- Fall 2024

Open-Graded Friction Courses Suitable for Suburban Areas

An open-graded friction course (OGFC) is a unique asphalt mixture designed with a gap-graded gradation and high air void content (i.e., 15% to 22%), which allows water to drain from the pavement surface and laterally through the OGFC layer. OGFCs are used by relatively few state DOTs to enhance skid resistance, reduce hydroplaning, and splash and spray from tires during wet weather. For decades, the Florida Department of Transportation (FDOT) has used OGFC mixtures, called FC-5, for pavements with a design speed of 50 mph or greater on roadways without curbs and gutters, except for areas with a documented history of wet weather accidents. In some cases where FC-5 has been used, the pavements are subject to high lateral stresses from moderate-speed turning movements and rapid acceleration and braking, causing premature reveling of the layer. Therefore, research was needed to improve the durability of OGFC mixtures or develop a more durable alternative friction course suitable for suburban environments in Florida.

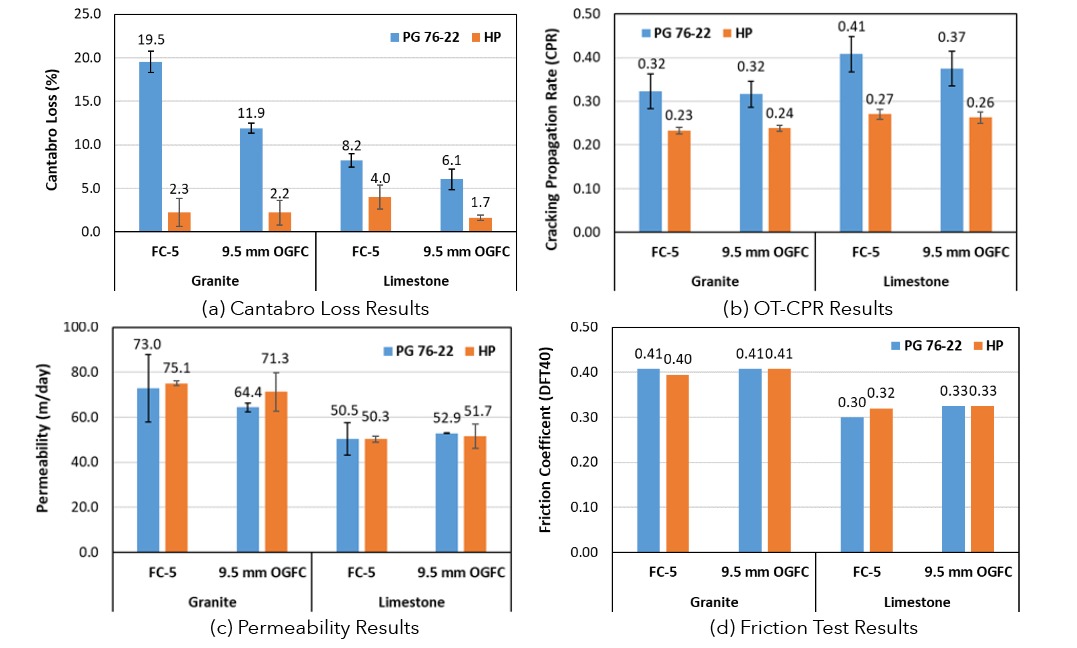

First, this study evaluated the feasibility of a smaller nominal maximum aggregate size (NMAS) gradation (i.e., 9.5 mm NMAS) and high polymer (HP) modified binder to improve the durability of OGFC in suburban environments while maintaining permeability, cracking resistance, and friction properties. Laboratory tests were conducted on FC-5 and 9.5 mm OGFC mixes prepared with two aggregate types (granite and limestone) and two asphalt binders (PG 76-22 and HP). The optimum binder content (OBC) difference between FC-5 and 9.5 mm OGFC mixes were 0.0% and 0.3% for granite and limestone, respectively. As shown in Figure 1, the HP mixes had significantly better durability and cracking resistance regarding Cantabro loss and Overlay Test (OT) crack propagation rate (CPR) results, respectively. The test results also show that using the smaller NMAS gradation significantly improved the durability without affecting the cracking resistance, permeability, and friction properties.

Figure 1. Laboratory performance test results of FC-5 and 9.5 mm OGFC mixes.

