- Spring 2021

Life Cycle Cost Analysis Residual Values

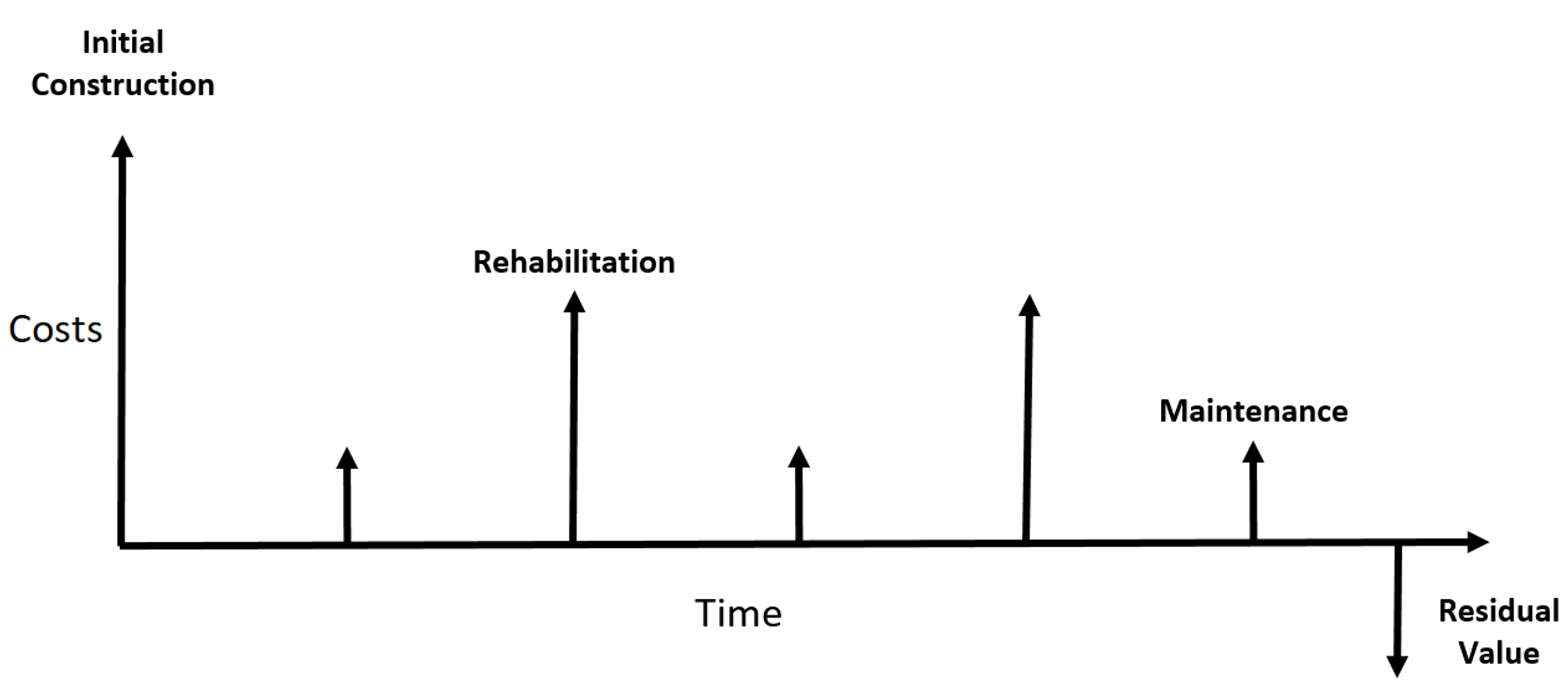

Highway agencies frequently use a life cycle cost analysis (LCCA) as a method to evaluate competing pavement design alternatives, primarily between asphalt and concrete pavements. An LCCA is a process that takes into consideration the expected costs over the life of each pavement alternative to identify which has the best long-term value. In addition to initial construction costs, an LCCA also considers future costs such as maintenance, rehabilitation and sometimes user costs, all of which are converted into present dollars (called net present value or cost). Any pavement value remaining at the end of the analysis period is called the residual value, which is discounted back to a present value as a credit or negative cost. A typical expenditure stream diagram for a project (excluding user costs for simplicity) is shown in Figure 1.

Figure 1. LCCA expenditure stream diagram.

