- Spring 2023

Searching for a Test to Evaluate Low-Temperature Thermal Cracking Potential

Most state agencies are embracing the idea of specifying asphalt mixtures using a balanced mix design (BMD) approach. A key decision in the process of implementing BMD is selecting appropriate tests to assess resistance to the primary asphalt distresses encountered by a particular highway agency. Low-temperature thermal cracking is a common distress in regions that experience rapid drops in temperature.

In 2014-2015, MnROAD and NCAT developed an experiment to validate laboratory asphalt mixture cracking tests known as the Cracking Group Experiment. Two complimentary experiments were conducted: an experiment to validate tests for top-down cracking and an experiment to validate tests for low-temperature thermal cracking (LTC) of asphalt mixtures. The experiment to validate top-down cracking was built on the NCAT Test Track in 2015, and the experiment for LTC was built at MnROAD in 2016. The top-down cracking experiment results were published in NCAT Report 21-03 and summarized in the fall 2021 NCAT newsletter.

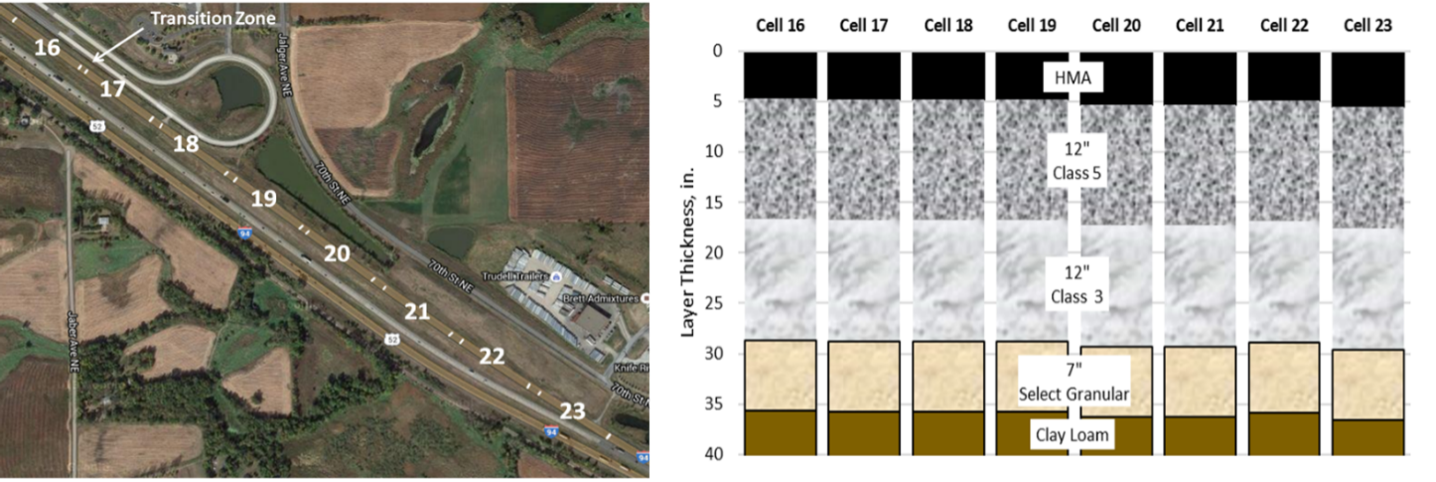

The MnROAD Cracking Group experiment was sponsored by DOTs in Illinois, Michigan, Minnesota, New York, and Wisconsin. The experiment included eight test sections (cells) constructed on MnROAD cells 16-23. Each cell included two 12-foot travel lanes with a 10-foot outside shoulder and a 4-foot inside. Figure 1 shows the cell locations on the MnROAD mainline and their structural layout. Each cell had the same pavement structure but different surface mixtures designed with various recycled materials contents and binder grades to provide a wide range of expected thermal cracking performance. Field performance of the cells was monitored for 5 ½ years.

Figure 1. Figure 1. (a) Aerial view of MnROAD Cracking Sections on MnROAD Mainline, and (b) Section Pavement System Structural Designs.

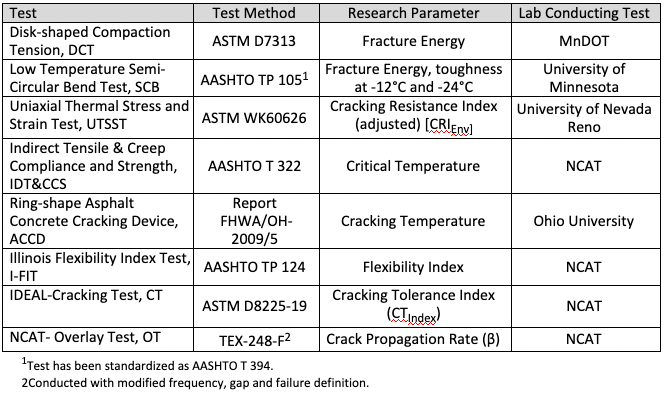

Eight cracking tests were evaluated in the testing plan as shown in Table 1. Five of the tests are conducted at low temperatures and are considered to be thermal cracking tests, and three of the tests are conducted at intermediate temperatures as general cracking tests, but were included in the experiment to determine if meaningful correlations exist with the field performance of the cells.

