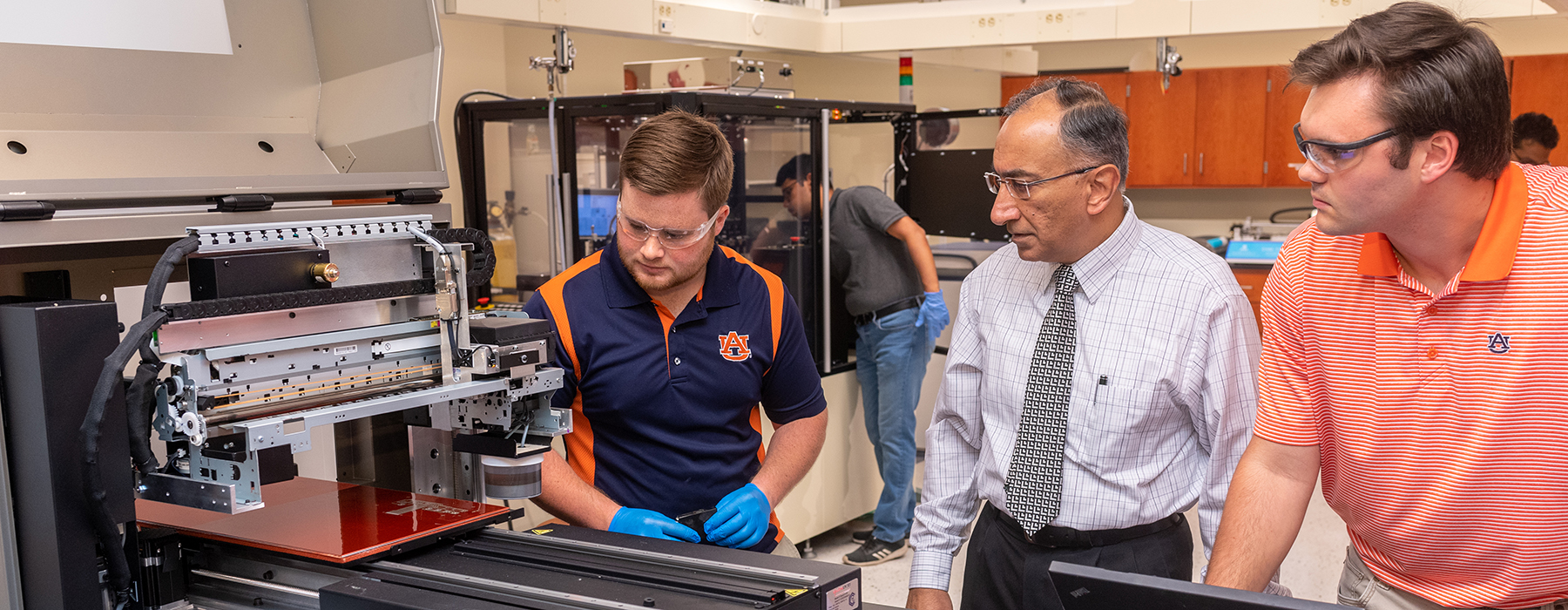

What is the Auburn University Electronics Packaging Research Institute or AUEPRI? Previously known as CAVE3, the institute started as an Industry and University Cooperative Research Program (I/URC). In 1999, a small seed grant from the National Science Foundation was utilized to help establish the research institute. Since its inception, AUERI has formed a number of long-term partnerships with industry, government, and academic agencies. The vast majority of funding for the institute currently derives from industrial partners. Since research topics are driven by an Industrial Advisory Board (IAB) comprised of member organizations, research results are directly applicable to their needs.

