- Spring 2023

Benchmarking Cracking Resistance of Alabama Mixtures

In Alabama, Superpave asphalt mixtures are designed and accepted for payment based on volumetric properties and tensile strength ratio (TSR) conducted periodically during production. While these specifications have largely eliminated rutting in the state, there are concerns that they are not adequate for assessing the cracking susceptibility of asphalt mixtures that contain reclaimed asphalt pavement (RAP) and recycled asphalt shingles (RAS).

To address these concerns, the Alabama Department of Transportation (ALDOT) plans to implement the Indirect Tensile Asphalt Cracking Test (IDEAL-CT) described in ALDOT Test Procedure 459 (ALDOT-459), which is very similar to the method in ASTM D8225-19. Several studies have reported that the CTIndex parameter correlates well with cracking data from test sections (Zhou et al. 2017, West et al. 2019). A higher CTIndex indicates better resistance to cracking.

To assist ALDOT in implementing the cracking test, a benchmarking study was completed on asphalt mixtures currently used in Alabama. The CTindex results of the Alabama mixtures were assessed against the CTIndex threshold recommended from the NCAT Test Track Cracking Group experiment (West et al. 2019).

Experimental Plan

The benchmarking effort was conducted on both laboratory-prepared and plant-produced mixtures. The laboratory mixtures were tested by the ALDOT Bureau of Materials and Test during mix design approval from 2020 to 2022. In addition, plant-produced mixtures were sampled throughout the state during the 2019 to 2022 construction seasons and tested by NCAT.

A total of 456 laboratory mixtures were tested, representing a wide range of mixture types and components (i.e., binder content, binder type, recycled materials content, aggregate type, maximum aggregate size (MAS), and additives). Binder contents ranged from 4.2% to 6.8%, and RAP contents were up to 35%. All laboratory mixes were prepared by the contactor submitting the mix design for approval. Each contractor was responsible for short-term conditioning the mix at 135℃ for four hours per AASHTO R30-2002 before compacting to a target height of 62 ± 1 mm with 7 ± 0.5 percent air voids for the cracking test.

In addition to lab mixtures, 38 plant mixtures were tested. As with the lab mixtures, the plant mixtures included a wide range of mixture components and mix types. Testing was conducted on mixtures subjected to two aging conditions: (1) reheated (RH) plant mix for all mixtures and (2) critically aging (CA) to simulate the impact of aging of surface mixes. Critical aging was conducted on 17 SMA and Superpave surface mixtures. The CA protocol involves conditioning the loose mix sample for 8 hours at 135°C before compaction, simulating approximately 4 to 5 years of field aging in Alabama (Chen et al. 2018).

Benchmarking Cracking Resistance

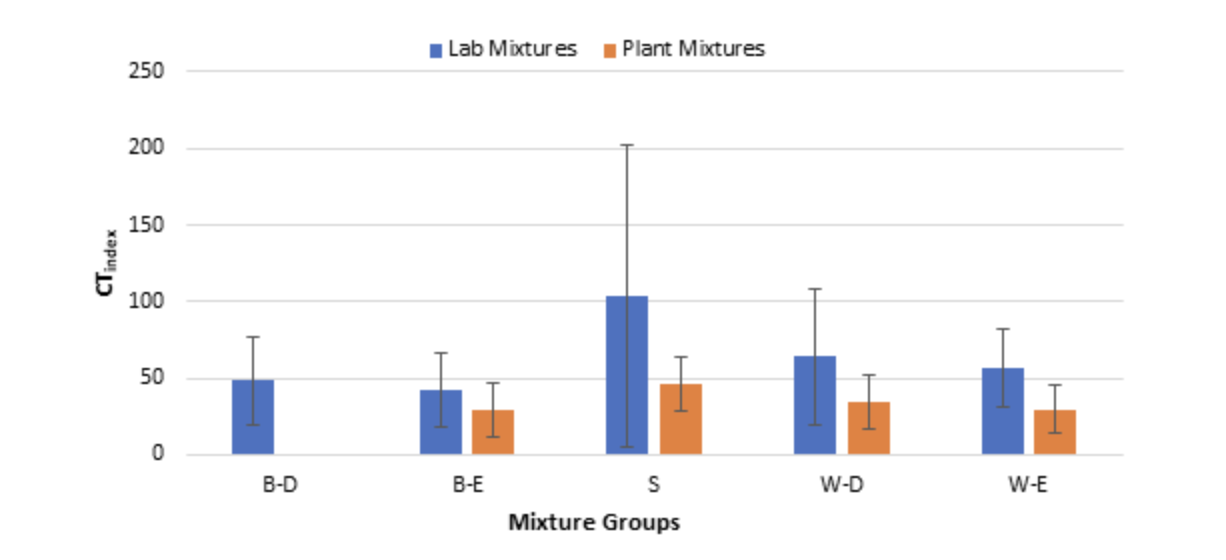

Figure 1 compares the average CTIndex of the lab and RH plant mixtures, with error bars indicating one standard deviation (s) above and below the mean (±1s encompasses 68% of the data distribution). The results are grouped by:

Mix type: Base/Binder(B), SMA (S), and Wearing Surface (W)

Traffic level: up to 10M ESALs (D) and up to 30M ESALs (E).

