- Fall 2024

Technologies to Mitigate Aging Effects on Asphalt Binder

Untreated wood could be used for making outdoor furniture, but exposure to rain, sun, and varying temperatures will cause it to warp, crack, and decay quickly. To enable outdoor furniture to withstand harsh elements for years, treated wood is commonly used, as it goes through a process where chemicals are infused into the wood to help it resist decay, insects, and weathering. To extend this concept to asphalt pavements, a new category of additives has been explored to boost asphalt mixtures' resistance to aging from UV radiation, oxidation, and temperature fluctuations, keeping them flexible and durable longer.

A research project funded by the FHWA Exploratory Advanced Research Program was aimed to identify aging-resistant technologies that could mitigate the damaging effects of aging on asphalt binders and mixtures. In this project, NCAT and GHK partnered with five industry collaborators—Blacklidge Emulsions, Chemco Systems, Iowa State University, Kraton Corporation, and Lehigh Technologies—to evaluate five candidate aging-resistant additives, each with a Technology Readiness Level (TRL) of 2 or 3:

Additive 1: A thermosetting two-phase chemical system composed of Phase A, which is an epoxy resin, and Phase B, which is a base asphalt binder with an epoxy cross-linker.

Additive 2: A hybrid system of ground tire rubber (GTR) powder and a polymeric compound.

Additive 3: A hybrid anti-aging technology system consisting of a high polymer content continuous phase styrenic block copolymer and a pine-based chemical recycling agent.

Additive 4: A bio-derived polymer made from epoxidized soybean oil.

Additive 5: A proprietary blend of biosynthetic, petroleum-based, and rheology modifiers.

Laboratory work included three experiments. The first experiment selected two base binders to assess the effectiveness of the aging-resistant additives. The second experiment examined the rheological and chemical properties of the base binders and their blends with each additive and recycled binder before and after exposure to oxidation and UV radiation. Finally, the third experiment focused on asphalt mixtures, testing their resistance to cracking and simulating the potential life-extending benefits of these additives using the pavement analysis software FlexPAVE™ developed by North Carolina State University.

In the first experiment, six base binders from different sources were evaluated, and two base binders were selected: Binder 1 (PG 64-16, from the South Central United States) and Binder 5 (PG 64-28, from Western Canada). They represent the wide range of rheological and aging behaviors in North American asphalt binders. Although these binders have a similar high-temperature performance grade (PGH), their aging behavior and chemical composition differ. After Rolling Thin Film Oven (RTFO) and 20-hour Pressurized Aging Vessel (PAV20) aging, Binder 1 is m-controlled with low-temperature performance grade (PGL) of -16oC and ΔTc = -6.2°C, while Binder 5 is controlled by stiffness with PGL of -28oC and ΔTc = +0.4°C, differing two PGL grades from Binder 1. After RTFO and 60-hour PAV (PAV60) aging, the ΔTc of Binder 1 drops to -14.7°C, whereas the ΔTc of Binder 5 was -3.9°C, which is better than the ΔTc of Binder 1 after RTFO and 20-hour PAV aging.

In the second experiment, the five aging-resistant additives were evaluated by comparing the modified binders with each additive to the respective neat base binders and their blends with recycled binder after RTFO, 60-hour PAV, and UV aging. A comprehensive suite of rheological and chemical tests were conducted on these binders and their blends. The results showed that the effectiveness of the aging-resistant additives varied based on the base binder and, in some cases, the presence of recycled binder. All five additives helped reduce the negative effects of aging in neat binders and their blends with the recycled binder. However, they proved more effective in Binder 1 with poor relaxation properties (m-controlled, more negative ΔTc), where improvements in the phase angle directly translated to better low-temperature performance. Although no direct evidence indicates that these additives slow oxidation kinetics, they may offer significant benefits in stabilizing Binder 1, especially when blended with recycled binder.

While the additives were likely selected for their aging-resistant potential to disrupt and decelerate oxidation, which leads to the formation of ketones (carbonyl groups), the complex nature of asphalt oxidation has long resisted a purely chemical solution. Instead, the most practical strategy appears to be using age-stable rheological modifiers that restore molecular mobility and enhance relaxation properties where they are needed most. Findings from the second experiment showed that formulating a rheology modifier (i.e., an additive that alters the flow and deformation behavior of the asphalt binder) can be challenging, but a few guidelines may help:

- Improve ΔTc by increasing the binder phase angle as much as possible for any given binder modulus.

- Soften the binder without sacrificing PGH, but try to improve ΔTc. Consider bio-based or aromatic/naphthenic petroleum-based oils. Do not use saturated fats, aliphatic oils, or waxes that precipitate/crystallize at low temperatures or create compatibility issues with asphaltenes.

- Protect the ΔTc-enhancing additive during extended aging by choosing stable modifiers that will not degrade substantially or crosslink over time. Mono-unsaturated fats with protected or crosslinked double bonds are usually the best bio-based additives. Beware of polyunsaturated fatty molecules if double bonds are not protected, and do not use heat-stable saturated fats that crystallize at low temperatures.

