Biological Education Research Lab or BERL is a series of research laboratories and support spaces that will allow the Biosystems Engineering program to fully realize its potential. The building was spatially reconfigured and updated with new mechanical, electrical, plumbing, and fire protection systems. The new renovation will significantly enhance laboratory safety and accessibility for all.

The laboratory houses analytical equipment for research on bioenergy, biobased products, and food engineering.bioanalyticalCurrent projects conducted in the lab focus on physical and chemical properties of bioenergy crops, rheological properties of southern forest biomass, off-gassing during biomass storage, and degradation in rheological properties of vegetable oils during frying.

Laboratory Equipment:

- Thermogravimetric analyzer (TGA)

- Differential scanning calorimeter (DSC)

- Color spectrophotometer

- Near-infrared (FTNIR) spectrometer

- Fourier transform infrared spectrometer (FTIR)

- Atomic force microscope (AFM)

- Rheometers

- Viscometer

- Bomb calorimeter

The Laboratory is currently being developed to support research on biological and ecological systems for the provision of fuels, food, and ecosystem services. The research will include the development of methods and procedures for the cultivation of algal biofilm systems for pollution recovery and biomass production for valuable products such as biofuels or pharmaceuticals.

Research in the laboratory will focus on the techniques for the culturing, cultivation, and processing of algal biomass for the provision of fundamental and secondary functional needs. The laboratory will be equipped to support the culturing of axenic, unialgal, and mixed algal communities, and will support research in assembly rules for sustainable complex microbial ecosystems for functional end-use. The laboratory will have the capabilities to measure and monitor the metabolism of microbial systems and employ that information for fine-scale control of culturing and cultivation processes.

To support these research efforts, the laboratory will include the latest in material and analytical capabilities to support the culturing of phototrophic microbial ecosystems of various attached and suspended physiologies at multiple scales. The laboratory will include a custom state-of-the-art laminar flow biofilm photobioreactor for the culturing of phototrophic biofilm communities, and an orbital mixing photobioreactor for the culturing of suspended phototrophic communities. These will provide the ability to culture and isolate different strains and communities of algae in mixed and uniagal consortia. Additionally, the laboratory will include a process-controlled bioreactor for finely-controlled metabolic culturing of heterotrophic microorganisms in aerobic and anaerobic conditions, which will allow investigation into biological downstream processing and refining of biomass for biofuel and nutriceutical products.

Laboratory Equipment:

- Flow-through photobioreactor metabolic chambers, instrumented with a Unisense microelectrode system, for precise measurement of biofilm metabolic characteristics

- Computer-controlled bioreactor

- UV/vis spectrophotometers to assess proteins, starches, and nutrient concentrations in biomass and growth substrate

- Fluorometer for assessing lipid, starch, and pigment content of algal biomass

- Lachat nutrient analyzer for rapid through-put of nutrient analyses on water used as a growth substrate

- Optical compound and dissecting microscopes for algal species identification and micro-structural biofilm analyses

The laboratory is used for the determination of physical and flow properties that are needed to design processing, characterization lab handling, and storage equipment for biological materials. Examples of projects conducted in the lab include optimizing storage vessel design for biomass feedstocks and physical treatments for ash reduction in biomass feedstocks.

Laboratory Equipment:

- Gas Pycnometers

- Humidity Chamber

- Powder Flow Testers

- Texture Analyzer

- Particle Size Image-based Analyzer (Camsizer)

- Laser-based Particle Analyzer

- Moisture Meters

The Biomaterials Processing and Conversion Lab is a flexible, shared-use lab that allows research on the size reduction and densification of conversion lab biomass, biomass pyrolysis, and gasification.

Laboratory Equipment:

- Fluidized bed biomass gasification reactor

- Biomass pyrolysis reactor

- High-pressure hydrothermal liquefaction unit

- Micro-channel Fischer-Tropsch reactor for syngas-to-liquid fuels production

- Online FTIR gas analyzer

- NOVA gas analyzer

- 2 Gas chromatographs

- Motorized exhaust snorkels

- Walk-in freezer

- Walk-in cooler

- Overhead crane

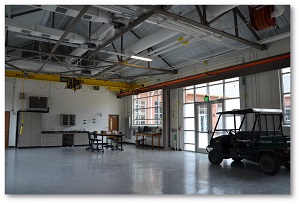

The laboratory supports research focused on off-highway machinery automation, the development of new technology to better place nutrients and pesticides, and solutions to harvesting and transporting cellulosic biomass. High-bay space allows automation operation and testing of large equipment such as Tier-4 tractor engines, nutrient and pesticide application equipment such as sprayers and fertilizer spreaders, and biomass harvesting systems. Equipment such as a PTO dynamometer is used in this space for engine testing and Control Area Network (CAN) data collection for evaluating fuel, power, and other parameters. The area will also contain a spray table providing the ability to evaluate deposition and droplet spectrum of spray tips. Finally, agricultural equipment can be positioned to study new sensor and instrumentation systems for monitoring machine performance on a geospatial basis.

Laboratory Equipment:

- John Deere 6420

- Caterpillar TimberKing HF221-Felling Head

- Variable-Rate Spinner-Disc Spreader

- Chandler Variable-Rate Fertilizer/Lime Spreader

- Chandler Variable-Rate Litter Spreader

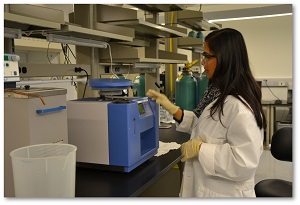

The laboratory provides analytical chemistry capability to support research activities related to biofuels, biobased materials, food engineering, and ecological engineering. This lab fills an important role in Biosystems Engineering by providing a functional, safe, and accessible laboratory for a wide range of chemical analyses. Prior to the renovation project, no chemical analysis capability existed in the Corley building complex.