The CTIndex values were highest for the SMA mixtures, followed by the Wearing Surface and Binder/Base mixtures. CTIndex values generally increased with total asphalt content (AC) but decreased with increasing MAS and RAP content. Notably, Figure 1 illustrates a large range in the cracking resistance of the mixtures within each grouping, as indicated by the size of the error bars compared to the respective average values. These results suggest that relying solely on volumetric properties in the current mix design and acceptance fail to capture the large differences in the cracking resistance of these mixtures.

Figure 1: Comparison of Average CTIndex Between Lab and RH Plant Mixtures.

Another observation from Figure 1 is that the average CTIndex results of short-term aged, lab mixtures were about twice as high as the CTIndex of the RH plant mixtures. The largest difference between the lab and plant mixtures was for the SMA mixtures. The differences in CTIndex between lab and plant mixtures may be attributed to variations in:

- differences in component materials (e.g. binder source) between the design and production mixtures,

- aging levels between lab mixing and plant production, or

- the reheating process for the plant mixtures.

These results suggest that relying solely on lab mixtures during mix design approval is inadequate, as they do not accurately reflect the cracking resistance of plant mixtures in this study. Therefore, it is essential to test the plant mixtures, which are more representative of the compacted pavement, to ensure optimal performance.

Comparing with Thresholds Observed in Test Track Cracking Group Experiment

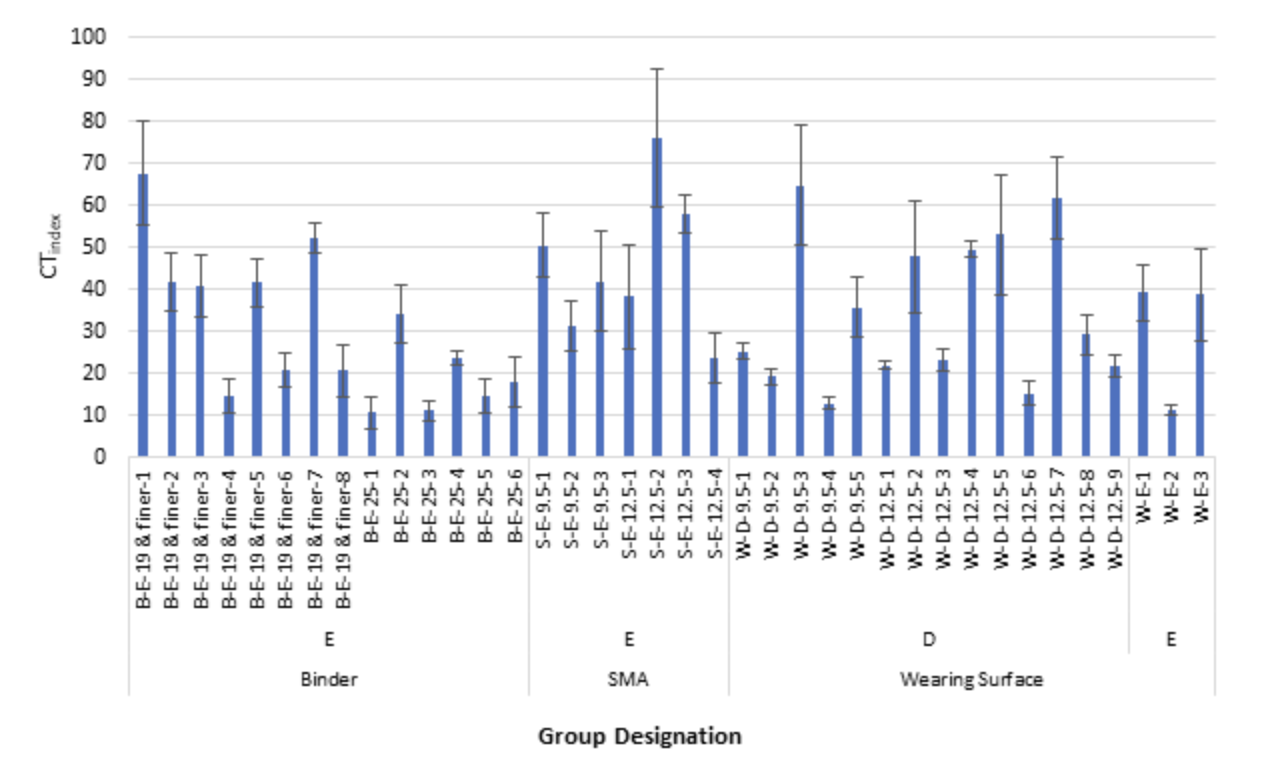

Results from the NCAT Test Track Cracking Group (CG) experiment showed that short-term aged mixtures with CTIndex above 30 and critically-aged mixtures with CTIndex above 15 had no cracking. (West et al. 2019). These values were used in this study as CTindex thresholds to assess the benchmarking databases of plant mixtures.