- Add polymer modifiers to regain lost rutting resistance if more rejuvenator oil is needed to restore and preserve relaxation. Also, polymers can be used to improve binder failure strains at low temperatures. When used as a parameter for cracking specifications, ΔTc may unfairly penalize polymers. This deficiency can be corrected with a test for failure properties.

- Recycled binders are a valuable resource, but mixtures with high recycled contents require careful control of relaxation properties.

The third experiment assessed the effect of five additives on the resistance of asphalt mixtures to aging and fatigue resistance. The experiment compared the cracking resistance of asphalt mixtures modified with each additive to the respective unmodified mixtures using the Dynamic Modulus (|E*|) and Cyclic Fatigue tests under three aging conditions, including short-term oven aging (STOA) on the loose mix, long-term oven aging (LTOA) on the loose mix, and the NCAT Accelerated Weathering System (NAWS).

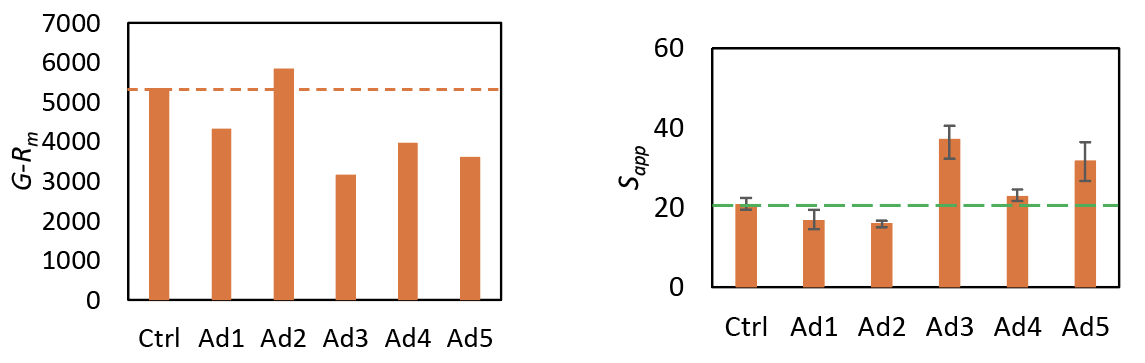

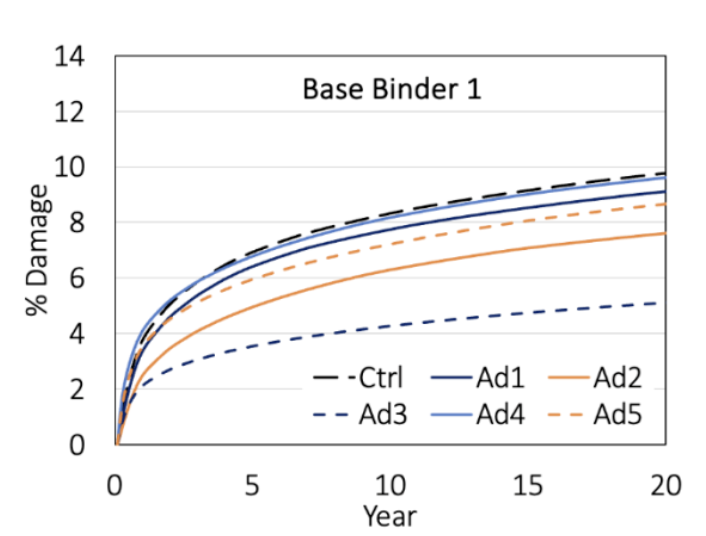

From those tests, the mixture Glover-Rowe parameter (G-Rm) and black space diagrams were determined to evaluate each mixture's resistance to cracking. The Cyclic Fatigue test, in conjunction with the |E*|, was also used to evaluate the damage accumulation characteristics of each mixture under different aging conditions. This assessment was based on the fatigue cracking performance parameter, Sapp, and predicted pavement fatigue damage using FlexPAVE, considering the effects of short-term aging properties, traffic, climate, and pavement structure. An effective additive would lower the G-Rm parameter, increase the Sapp parameter, and reduce fatigue damage. As shown in Figure 1c, the use of some additives positively reduced the fatigue damage in the simulated pavement structure. However, the degree of improvement in mechanical properties and aging resistance varied depending on the additive and the base binder used in the mixtures, as illustrated in Figures 1a and 1b.

Figure 1a. Pavement analysis G-Rm parameter, LTOA.

Figure 1b. Pavement analysis Sapp parameter, LTOA.

Figure 1c. % Fatigue damage by FlexPAVE, STOA.

This study introduces a new classification of additives that can help improve the aging resistance and durability of asphalt mixtures. It also provides a framework for evaluating such additives that could improve the long-term performance of asphalt pavements.

Contact Raquel Moraes (left) at moraes@auburn.edu or Nam Tran (right) at nam.tran@auburn.edu for more information about this research.