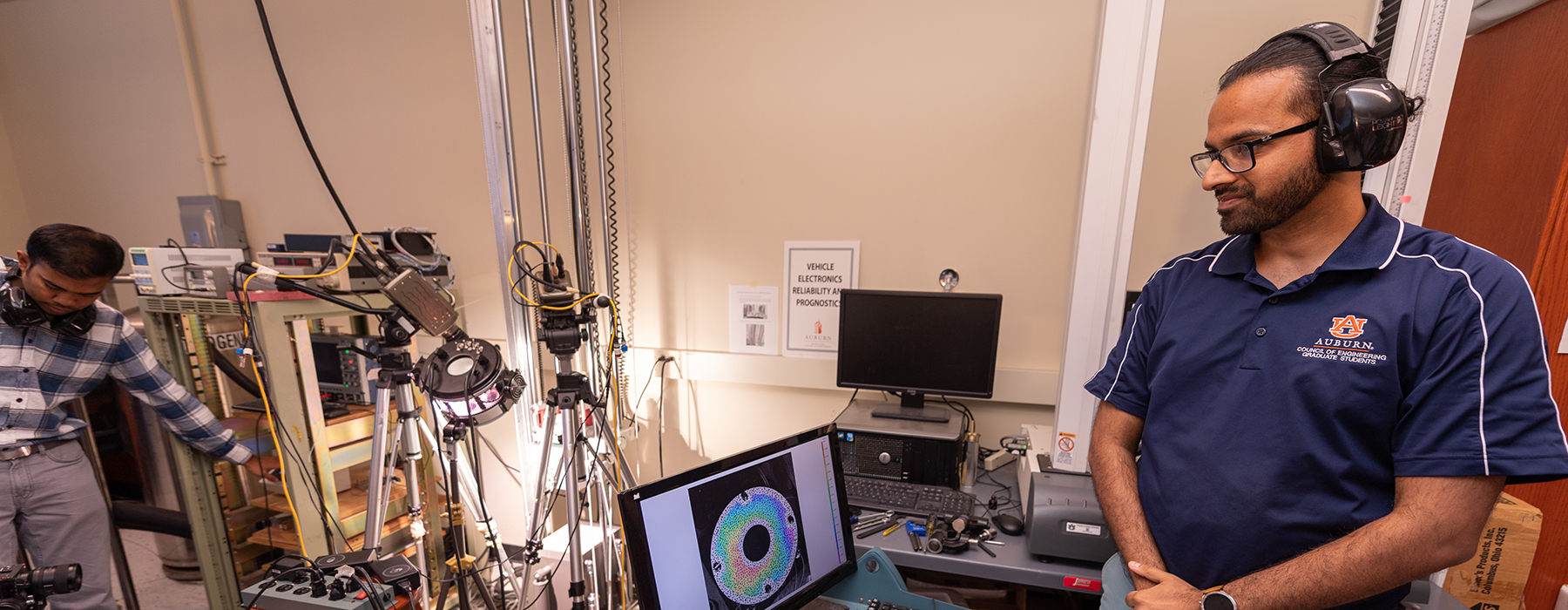

As electronic components become more prevalent in automotive and extreme environment applications, their reliability becomes an issue that requires costly recalls. Furthermore, when components are integrated into underhood applications, their temperatures range between -30° C and 175° C. However, they are still expected to last for 10 years/250,000 km (-22F to 350F and 150,000 miles). AUERI was founded to assist automotive and defense electronics suppliers and any entity with harsh environment electronics applications that need to meet their reliability requirements. From the very beginning of the institute's existence, it was acknowledged that other extreme environment applications shared a number of requirements with automotive electronics. Therefore, in 2009, its title was changed to NSF-CAVE3 Center for Advanced Vehicle and Extreme Environment Electronics from it initial founding title of CAVE. The CAVE3 Center has grown in size and areas of research. In 2024, the AU Board of Trustees approved the elevation of the CAVE3 Center to an Institute now called the Auburn University Electronics Packaging Research Institute. The updated name was intended to better communicate the Institute's areas of research and addresses the reliability challenges from harsh environments. Now, the institute is known as Auburn University Electronics Packaging Research Institute or AUERI.

Research areas cover challenges in:

- Semiconductor Packaging

- Chip Fabrication

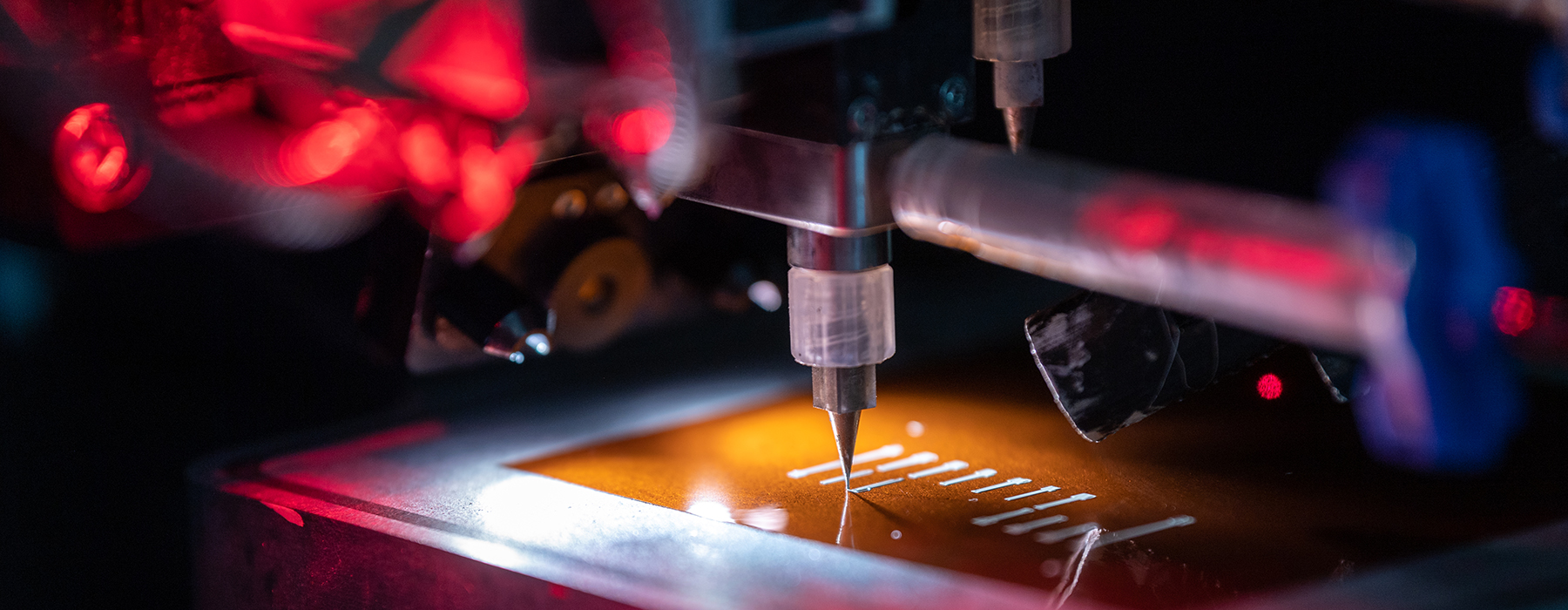

- Additive Printed Electronics

- Component Reliability

- Connector Reliability

- Flip Chip and Underfills

- Harsh Electronics System and Manufacturing

- Lead free Soldering

- Prognostic Health Management (PHM)

Bi-annual research reviews are hosted to communicate findings to member organizations. These are also implemented into a toolset entitled "E-tools," which allows member organizations to access extensive historical reliability and finite element-based simulation tools designed by AUERI researchers. The Institute offers a broad range of independent laboratory testing services and consulting to quantify the reliability of production prototypes and resolve manufacturing issues. All testing is in accordance with EDEC, ASTM, IPC, Military, UL, commercial, and customer specifications.

