- Spring 2021

Lessons Learned from the First Mixture Rejuvenator Evaluation on the Test Track

Several methods have been investigated to reduce potential adverse effects of reclaimed asphalt pavement (RAP) binder on the field performance of asphalt mixtures. One method is to use rejuvenators to restore rheological properties of oxidized asphalt binders in RAP mixtures. These rejuvenators can be petroleum-based or bio-based oils formulated to restore the balance of maltenes that were lost or transformed to asphaltenes in the oxidized RAP binder.

One of the bio-based rejuvenators commercially available is Delta S, which was developed by the Warner Babcock Institute for Green Chemistry and later commercialized by Collaborative Aggregates, LLC for use in recycled asphalt mixtures. This bio-based rejuvenator was used to produce an asphalt mixture with recycled materials placed in the surface layer of Section N7 on the NCAT Test Track, and the test section was trafficked for field performance evaluation from 2015 through 2021. Its performance was compared with that of Section N1, which was the control section for the Cracking Group experiment.

The two surface mixtures were designed to meet the volumetric requirements in AASHTO M323. The main difference between the two surface mixtures was that while the N1 surface mixture was designed with 20% RAP, the N7 surface mixture was designed with a higher recycled content and Delta S to counter the effect of the high recycled content on the mixture’s cracking resistance. The Hamburg Wheel Tracking Test (HWTT) and Illinois Flexibility Index Test (I-FIT) were conducted on short-term aged specimens to verify their similar rutting and cracking performance. The two mixtures were paved on the same pavement structures with 7 inches of asphalt concrete. The surface layer of N7 was originally built on August 6, 2015 using a 9.5 mm mixture containing 20% RAP and 5% post-consumer recycled asphalt shingles (RAS). Delta S was added to the virgin PG 67-22 binder at a dosage of 10% by weight of the recycled binders available in the RAP and RAS.

Truck trafficking of the sections began in the fall of 2015. Cracking on Section N7 was first observed in late January 2016 after 1.4 million equivalent axle loads (ESALs). Cores extracted from the section indicated that the cracks were caused by delamination between the surface and intermediate asphalt layers.

Section N7 was repaired by milling and repaving the same mixture with an increased tack rate to improve the interlayer bond strength between the surface and underlying layers on April 15, 2016. After just a few hours of fleet operations, a slippage failure was observed in the section.

A forensic evaluation of the surface mixture found that the delamination was not caused by a weak bond strength or insufficient tack coat, but in fact was due to reduced stiffness and tensile strength of the surface mixture. This evaluation included field cores and specimens prepared using (1) laboratory-prepared mixtures that were unaged, aged for two hours at 135oC, aged for four hours at 135oC and (2) reheated plant mix.

The surface mixture produced on April 15, 2016 had been laid and compacted without any silo storage, as it was produced and hauled to the Test Track (approximately 10 minutes away) for immediate paving. Because of the short haul, the interaction between Delta S (blended with the virgin binder) and the recycled binder, especially in the RAS, may not have been completed, leaving a higher proportion of Delta S in the virgin binder than originally intended. This caused a decrease in stiffness and tensile strength, leading to the shear failure in the surface mixture.

Section N7 was rebuilt by removing all asphalt layers and repaving from the aggregate base up on May 12, 2016. The redesigned surface layer for N7 contained 35% RAP (no RAS) and Delta S injected into the PG 67-22 binder supply line at a target rate of 5% by weight of RAP binder. To give the rejuvenator time to interact with the RAP binder, the mixture was held in a silo for two hours before being transported to the Test Track.

