- Fall 2024

ALDOT’s Balanced Mix Design Field Validation Project

The Alabama Department of Transportation (ALDOT) continuously seeks innovative methods to enhance the safety, efficiency, and environmental soundness of the state’s transportation system. One way they are working toward that goal is improving the durability of Alabama’s asphalt pavements. Since 2022, ALDOT has been utilizing the Hamburg Wheel Track Tester (HWTT) to evaluate Superpave mix designs for traffic levels at or above 10 million equivalent single axle loads (ESALs) and all Stone Matrix Asphalt (SMA) mix designs. This helps assess resistance to rutting and moisture damage during the mix design phase.

Additionally, ALDOT is working to improve crack resistance using the IDEAL-CT test and is exploring a less time-consuming alternative to the HWTT for rutting—namely, the High Temperature Indirect Tensile Test (HT-IDT). ALDOT has begun benchmarking approved asphalt mix designs using both tests The construction of a field validation experiment, made possible by FHWA’s Accelerated Implementation and Deployment of Pavement Technologies program, marks another significant step toward implementation.

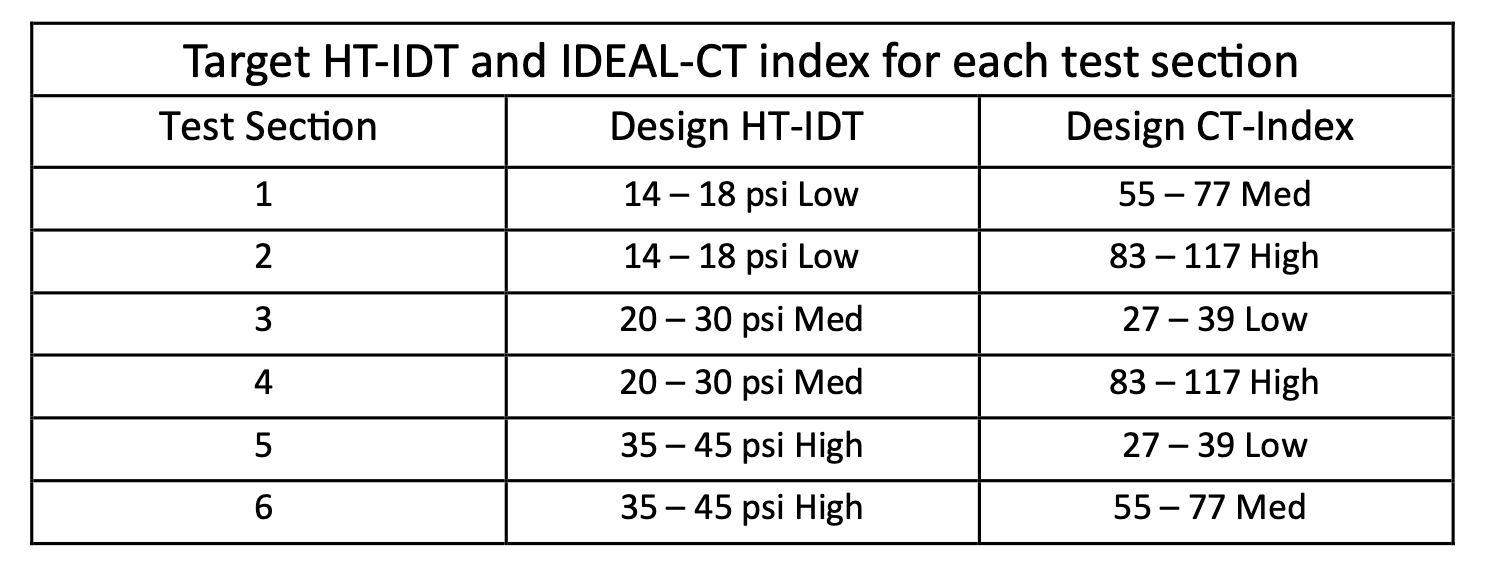

The Balanced Mix Design (BMD) field validation experiment includes six test sections along Alabama State Route 55, a rural, undivided four-lane highway in southern Alabama. This highway carries approximately 90% passenger cars, with predicted 20-year traffic projections at 3.55 MEASALs. The mill and overlay work were a typical ALDOT resurfacing project with 1.5 inches of micro milling, covered by 165 lb/sy of 3/4 in. MAS (1/2 in. NMAS) Superpave wearing surface. Each test section spans 1,000 feet and contains approximately 100 tons of mix designed to meet specific target ranges for the two mechanical tests being validated, as shown in Table 1.