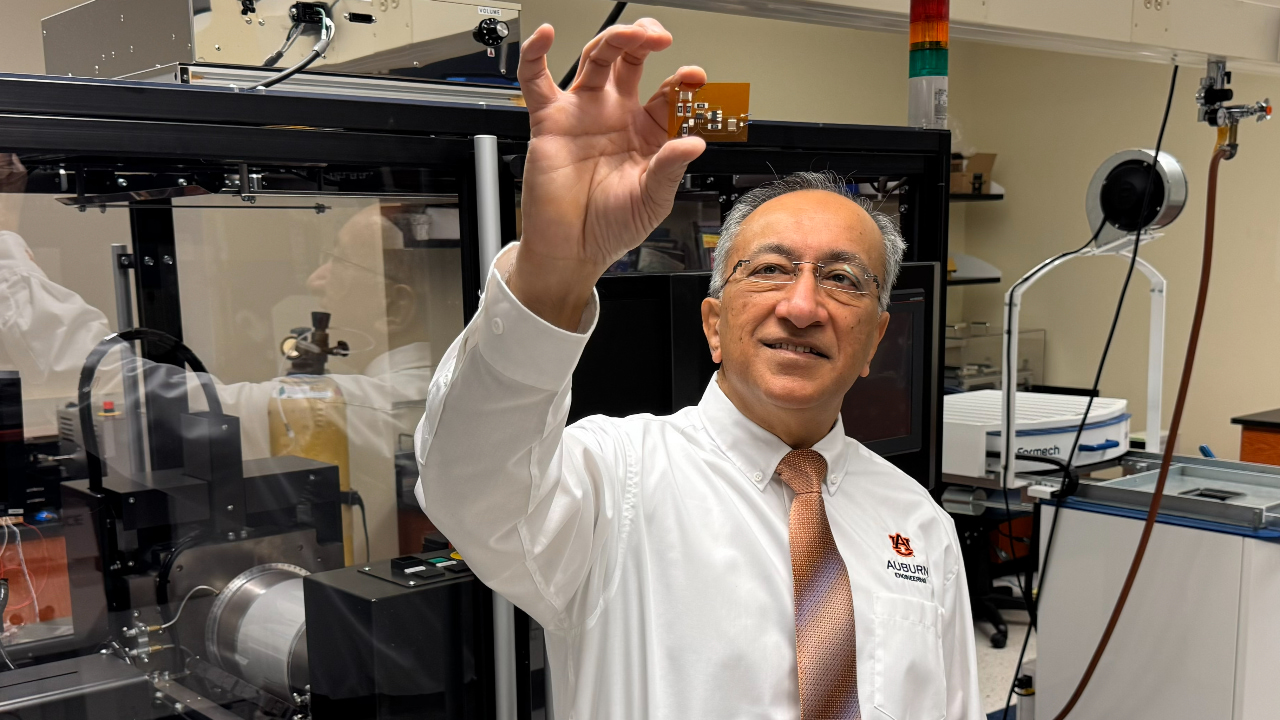

Message from the Director

Earlier in the fall semester of 2023, a number of AUERI researchers traveled to the SMTAI and the ASME INTERPACK conferences. The SMTAI was held in Minneapolis, MN, and the INTERPACK was held in San Diego, CA. I am glad to report that the following paper won the 1st Place Nasser Grayeli Best Poster Award:

Evaluation of Thermoformability of Additively Printed Circuits Printed Using Gravure Offset Printing Technique and Investigation of In-Mold Electronic Circuits, P. Lall, V. Soni, J. Narangaparambil, S. Miller, ASME InterPACK, Paper IPACK2023-112060, pp. 1-11, San Diego, CA, Oct 24-26, 2023. In addition, the following paper placed in the top 10:

Component Attach Process Recipe and Performance on Aerosol Printed Sustainable Silver Ink, Lall, P., Bimali, S., Narangaparambil, J., Miller, S., ASME InterPACK, Paper IPACK2023-112066, San Diego, CA, pp. 1-12, Oct 24-26, 2023. In October 2023, a number of AUERI students also presented their research at the Auburn Mechanical Engineering Graduate Poster Contest. In the Design and Manufacturing Track, Daniel Karakitie, Ved Soni, and Vishal Mehta placed 1st, 2nd, and 3rd respectively. In the Mechanics Track, Golam Rakib Mazumdar, Mahbub Alam Maruf, and Mrinmoy Saha placed 1st, 2nd, and 3rd respectively. In the Electric Vehicle, Electronics Packaging, and Electronic Thermal Management Track, Souvik Chakraborty placed 3rd. The student team continued their strong performance with a number of students winning IPC Scholarships, including Sabina Bimali, Padmanava Choudhury, Ved Soni, Daniel Karakitie, Vishal Mehta, Madhu Kasturi, Aathi Pandurangan, Fatahi Musa, Md Golam Sarwar, and Shriram Kulkarni. I am delighted to report that we have kicked off four new research programs since the last review. The first program, through a completely won SRC call, is on the topic of the study of Non-PFAS alternatives for use in electronics. Owing to impending regulation under the United States TSCA and the European Union REACH, there is renewed interest in the development and identification of alternatives for use in semiconductor packaging. In the current generation of electronics, PFAS is pervasive for a number of functions related to mechanical and electrical performance and reliability. The program, which spans 3 years, is in partnership with a number of SRC member companies including Intel, Texas Instruments, and IBM. The transition to Non-PFAS materials will impact all levels of packaging and processing from the chip to package, printed circuit boards, wiring, and modules. We are excited to be at the forefront of this challenge with the transition to more sustainable electronic materials. In addition, the AUERI team at Auburn University has kicked off three additional programs in the area of additively manufactured electronics under the latest selection of programs for award under Project Call 8. The first NextFlex program, PC8.2, is on the topic of additive packaging for high-temperature and quantum computing applications. In this program, the AU team is a major subcontractor to Boeing and will work on the development of manufacturing processes and material sets for operation under wide temperature extremes of -269°C to +500°C. In a second program, PC8.3, the Auburn-led team includes partners John Deere, Toyota Motors of North America, BayFlex, and MacDermid Alpha. The project will focus on exploring the process-performance-reliability interactions for in-mold electronics in automotive applications. Two specific automotive platforms for which the technology demonstrators will be created include the farming tractor and the crossover sport utility vehicle. In the third program, PC8.5, the Auburn-led team includes partners Tapecon and BayFlex and focuses on the development of sustainable additively manufactured electronics. A number of methods are being pursued to achieve sustainability, including the use of water-based inks, room-temperature processable interconnects, and biodegradable substrates. In addition to process development, the reliability of the assembled architectures is being studied in environments expected in wearable applications in wear-and-forget formats. In addition to kicking off new programs, we also concluded two programs including PC6.5 on the development of closed-loop control for inkjet additively manufactured electronics. The AUERI team, along with project partners, delivered the closed-loop control software developed under the program along with the hardware instrumentation to enable control of printed dimensions and electrical parameters in a manufacturing environment. In January 2024, we elected a new slate of officers for the AU-SMTA Student Chapter. The Director’s report at the Spring Review 2024 will have more details on the officers' names and designations. The officer team had a strong showing at the Auburn E-day, in which they staffed an SMTA booth to talk to high-school students about electronics manufacturing.