However, before we get into the mechanics of this issue, let’s consider what actually happens to asphalt and concrete pavements when they reach terminal serviceability. Concrete pavements are either entirely removed and replaced with a new pavement, rubblized in-place and overlayed with asphalt, overlayed with concrete or overlayed with asphalt. The choice of these options typically considers their costs, the disruption to traffic for each option, the impacts to other infrastructure elements in the right of way due to roadway elevation change and the agency’s historical success or failures with these options. Another factor now being considered more often by some agencies is environmental impact. For asphalt pavements, rehabilitation options are most often a mill and fill resurfacing, a structural overlay if additional load carrying capacity is needed, and in rare cases when lower pavement layers are compromised, full-depth reclamation and recycling of the pavement structure.

While there are a number of inputs required when conducting an LCCA, this article focuses on determining the residual value of the pavement structure. A residual value for the pavement is determined at the end of the LCCA analysis period. Depending on the anticipated condition of the pavement alternative at that time, this value can either be the salvage value or the remaining service life (RSL) value.

If the pavement has no remaining service life at the end of the analysis period, a salvage value is typically assigned. This represents the potential value of reusing or recycling the materials that would be removed (reclaimed asphalt pavement, crushed concrete, etc.). History shows that asphalt is recycled much more than concrete. However, it’s important to note that salvage values can be challenging to estimate since they depend on unknown supply and demand conditions anywhere from 35 to 60 years in the future. Consequently, they tend to be estimated on the low side, which makes them almost negligible when they are discounted back to a present day value.

In cases where the expected service life of the pavement extends beyond the analysis period, a value for the remaining service life should be included in the LCCA. Historically, most published LCCA guidelines have only considered the remaining service life of the last rehabilitation that occurred prior to the end of the analysis period. This is determined as shown by the following equation and example:

For example, if the last activity or rehab occurs eight years prior to the end of the analysis period, and that rehab has an expected service life of 15 years and costs $200,000 per lane mile, the remaining service life would be seven years (15 – 8), and the RSL value would be:

![]()

This value would then be discounted back to time zero to determine its present value.

One shortcoming with this methodology is that the remaining service life value is only determined for the last rehabilitation activity and not the underlying layers. It is very rare to encounter a flexible pavement that requires complete reconstruction at the end of its service life. Unless the base or subgrade layers have failed, flexible pavements — composed of a combination of multiple asphalt layers, granular base and subgrade — are commonly rehabilitated multiple times by milling and replacing the upper asphalt layers or adding a structural asphalt overlay. In practice, this cycle of milling and resurfacing asphalt pavements typically continues indefinitely, so there is a significant real value for the lower pavement layers. For a more accurate LCCA, it is essential that the RSL value for all pavement layers be taken into consideration. This is especially true when an LCCA is being conducted to determine the economy of building a perpetual pavement.

A more comprehensive analysis is to determine the RSL value for the most recent resurfacing that occurred prior to the end of the analysis period and the RSL value for the underlying layers. Several alternative methods are described in NCAT Reports 19-03 and 20-05. One approach is to compare the historical structural capacity or structural number of asphalt pavements based on non-destructive testing such as the falling weight deflectometer (FWD) to determine how their structural capacity or structural number changes over time.

One recommended method of determining the RSL value of underlying layers is through the following equation:

Where:

𝐶𝑂𝐷 = cost of the underlying layers in the original design or prior maintenance or rehabilitation,

𝑆𝑁𝐸X = structural number of the underlying layers in the existing asphalt structure, and

𝑆𝑁𝑂𝐷 = structural number of the underlying layers in the original design or prior maintenance or rehabilitation structure.

In situations where the underlying granular base and/or subgrade of the asphalt alternative is different than the concrete alternative, the remaining service life value of those layers should also be determined. One option is to use non-destructive testing to determine how the structural characteristics of these layers typically change over time as described above.

If used properly, LCCAs can be an effective method for an agency to compare pavement alternatives. However, it is critical that all components be included in the analysis, including the appropriate residual value. If the life of the pavement alternative is expected to extend beyond the end of the analysis period, the remaining service life of both the last rehabilitation and the underlying layers must be included. In making pavement type decisions, it is also important to consider other factors that may be more challenging to include in an LCCA, especially factors that impact pavement types beyond the analysis period. An agency’s history of what happens to asphalt and concrete pavements when they reach terminal serviceability is an important lesson to recall.

For more information about this article, please contact Jim Musselman.