Laboratory Equipment:

- 2 Gas Chromatographs

- Gas Chromatograph - Mass Spectrometer

- Pyroprobe

- High-Pressure Liquid Chromatography

- Thermogravimetric Analyzer

- Total Carbon Analyzer

- Incubator / Fermentor

- Roto-evaporator

- Viscometer

The main computing laboratory for biosystems engineering students is in Corley 314. The computer lab is one of the primary means of training students in the use of modern engineering and communication tools, to analyze critically scientific data, and to conduct engineering analysis. In 2019, the lab was expanded from 27 computer workstations (736 sqft) to 57 computer workstations (1299 sqft). The lab (Room 314) is equipped with four 80” TV monitors and a multimedia podium that can display different contents on each of the four monitors. Two video cameras in the room can project information shared on the whiteboard and document cameras, to students who are joining the class remotely. Students in all BSEN courses use this facility. There is a programmable electronic card reader door lock to ensure that only authorized users (students and faculty) have access to enter, through the central university access control office. There are an additional 5 computer workstations in the Student Design Studio Room (Corley 305) that students can use for academic work when the computer lab is being used for teaching.

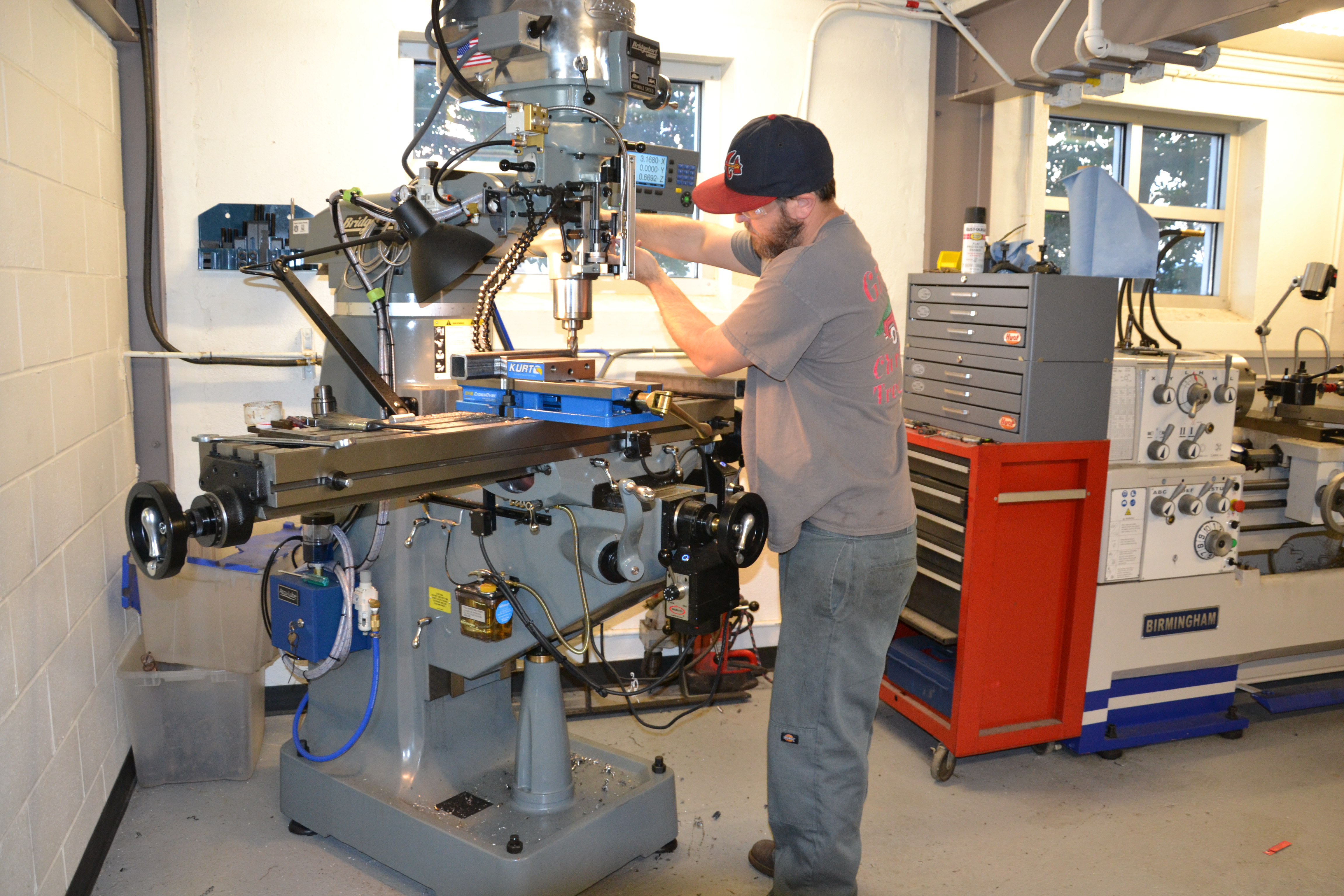

The fabrication shop and precision fabrication shop support the fabrication and repair of research equipment. The fabrication shop has the capability of doing all minor and major fabrication, including cutting, welding, steel punching, braking and shearing as well as allowing for storage of commonly used metals. The open floor space design of the laboratory provides adequate space for layout and mock-up of equipment during the design, construction, and assembly phases. The Precision Fabrication shop will have the capability of manufacturing custom and specialty parts.

Fabrication Shop Equipment:

- Welding Station with MIG and TIG Capabilities

- CNC Plasma Cutter

- Metal Worker

- Horizontal Band Saw

- Sheet Metal Shear and Brakes

- Drill Press

- Overhead Crane

- Motorized Snorkels for Exhaust