- Fall 2024

Comparative Life Cycle Assessments of Alternate Designs

In an era of heightened environmental awareness, greater attention is being given to how the construction and maintenance of transportation infrastructure impacts ecosystems and climate change. FHWA has been at the forefront of this effort, providing tools like LCApave to help state agencies, industry, and other stakeholders conduct Life Cycle Assessments (LCA) for pavement materials and design alternatives. LCA is a well-established methodology used to quantify the environmental impact of products, processes, or systems over their entire life cycle—from raw material extraction to end-of-life disposal. By providing a comprehensive view of environmental stressors, LCA helps identify areas where improvements can be made to reduce adverse impacts, such as global warming potential (GWP) and energy consumption.

A recent study at NCAT used LCApave to evaluate four alternate design and alternate bid (AD/AB) pavement projects in three states—Virginia, North Carolina, and Alabama—shedding light on the environmental implications of different pavement types.

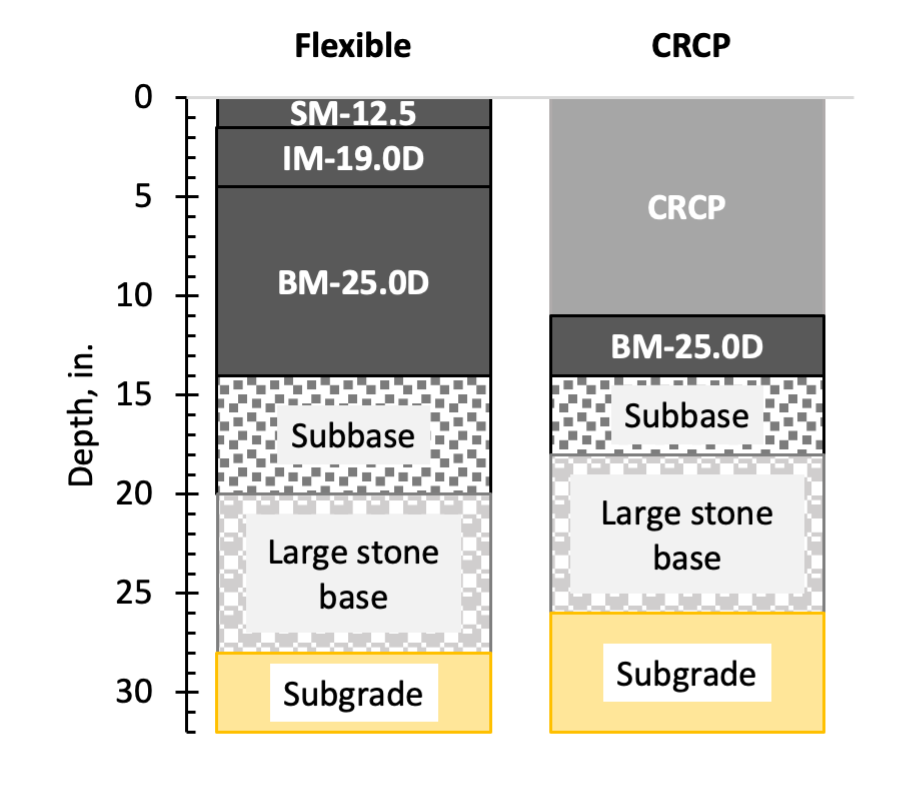

Figure 1a. I-81 widening project in Roanoke County, cross-section of the alternate designs.

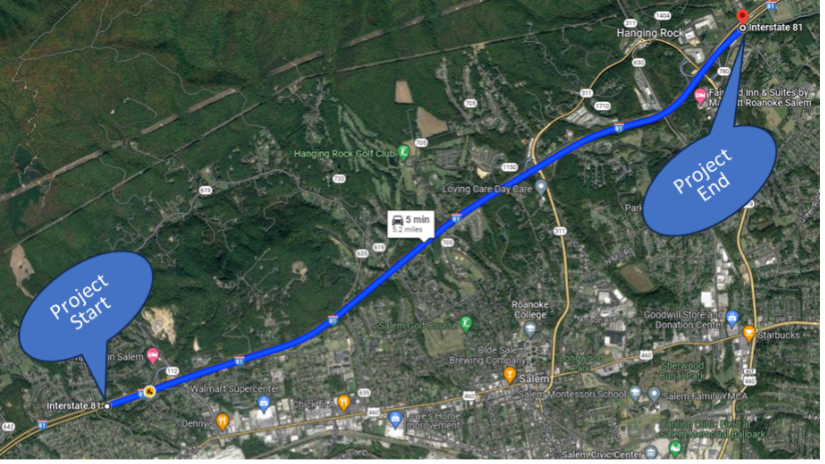

Figure 1b. I-81 widening project in Roanoke County, Virginia, geographic location of the project.