As shown in Figure 2, approximately half of the plant mixtures collected from Alabama contractors did not meet the reheated CTIndex threshold of 30. Only one of the seven RH SMA mixtures did not meet this threshold, but more than half of the RH Wearing Surface and Binder/Base mixtures had CTIndex values below the threshold.

Figure 2: Comparing CTIndex of Reheated Plant Mixes with the CG Experiment CTIndex Threshold.

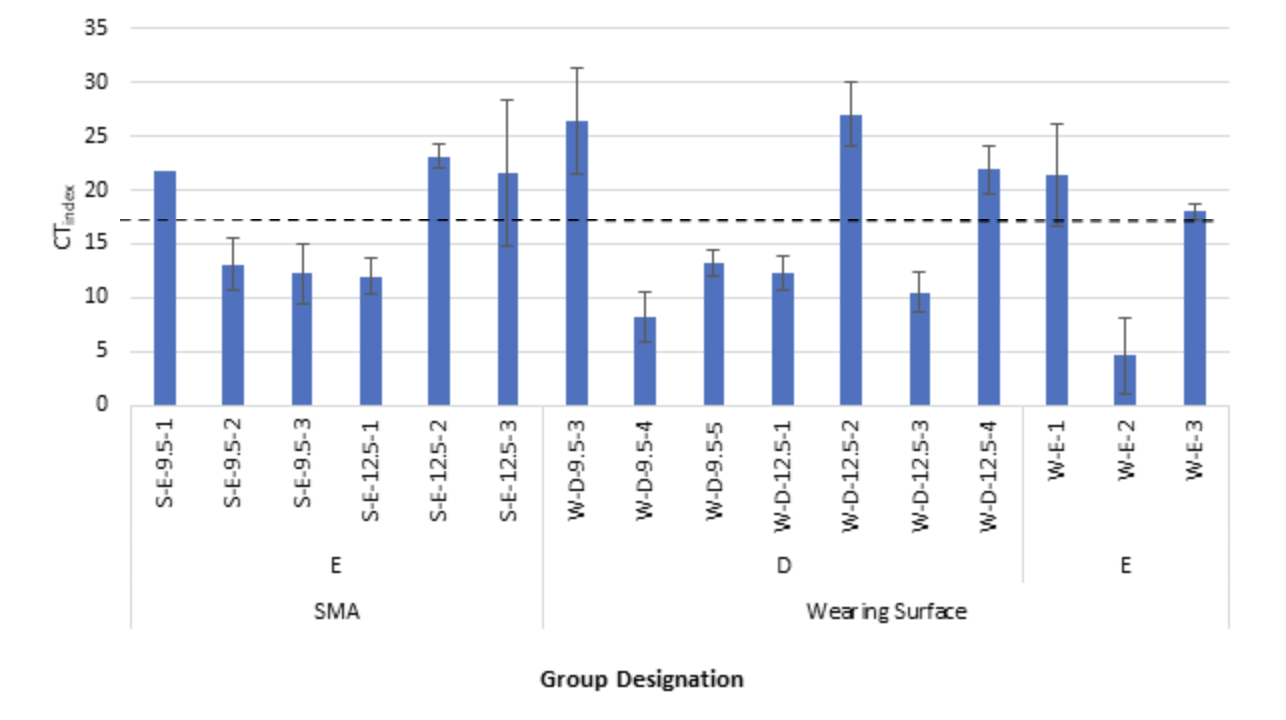

After critical aging, half of the SMA and half of the Wearing Surface mixtures did not meet the CTIndex threshold of 15, as shown in Figure 3. These results suggest a need to improve the mix designs and production processes for these mixtures. Further analysis is examining mix factors with mixtures in the database to determine the impacts of binder grade, effective asphalt content, aggregate types, and recycled materials contents.

Based on the results of the benchmarking experiment, ALDOT also plans to validate the CTIndex thresholds using field test sections on open access roadways with additional research to identify mix design strategies and additives that can help improve the cracking resistance of asphalt mixtures in Alabama.

References

Chen, C., Yin, F., Turner, P., West, R. C., & Tran, N. (2018). Selecting a laboratory loose mix aging protocol for the NCAT top-down cracking experiment. Transportation Research Record, 2672(28), 359-371.

West, R., Timm, D., Powell, B., Heitzman, M., Tran, N., Rodezno, C., ... & Vargas, A. (2019). Phase VI (2015–2017) NCAT test track findings (No. NCAT Report 18-04). Auburn University. National Center for Asphalt Technology.

Zhou, F., Im, S., Sun, L., & Scullion, T. (2017). Development of an IDEAL cracking test for asphalt mix design and QC/QA. Road Materials and Pavement Design, 18(sup4), 405-427.

Contact Nam Tran or Zane Hartzog for more information about this research.