Designing mixtures to meet these targets proved to be challenging, which fell exclusively on the contractor. When planning a project with complex design parameters, it is important to schedule extra time for the design and approval of the mixes. Approval for each test section was granted based on tests conducted by the ALDOT Central Laboratory using specimens mixed, aged, and compacted by the contractor. Acceptance of the test sections was determined by meeting ALDOT-approved volumetric targets.

Table 1. HT-IDT and IDEAL-CT design targets for each test section.

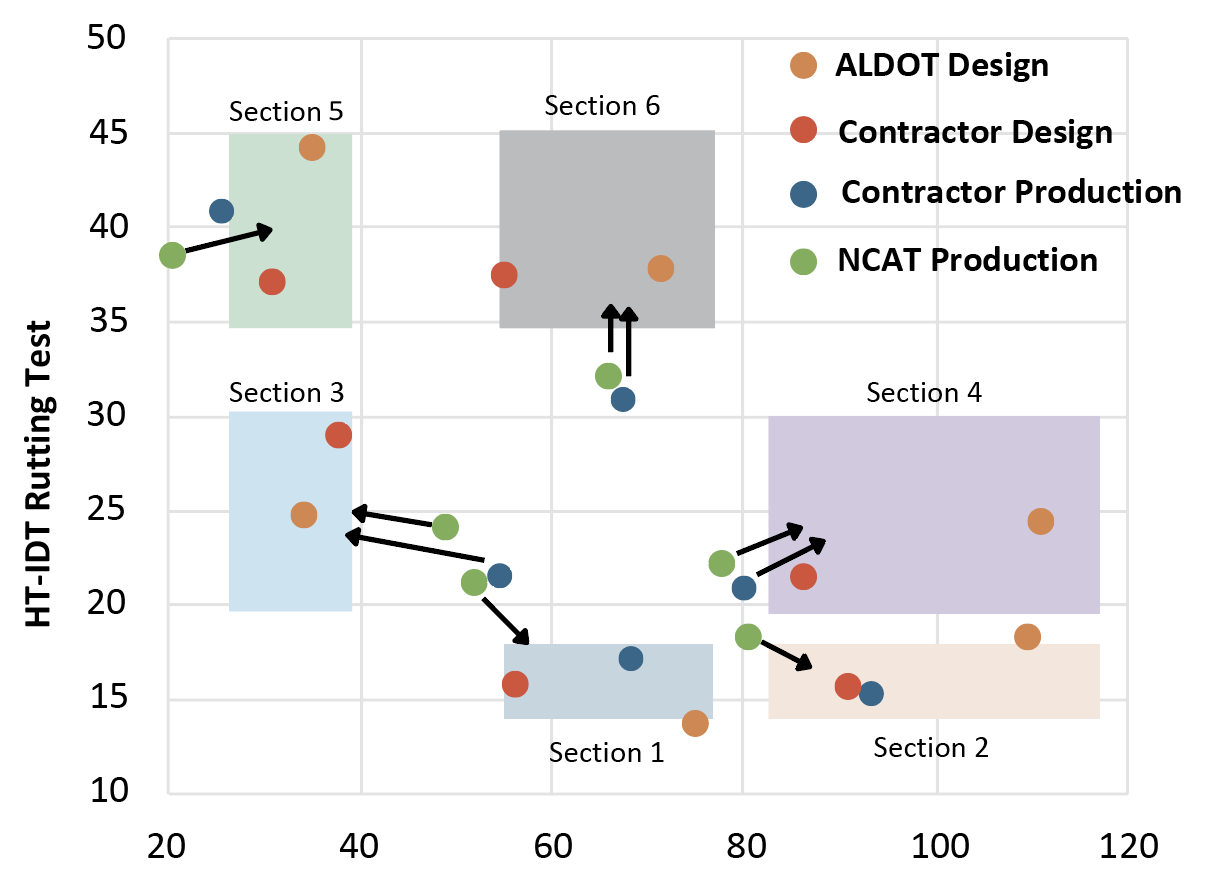

During construction, the mix was sampled and tested by the contractor and NCAT, which took its portable lab to the plant site. For four of the six mixtures, results for the plant-mixed, lab-compacted specimens differed from the lab-mixed, lab-compacted specimens tested in the mix design phase, and were outside of the target ranges from Table 1. In Figure 1 illustrates these target ranges (shaded areas) and the test results (dots) for each participant in the design or production phase. For results outside target ranges, arrows indicate the corresponding section.

Figure 1. HT-IDT and IDEAL-CT test results with section design targets.

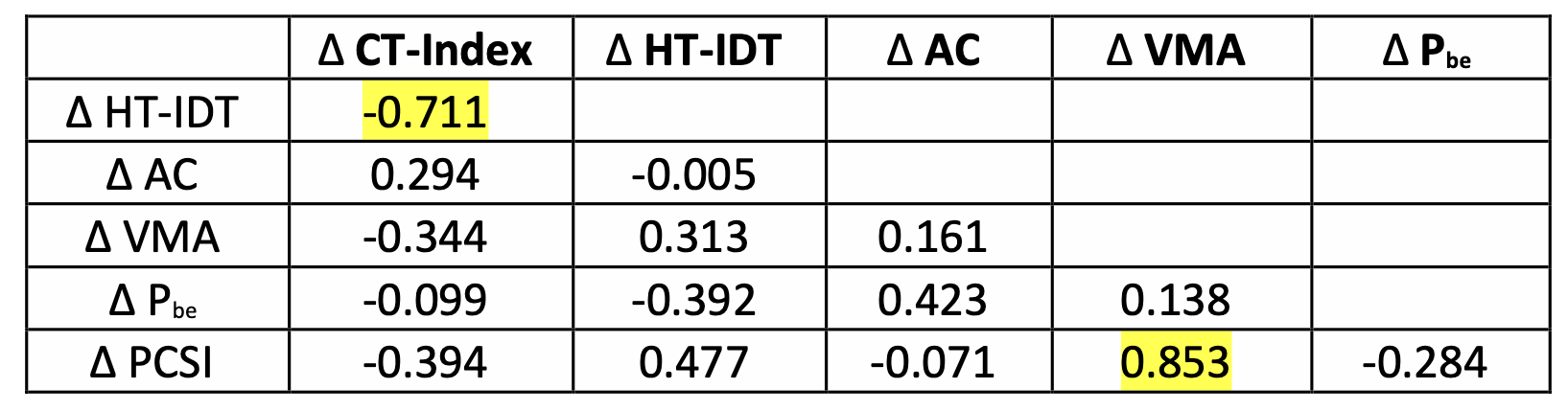

