- Spring 2021

Continuous Compaction Assessment Using a Density Profiling System

Construction quality assurance (QA) programs play a critical role for state highway agencies in ensuring that the materials and workmanship used on transportation projects is satisfactory and in reasonable conformance with their plans and specifications. Ideally, test results used in QA programs are available quickly enough to make adjustments in the production and/or construction operations to maintain the quality level desired.

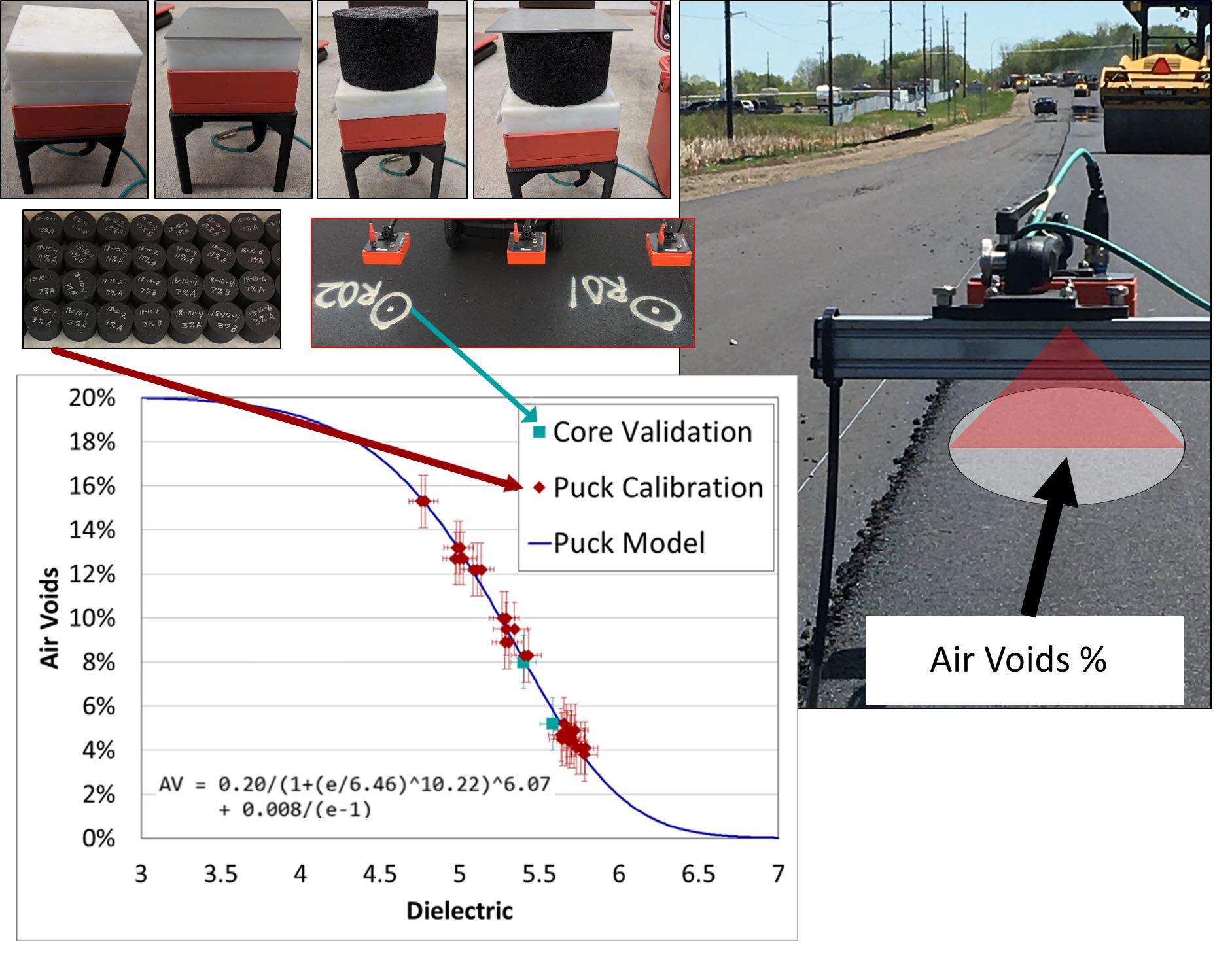

Ground-penetrating radar (GPR) is a non-destructive testing technology that has been used for years to determine pavement layer thicknesses. Several studies have recently shown that density profiling systems (DPS) that use GPR technology can also be used to evaluate the in-place density of pavement as well as uniformity of the compaction operations, as shown in Figure 1. A DPS unit, sometimes referred to as a rolling density meter, can identify the in-place relative density of pavements in near real-time by measuring the surface dielectric profile. Unlike coring and hand-held density gauge measurements taken from a few discrete locations, DPS units provide continuous measurements, resulting in nearly 100% coverage of the constructed layers.

Figure 1. Density Profiling System.

However, there are still some limitations regarding this new technology. Field cores are typically used to calibrate the measured dielectric constant to actual pavement density, although a coreless calibration solution is currently being evaluated. In addition, more information on the precision and bias is needed, as well as training — not only for how to conduct the test but also to interpret and use the results for quality control and acceptance.

The coreless calibration process is conducted by correlating dielectric measurements with asphalt specimens fabricated at a range of air void contents using a Superpave gyratory compactor (Figure 2). The resulting calibration curve is later validated with a few field cores taken from a test section. The DPS can then be used to take measurements throughout the rest of the paving for that layer and produce thousands of data points that would be equivalent to cores taken continuously at a 6-inch spacing.

Figure 2. Density-Dielectric Correlation Process.

NCAT is currently providing support and engineering services to the Minnesota Department of Transportation on their ongoing project, Continuous Asphalt Mixture Compaction Assessment using the DPS. The study involves further development of the DPS testing protocols and specifications. There are three primary tasks in the study. The first is to evaluate the effects of pavement layer thickness on DPS measurements, the second is to develop equipment and operator certification procedures and analysis methods and the third is to develop a precision and bias statement. Most of the work will be performed at NCAT’s main lab with field testing conducted during construction of the new test sections on the NCAT Test Track this summer. Results of this study are expected to be available by the end of 2021.

For more information about this article, please contact Fabricio Leiva.