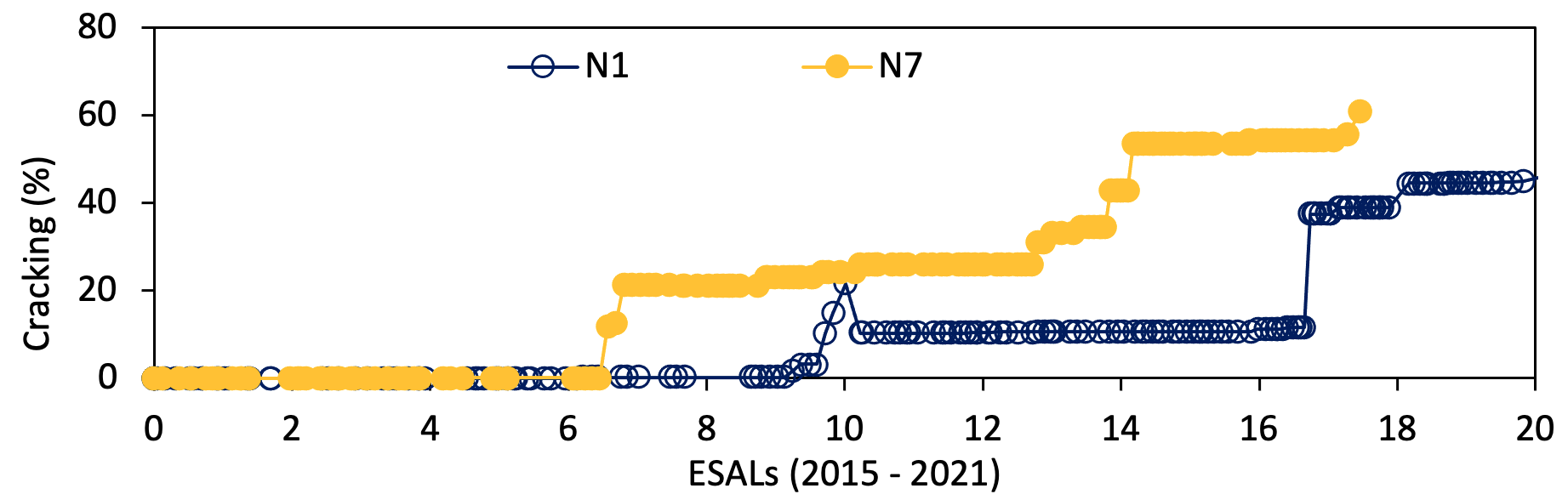

Figure 1 compares the field cracking performance of N1 and the May 2016 rebuild of N7. Section N1 had already carried approximately 2.5 million ESALs when N7 was rebuilt. Thus, approximately 17.5 and 20 million ESALs were applied to Sections N7 and N1, respectively, by January 2021.

Figure 1. Test Track Cracking Performance for Sections N1 and N7.