To understand why some mixtures’ test results shifted more than others from mix design to plant production, Pearson correlation analyses were conducted using the contractor’s data for IDEAL-CT, HT-IDT, AC%, VMA, Pbe, and Primary Control Sieve Index (PCSI). PCSI measures mix gradation fineness or coarseness by subtracting the percent passing the primary control sieve from the maximum density line. Correlation values with an absolute value greater than 0.6 indicate a strong correlation, while values above 0.8 indicate a very strong correlation.

Table 2 shows a strong inverse relationship between changes in CT-Index and HT-IDT, with a correlation of -0.711. Additionally, PCSI exhibited a very strong correlation with VMA, which was expected. However, the data did not show a strong relationship between changes in volumetric parameters and changes in performance test results.

Table 2. Pearson Correlation for all data points.

ALDOT will monitor test sections for cracking, rutting, and ride quality through annual surveys by Pathway Services. Distress data will be compared with mechanical test data from the asphalt mixtures to guide future implementation decisions.

Special thanks to ALDOT’s Materials and Tests Bureau, Construction Bureau, Office Engineer Bureau, ALDOT Troy Area, and Wiregrass Construction for making this project a reality, and to Dr. Chen Chen (NCAT) for statistical analysis and commentary.

Contact Zane Hartzog at zch0001@auburn.edu for more information about this research.