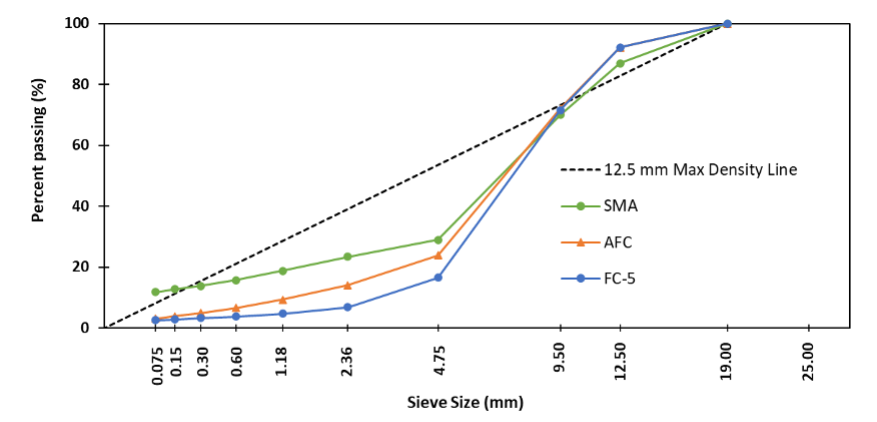

While raveling is common in OGFC layers, it is not typically observed in Stone Matrix Asphalt (SMA) mixtures with superior durability and rutting resistance. The SMA mixture has finer gradation than the OGFC mixture, which is part of the reason for the superior durability and impermeable surface. Inspired by the performance of OGFC and SMA mixtures, the research team developed an alternative friction course (AFC) mixture with balanced durability and permeability by adjusting the blend gradation. The AFC mixture is designed based on FC-5 and SMA mixtures with the same NMAS (i.e., 12.5 mm). Specifically, the gradation of AFC is designed to be between FC-5 and SMA to provide durability and permeability, as shown in Figure 2. The AFC mix's optimum binder content (OBC) is determined to meet the maximum Cantabro loss criterion of 10% while achieving a significantly higher permeability than the corresponding SMA mix.

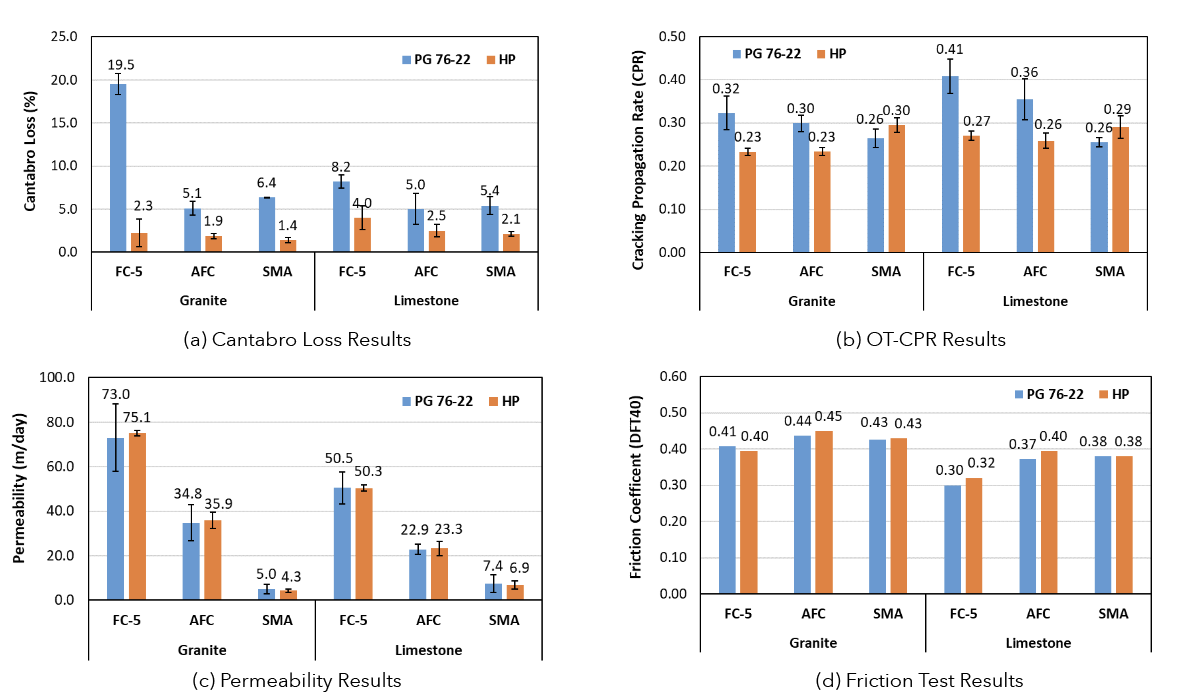

After developing AFC mix designs, all three mixes (FC-5, AFC, and 12.5 mm SMA) were prepared with two aggregate types (granite and limestone) and two asphalt binders (PG 76-22 and HP). A series of laboratory performance tests were conducted to compare the mixture performance and functionality among three mix types. Note that the OBC of AFC mixes were between those of FC-5 and SMA mixes, which is 0.2%-0.3% higher than the OBC of FC-5 mixes. As shown in Figure 3, the AFC mixes generally had better durability, cracking resistance, and friction than FC-5 mixes while maintaining adequate permeability for both aggregate types. Notably, AFC mixtures had comparable durability and cracking resistance to SMA mixes.

Figure 2. Illustration of AFC gradation design.

Based on Cantabro tests, the AFC mix has better durability than the FC-5 mix while maintaining reasonable permeability and safety characteristics, which can be a potential option to replace the existing FC-5 mix for suburban environments in Florida. These requirements include the gradation band, Ndesign, air voids, and maximum Cantabro loss. The preliminary OBC can be determined based on the Pie Plate Method per FM 5-558 and further verified by the proposed criteria, with the air voids (vacuum seal method) ranging from 10% to 15% and a maximum Cantabro mass loss of 10%. In addition, the Ndesign of 50 gyrations is proposed for the AFC mix, the same compaction level currently used for the FC-5 mix design.

Figure 3. Laboratory performance comparison among three mixes.

Contact Chen Chen at czc0105@auburn.edu for more information about this research.