- Spring 2023

Validation of Rapid Rutting Test Procedures Using Plant Mixtures from the 2021 NCAT Test Track

Many State Departments of Transportation (DOTs) use either the Asphalt Pavement Analyzer (APA) or the Hamburg Wheel-Track Test (HWTT) during the mix design process to evaluate rutting resistance. Currently, eleven (11) State DOTs specify the APA during mix design and sixteen (16) State DOTs specify the HWTT during mix design.1 While these two tests are well-regarded and widely used for mix design, they are not considered optimal for use during routine quality control/quality assurance (QC/QA) testing. This is due to the longer conditioning and testing time required (i.e., 7 to 9 hours total) and the lack of equipment availability among industry contractors. There is a research need to select appropriate rapid rutting tests (RRT) for routine QC/QA testing during plant production.

Two promising RRT have been proposed for a production setting, which include the indirect tension test at high temperatures (HT-IDT) and the indirect tensile asphalt rutting test (IDEAL-RT). The indirect tensile strength (ITS) and rutting test index (RTIndex) are the rutting test parameters determined from HT-IDT and IDEAL-RT, respectively. Both HT-IDT and IDEAL-RT are rapid strength tests, which use an IDT fixture or a shearing fixture, respectively. These tests require only a short conditioning time (around 1 hour in a water bath) prior to the quick strength test (around 5 minutes for 3 replicates). Some preliminary studies indicated that both RRT showed good correlations with the two wheel-tracking tests (i.e., APA and HWTT) or limited field rutting performance.

During construction of the 2021 NCAT Test Track, NCAT further validated the two RRT using (14) fourteen unique Test Track surface mixtures with a wide spectrum of mixture components including different additives, binder types, binder contents, RAP contents, aggregate types, and aggregate gradations. The plant-mixed lab-compacted (PMLC) specimens for all mixtures were tested using the two RRT (i.e., HT-IDT and IDEAL-RT) and two wheel-tracking tests (i.e., APA and HWTT) to evaluate the mixture rutting resistance. Two aging conditions were evaluated – Production PMLC and Re-heated (RH) PMLC. Production PMLC specimens were compacted the same day as paving, while the re-heated PMLC mix was allowed to cool prior to being re-heated and tested later. APA testing was only conducted on RH PMLC specimens. The rutting test results were collected and analyzed to:

- evaluate the correlations among four rutting test parameters, and

- determine the preliminary threshold values of the rapid rutting parameters (i.e., ITS and RTIndex).

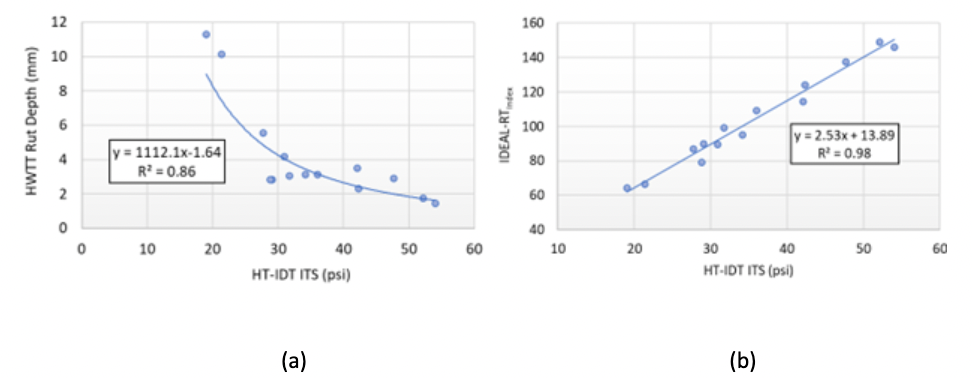

Pearson correlation analysis is used to investigate the relationship among the four rutting test parameters. Pearson correlation measures the strength of the relationship between two variables. The correlations indicated that there was a very strong linear correlation between HT-IDT ITS and IDEAL-RTIndex at both aging conditions, and HWTT rut depth had strong power correlations with two rapid rutting parameters (i.e., ITS and RTIndex), as shown in Figure 1. However, no strong correlation existed between APA rut depth and the other three rutting test parameters for the materials used in this study.

Figure 1. Examples of Correlations among Different Rutting Test Parameters; (a) Reheated HT-IDT ITS Vs. HWTT Rut Depth; (b) Reheated HT-IDT ITS Vs. IDEAL-RTIndex.

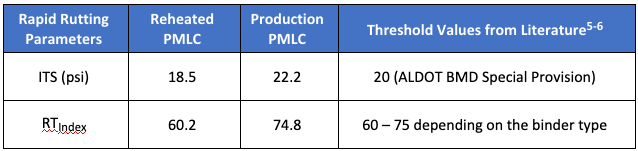

Based on the strong power correlations between HWTT rut depth and two RRT parameters, the preliminary threshold values of two RRT parameters corresponding to the HWTT rut depth criteria of 12.5 mm at 20,000 passes were determined at both aging conditions. As presented in Table 1, the preliminary threshold values of ITS for reheated and production PMLC are 18.5 psi and 22.2 psi, respectively. The preliminary threshold values for RTIndex are 60.2 and 74.8 for reheated and production PMLC mixtures, respectively. The existing threshold values of ITS and RTIndex parameters from the literature are generally consistent with the values obtained in this study. In the future, these test results can be compared against the eventual field rutting of these sections on the 2021 NCAT Test Track.

Table 1. Preliminary Threshold Values of ITS and RTIndex.

References

National Asphalt Pavement Association 2022, National Asphalt Pavement Association website, accessed July, 2022, https://www.asphaltpavement.org/expertise/engineering/resources/bmd-resource-guide.

Bennert, T., Haas, E., & Wass, E. (2018). Indirect Tensile Test (IDT) to Determine Asphalt Mixture Performance Indicators during Quality Control Testing in New Jersey. Transportation Research Record Vol. 2672(28), 394-403.

Zhou, F., Crockford, B., Zhang, J., Sheng, H., Epps, J., & Sun, L. (2019). Development and Validation of an Ideal Shear Rutting Test for Asphalt Mix Design QC/QA. Journal of the Association of Asphalt Paving Technologists, 719-750.

Yin, F., Taylor, A. J., & Tran, N. (2020). Performance Testing for Quality Control and Acceptance of Balanced Mix Design. Auburn, AL: NCAT Report 20-02.

Yin, F., & West, R. C. (2021). Balanced mix design resource guide (No. IS-143).

Zhou, F., Steger, R., & Mogawer, W. (2021). Development of a coherent framework for balanced mix design and production quality control and quality acceptance. Construction and Building Materials, 287, 1230.

Contact Chen Chen (left), Adam Taylor (middle), or Nathan Moore (right) for more information about this research.