Table 1. MnROAD Cracking Group Test Evaluated.

The cracking tests were conducted on plant mixes sampled during construction. For each mix, two sets of plant-mixed, laboratory-compacted samples were prepared. The first set was compacted after samples were reheated to the compaction temperature. The second set of samples were prepared using reheated mix that was then critically aged for six hours at 135°C prior to compaction. The term “critical aging” was introduced by NCAT to simulate four to five years of in-service aging of surface asphalt layers. For the UTSST, the second set of samples were prepared with reheated mix then the compacted samples were long-term oven aged at 85°C for five days per AASHTO R30. Low-temperature SCB tests were only conducted on reheated samples. Correlations were made using distress survey results from 2020, 2021, and 2022 (3 ½, 4 ½, and 5 ½ years of service) to the eight lab test results for both aging conditions.

Based on the results of the MnROAD low-temperature cracking study, the following findings are provided:

Although the experiment was intended to yield a wide range of thermal cracking performance, the actual range was tighter than expected due to the properties of the asphalt mixture components. For example, the RAP and RAS used in the mixtures were relatively soft so the range of recovered binder grades from the experimental mixtures was narrow. Overall, the narrow range of material properties caused many of the mixtures to have similar thermal cracking field results, which diminished the reliability of the lab to field relationships.

- Disk-shaped Compact Tension Test (DCT): The fracture energy results generally had good repeatability with within-lab coefficients of variation (COVs) between 10 to 16%. The correlation between the lab results and field performance appeared to improve with mixture aging. Moderate to strong correlations with thermal cracking were found with the critically aged results, with DCT showing the strongest correlation with thermal cracking after 5 ½ years of service (R²=0.85).

- Low-Temperature Semi-Circular Bend Test (SCB): The fracture energy results had within-lab COVs between 7 and 37%; fracture toughness results had COVs of 5 to 17%. For tests conducted at -24°C, fracture energy and toughness results had strong correlations to field performance with R² values of 0.79 and 0.89, respectively.

- Uniaxial Thermal Stress and Strain Test (UTSST): The CRIEnv parameter had low correlations to field performance with R² values of 0.33 and 0.20 for the results of reheated and aged samples, respectively.

- Indirect Tensile Creep Compliance and Strength Test (IDT-CC&S): For tests conducted on reheated mixtures, the critical temperature did not correlate to field performance, while the correlation for test results using critically aged mixtures had a fair correlation (R²=0.60).

- Asphalt Concrete Cracking Device (ACCD): Results from this test did not correlate well with the field performance of the sections. The critical low temperature results indicated poor correlations to the field performance with R² values of 0.28 and 0.21 for results of reheated and critically aged samples, respectively.

- IDEAL Cracking Test (IDEAL-CT): The within-lab COVs of CTIndex ranged from 5 to 28%. The IDEAL-CT results for reheated mixtures had a poor to moderate correlation with field performance. For critically aged mixtures, CTIndex had moderate correlations with thermal cracking at 3 ½ and 4 ½ years of service, but the correlation was much stronger at 5 ½ years (R²=0.84).

- Illinois Flexibility Index Test (I-FIT): Within-lab COVs of the Flexibility Index (FI) ranged from 16 to 63%. For reheated mixtures, FI had a poor correlation to field performance. For critically aged mixtures, FI had weak correlations with thermal cracking at 3 ½ and 4 ½ years of service, but the correlation improved (R²=0.70) for the 5 ½ year field performance data.

- NCAT Overlay Test (OT): The within-lab COVs of the β parameter ranged from 7 to 73%. For reheated mixtures, the β parameter had a strong correlation to low temperature cracking, with the highest correlation at 3 ½ years of services (R²=0.96). For critically aged mixtures, the strength of the correlations between the β parameter and field data was lower but still moderate to strong with the highest correlations with field performance at 5 ½ years of service (R²=0.85).

Overall, the DCT and SCB tests had the best correlations with field performance. The IDEAL-CT test also had good correlations to thermal cracking for critically aged mixtures. Although the OT test results had the highest R², its high variability diminishes its utility as an indicator of thermal cracking.

Contact Carolina Rodezno for more information about this research.