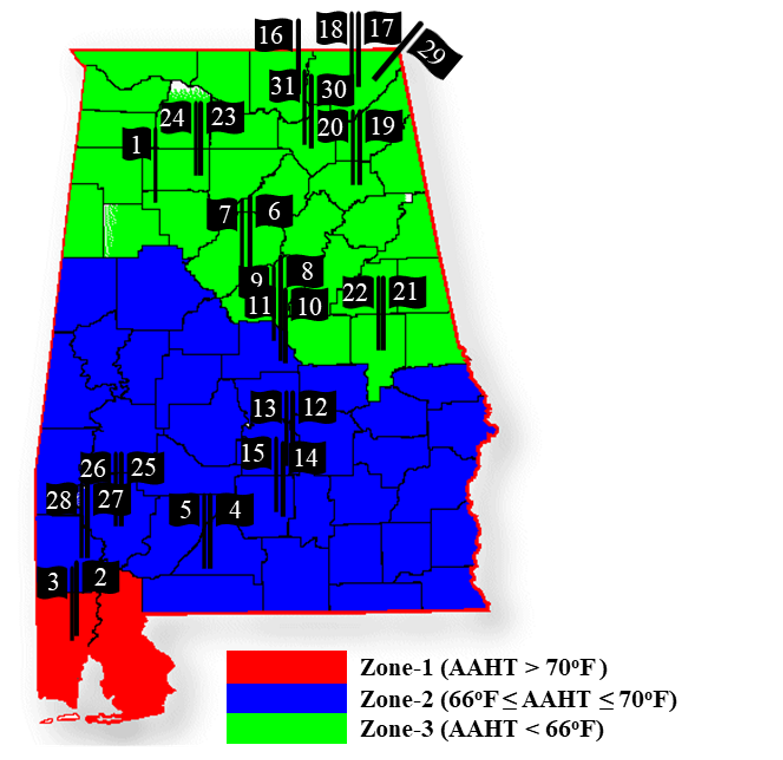

The validation portion of the study utilized data from an additional 31 pavement sections featuring both interstate and state routes in urban and rural environments distributed across the state. Three climate zones were established to account for temperature effects on the asphalt concrete layers. Figure 1 shows the zones, sections, and corresponding temperatures described by the average annual hourly air temperature (AAHT) in each zone. The criteria from the framework development phase accurately distinguished sections with structural bottom-up fatigue cracking in 30 of 31 cases, deemed sufficiently accurate for design. A key detail was the need to use legal axle load limits, rather than axle load spectra, when simulating the sections in PerRoad.

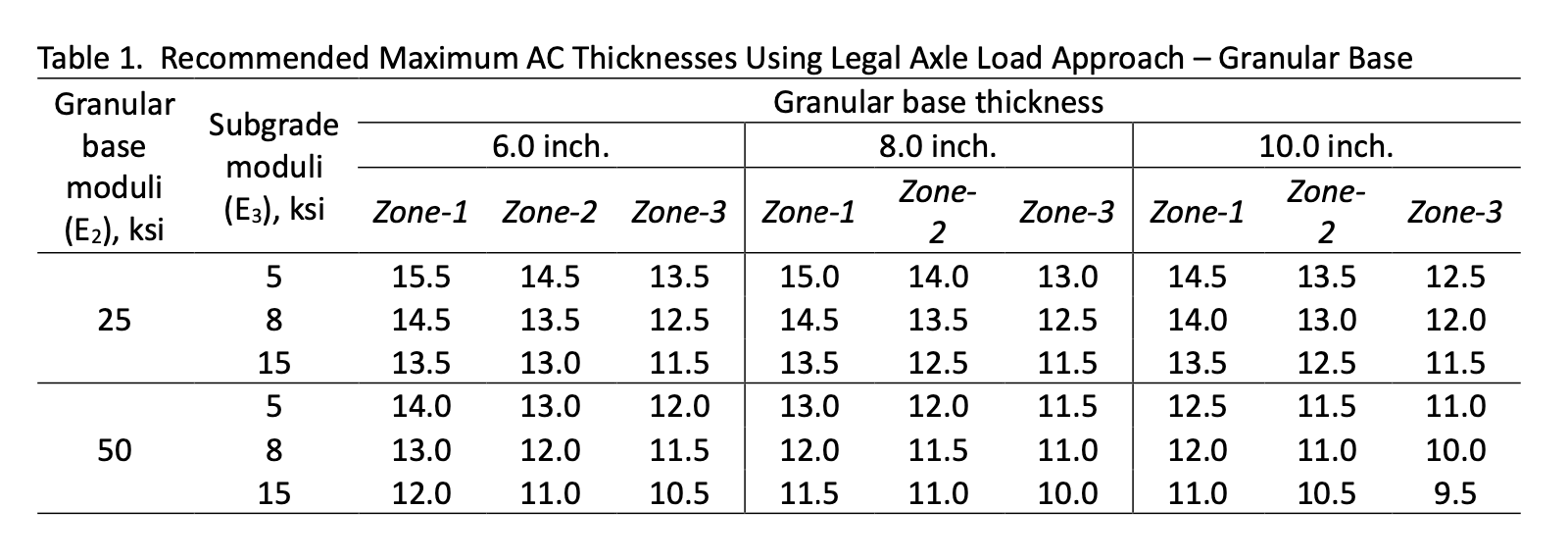

The final part of the study was to develop recommended maximum thicknesses using the framework that was developed and validated for a range of conditions. To that end, test cases were developed reresenting a range of soil and granular base moduli, granular base thicknesses, and the three climate zones from Figure 1. Table 1 shows the recommended maximum asphalt concrete thickness combinations of these factors. The worst-case condition in this table is for poor subgrade (5 ksi), with a 6-inch granular base with a modulus of 25 ksi, and the warmest climate zone (Zone 1) which yields a maximum AC thickness of 15.5 inches. The other end of the spectrum is a 9.5-inch maximum thickness for a pavement with the highest subgrade modulus (15 ksi), the thickest aggregate base (10 inches), and the highest granular base modulus (50 ksi) in the coolest climate zone (Zone 3). All other maximum thicknesses were between these two extremes.

Table 1 can serve as a design check for ALDOT after completing the AASHTO Design Guide process. If their thickness exceeds the value in Table 1 for specific conditions, it can be capped with confidence based on perpetual pavement design principles validated in Alabama. For designs outside the ranges in Table 1, the methodology developed in this study using PerRoad 4.4 can provide more specific maximum thicknesses. Both approaches could save ALDOT millions by avoiding overdesigned pavements from the AASHTO 1993 Design Guide.

Contact Dave Timm at timmdav@auburn.edu for more information about this research.