The study assessed cradle-to-grave environmental impacts of AD/AB pavement projects, focusing on conventional flexible and rigid pavement options. Both AD/AB projects are designed to have equivalent service life and performance, enabling a fair comparison of environmental impacts.

Data for the study were gathered from four AD/AB projects in the three states. This data included pavement structural design information and maintenance and rehabilitation (M&R) schedules, as outlined in each state’s Life Cycle Cost Analysis (LCCA) guidelines.

Figure 1 shows the AD/AB pavement design information for the I-84 widening project near Salem, Virginia. Similar AD/AB projects were analyzed on I-26 and I-240 highways in Ashville, North Carolina, and the US-411 highway near Centre, Alabama. The study utilized EPDs from NAPA’s Emerald Ecolabel program for asphalt concrete and the National Ready Mixed Concrete Association’s Industry-Wide EPD and Benchmarking Report v4.0 for Portland cement concrete, ensuring that the LCA was based on accurate and industry-relevant data.

This study utilized facility-specific asphalt concrete EPDs based on the NAPA Product Category Rule (PCR) for asphalt mixtures and industry-average Portland cement concrete EPDs developed under the National Science Foundation PCR. However, the compatibility of using EPDs from different PCRs requires further investigation. Additionally, emissions from the use stage (B2) were excluded from the comparative LCA due to the limitations of the LCApave tool, which presently does not account for this stage. Also, there is no agreed-upon methodology for estimating the use-phase emissions for pavements.