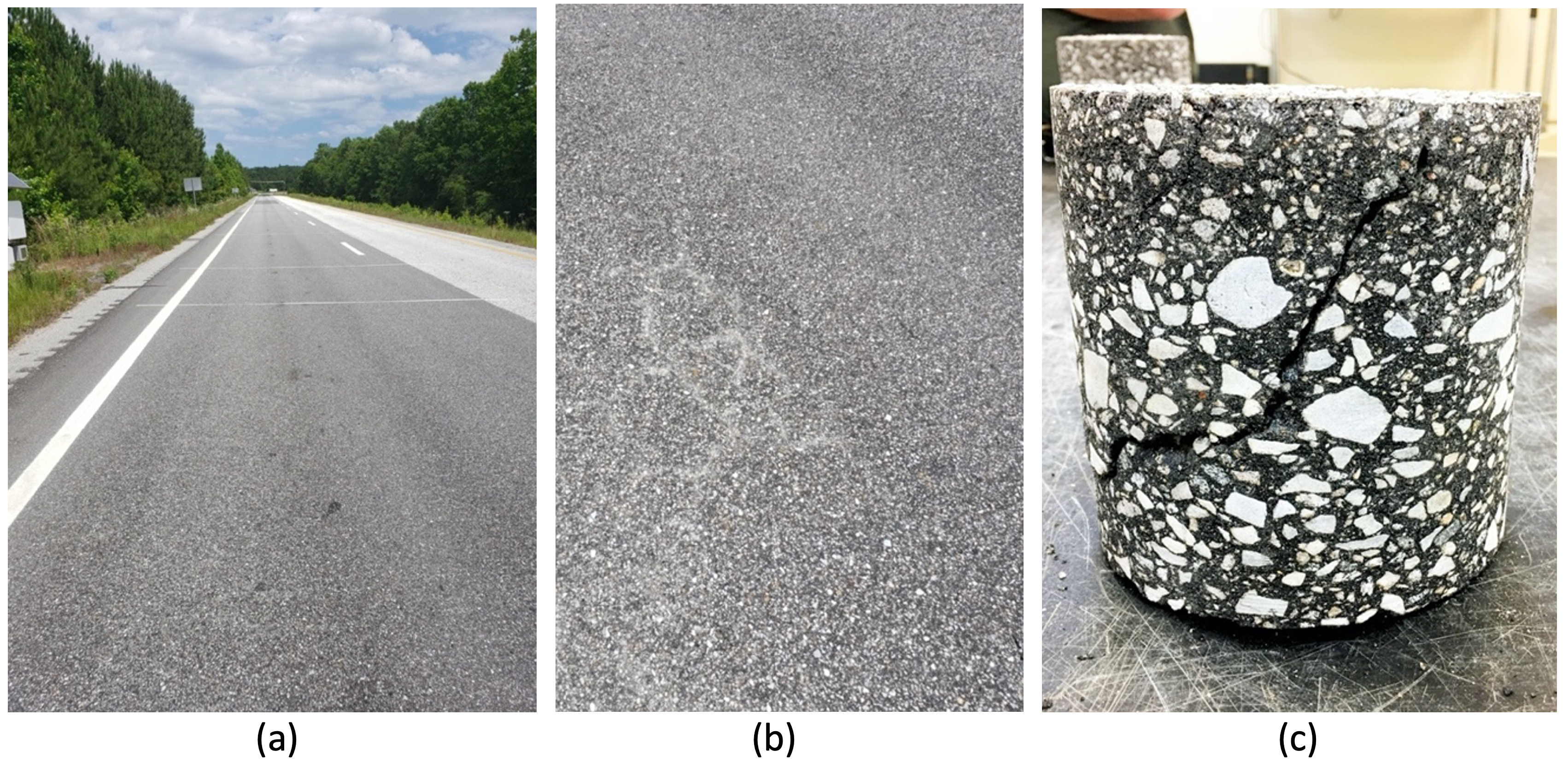

Cracking (only 0.1% of the lane area) was first noted in N7 on October 24, 2016 after 2.1 million ESALs. For N1, cracking (approximately 0.2% of the lane area) was first observed on March 6, 2017 after 6.2 million ESALs. Cracking in N7 jumped from 0.1% to 21.3% in October 2017 after approximately 6.6 million ESALs. For N1, cracking also increased significantly from 0.2% to 10.2% in October 2017 after 9.7 million ESALs. Cracking typically progresses quickly in spring (around March) and fall (around October) seasons at the Test Track. However, the cracks were very tight (less than 1 mm opening) near-surface cracks, as shown in Figure 2.

Cracking in N1 increased slightly from 10.3% at the beginning of the 2018 research cycle to 11.5% in March 2020 after 16.6 million ESALs. It then jumped to 37.4% the next month after 16.9 million ESALs. Cracking then gradually increased up to 45.8% at the end of the 2018 research cycle in February 2021. However, the severity of the N1 cracks remained very low.

Cracking in N7 did not increase again until March 2019 after 8.9 million ESALs when it increased slightly to 22.9%. Cracking increased gradually in 2019 up to 33.1% in December after approximately 12.7 million ESALs. No increase in cracking was observed between December 2019 and February 2020 after 13.3 million ESALs.

Figure 2. Close-up of Hairline Cracks in Sections N7 and N1.

The cracks observed in N7 in January 2020 were still low severity, as shown in Figure 3a. In some areas, the cracks became connected and fines could be seen along some of the connected cracks (Figure 3b). To further evaluate the cracks observed in N7, cores were extracted from the areas with the connected cracks. As shown in Figure 3c, these cracks were full depth and are believed to have initiated at the bottom of N7 and propagated to the surface.

Figure 3. (a) Section N7 as of January 8, 2020 (b) Closeup of Hairline Cracks in the Wheel Paths, (c) Field Core Confirming Bottom-Up Cracking.

After consulting with the sponsor, Delta Mist spray-on rejuvenator was applied to the cracked surface of N7 at a 0.08 GSY rate on February 21, 2020 (Figure 4) to evaluate if the spray-on rejuvenator could help extend the life of an asphalt pavement with bottom-up fatigue cracking. However, cracking progressed significantly the week after Delta Mist was applied. Cracking in N7 increased from 33.1% right before the Delta Mist application (13.3 million ESALs) to 53.4% in April 2020 after 14.2 million ESALs. The addition of Delta Mist presumably softened the distressed asphalt structure and accelerated the rate of bottom-up cracking (Figure 5).

Figure 4. Delta Mist Application on Section N7 in February 2020.

Figure 5. Section N7 Milled and Inlaid in May 2020 (a) Milled Surface Showing Bottom-Up Cracking (b) Area of Severe Bottom-Up Cracks.

In summary, lessons learned and key findings from the field evaluation of Delta S and Delta Mist rejuvenator products on the Test Track include the following:

- Delta S should not be used with southeastern post-consumer RAS without an adequate reaction time during production. Without an adequate reaction time with aged binders, Delta S may excessively soften the virgin binder, potentially leading to premature failures.

- - Short-term aged I-FIT results suggested similar cracking performance for the 35% RAP mix with Delta S and the control mix with 20% RAP. However, cracking appeared earlier and progressed slightly quicker for the 35% RAP mix with Delta S at the Test Track. The largest increase in cracking for both sections occurred in October 2017 (fall season) for the 2015 research cycle and in April 2020 (spring season) for the 2018 research cycle.

- - Connected cracks were observed in parts of Section N7. Cores from these areas indicated that these cracks were full-depth and believed to have initiated from the bottom layer and propagated to the top, affecting the cracking performance of the surface layer.

- - A spray-on rejuvenator is intended to slow the deterioration of surface distresses for pavements with sound structure. Thus, applying the Delta Mist spray-on rejuvenator to Section N7 when distresses had propagated from the bottom to the asphalt surface accelerated its failure.

For more information about this article, please contact Nam Tran.