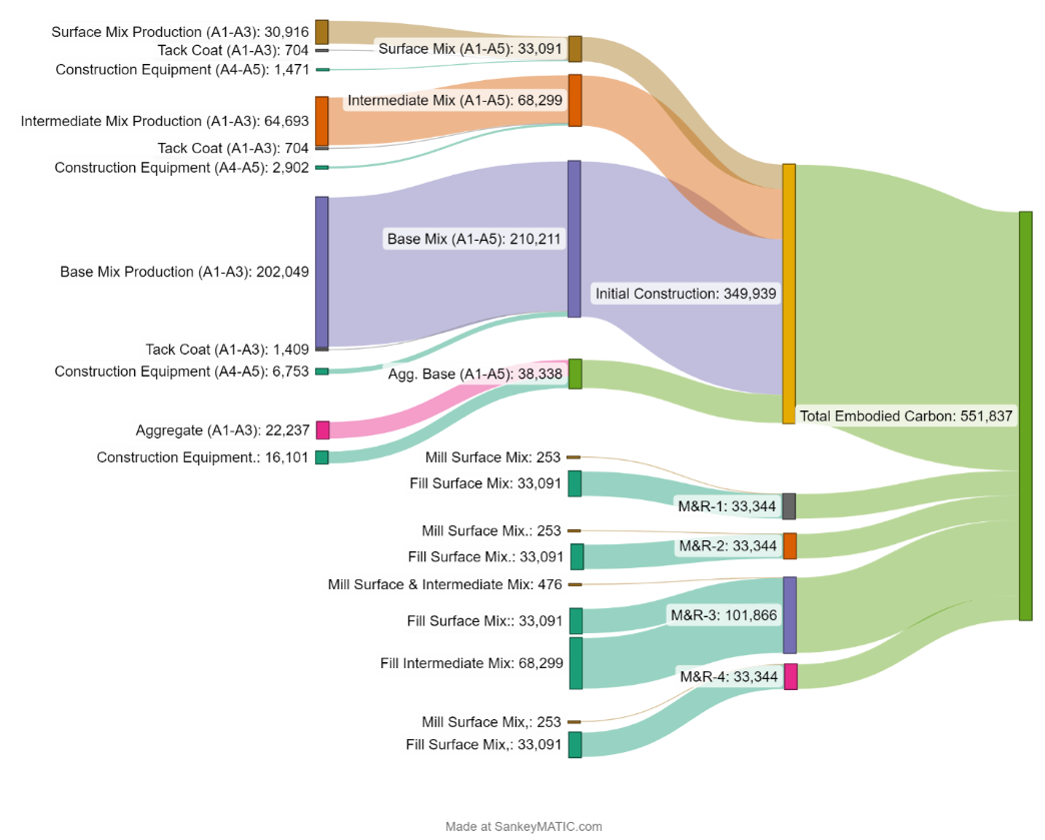

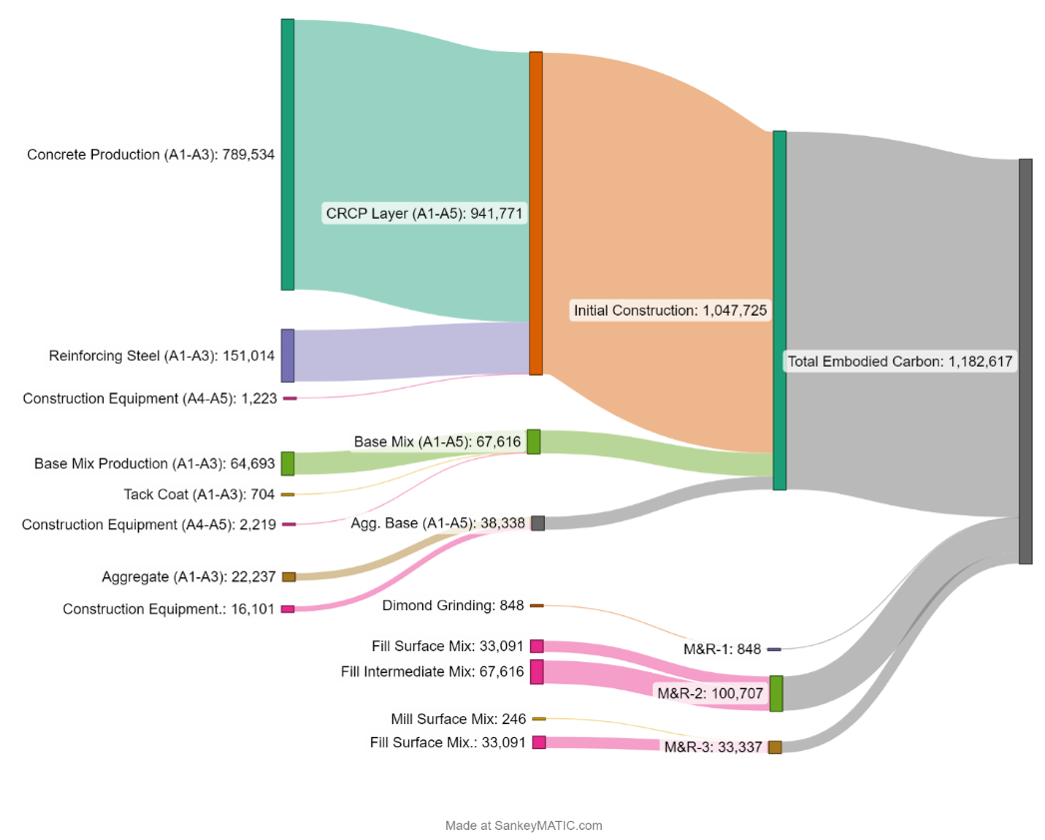

For flexible pavements, analysis of the LCA results indicates that 60 to 66% of greenhouse gas (GHG) emissions occurred during the initial construction stage, with 33 to 39% attributed to future M&R activities, as shown in Figure 2. In contrast, for rigid pavements, the initial construction stage accounted for 89 to 93% of GHG emissions, with only 7 to 9% resulting from future M&R activities, as shown in Figure 3.

Figure 2: Cradle to grave GHG emissions of flexible pavement alternative for the I-81 widening project (units = kg CO2e per lane-mile).

Figure 3: Cradle to grave GHG emissions of rigid pavement alternative for the I-81 widening project

(units = kg CO2e per lane-mile).

The study's findings highlight the environmental differences between flexible and rigid pavement types, revealing that rigid pavements generally have higher embodied environmental impacts across several key indicators:

- Acidification Potential: Rigid pavements have an acidification potential that is 1.6 to 2.8 times higher than that of flexible pavements. Acidification, caused by emissions of sulfur dioxide (SO2) and nitrogen oxides (NOx), can lead to acid rain, harming ecosystems and human health.

- Eutrophication Potential: Rigid pavements were found to have a eutrophication potential 9.3 to 12.5 times higher than flexible pavements. Eutrophication from nutrient pollution can cause harmful algal blooms and oxygen depletion, severely impacting aquatic life.

- Global Warming Potential (GWP): The GWP of rigid pavements was 1.9 to 3.1 times higher than that of flexible pavements. This measure indicates the amount of heat trapped in the atmosphere by greenhouse gases, contributing to global climate change.

- Ozone Depletion Potential: The ozone depletion potential of rigid pavements was found to be 20 to 20.3 times higher than that of flexible pavements. Ozone depletion increases harmful UV radiation reaching Earth, leading to skin cancer and other health issues.

-

Smog Formation Potential: Rigid pavements had a smog formation potential that was 1.6 to 2.3 times higher than flexible pavements. Smog, primarily caused by the reaction of sunlight with pollutants like volatile organic compounds (VOCs) and NOx, can lead to respiratory issues and other health problems.

The findings from this study have important implications for future pavement design and policy decisions. As the transportation sector continues to focus on reducing its environmental footprint, incorporating LCA into the decision-making process will be crucial. Tools like LCApave provide the necessary data and insights to make informed choices that consider performance and environmental sustainability. In conclusion, this study highlights the need for a holistic approach to pavement design, one that considers both life cycle costs and environmental impacts. By doing so, the industry can move toward more sustainable infrastructure solutions that meet the needs of both current and future generations.

Contact Suri Gatiganti at szg0094@auburn.edu for more information about this research.