- Spring 2021

Thin Overlays for Pavement Preservation

Thin asphalt overlays are one of the most popular preservation treatments for asphalt and composite pavements. While the definition of what constitutes a “thin” overlay tends to vary among agencies, the term generally refers to surface mixes of 1.5 inches or less placed on a well prepared surface. Although thin overlays used for pavement preservation are not designed to provide additional strength to a pavement structure, this is a natural consequence in addition to other benefits including improving smoothness and friction, reducing tire-pavement noise and sealing the pavement from moisture at relatively low costs.

NCAT has been studying thin overlays as pavement preservation treatments since 2012, when the first test sections were placed on Lee Road 159 in Auburn, just a few miles away from NCAT’s main facility. At the time, eight 100-ft test sections were placed as ¾” thin overlays to quantifying their life-extending benefits. The thin overlay test sections included all-virgin mixes with unmodified and modified binders, a mix with 50% reclaimed asphalt pavement (RAP), a mix with 5% shingles, a gap-graded bonded wearing course and thin overlays on other preservation treatments.

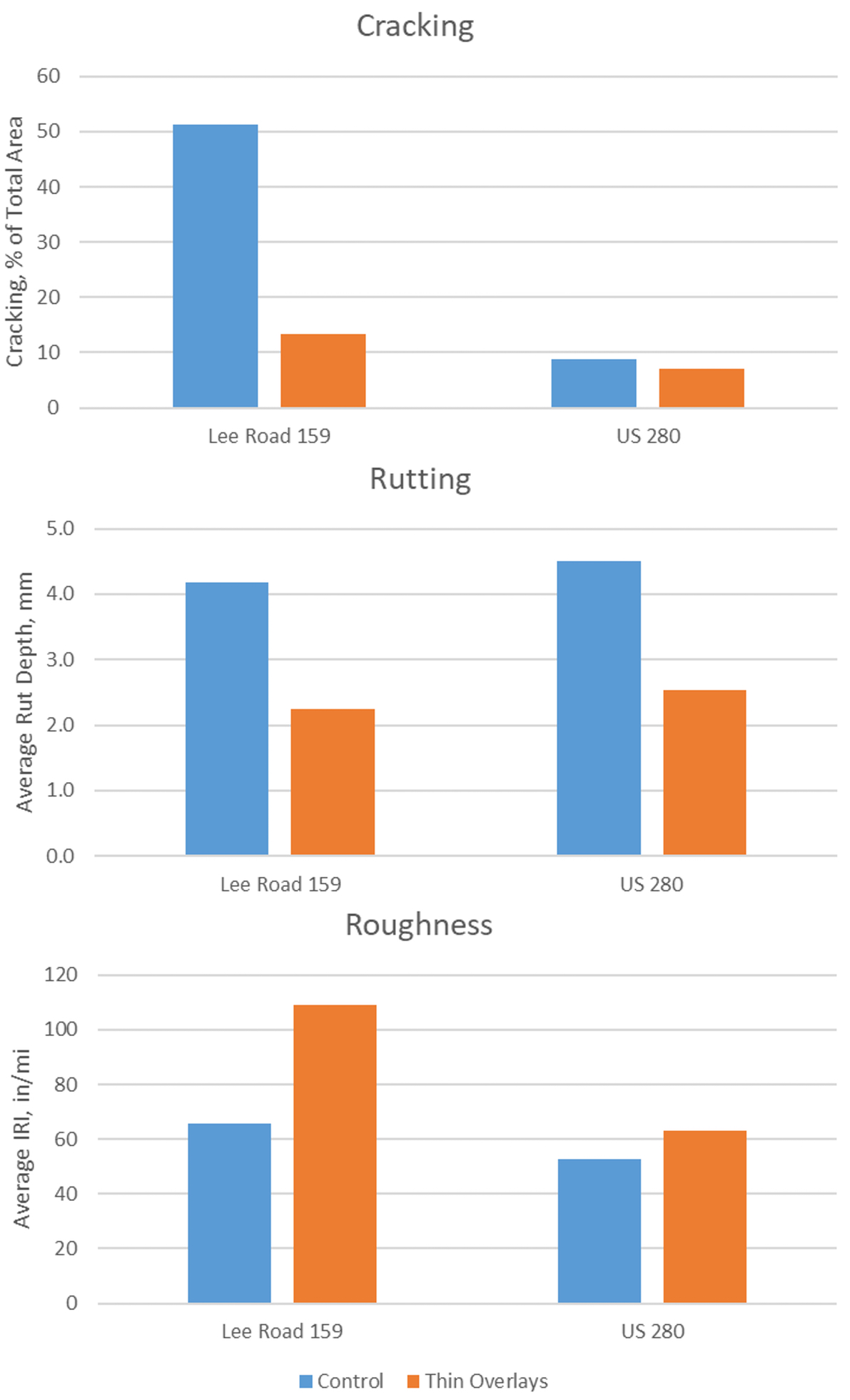

Nearly nine years later, all of the thin overlay treatments have been proven to slow down the rate of deterioration and extend the overall life of the pavement. Cracking, which was the main distress observed on this roadway prior to the treatments, was reduced up to 65% compared to the untreated sections. Average rut depths are under 5 mm and roughness remains stable over time. Deflection data collected with the falling weight deflectometer shows that although these are not structural overlays, they definitely help maintain a good pavement in sound structural condition for a longer period compared to untreated pavements.

Based on the promising preliminary data obtained from the Lee Road 159 experiment, the scope of the project was expanded to study the effect of traffic and climate on treatment performance. Additional sections were built on U.S. Route 280 in Alabama, as well as on County State Aid Highway 8 (CSAH-8) and U.S. Highway 169 in Mille Lacs County, Minnesota. These sections have been in service since 2015 and 2016, respectively.

Findings from the Lee Road 159 sections were instrumental in designing the layout of the subsequent testing sites. For example, the mixtures containing 50% RAP and 5% recycled asphalt shingles (RAS) included in the original test sections provided reasonable performance, as cracking eventually exceeded 20% of the total area after approximately seven years of service. To improve performance while still benefiting from the use of recycled materials, the later experiments used an early balanced mix design approach and incorporated both RAP and RAS in smaller proportions. These BMD thin overlays have shown improved cracking performance even when subjected to higher traffic volumes.

Another example is the use of thin overlays as the wearing course over cold recycled asphalt bases. In 2012, one of the very successful test sections consisted of a thin overlay over a 97% RAP foamed asphalt recycled base. Following the results from this low traffic volume test section, additional sections were constructed on more trafficked roadways to see if similar performance could be achieved. To date, these sections have withstood the higher traffic loads with little surface distress.

As NCAT’s pavement preservation research grew, other types of thin overlays were included in the study. Thin open-graded friction course overlays placed in high traffic test sections have maintained low levels of cracking, rutting and IRI. However, some functionalities associated with these mixtures (e.g. permeability and noise reduction) have decreased over the first five years of service. In addition, these sections were used to study different types of tack coats, all of which have provided adequate bond strength over time.

Finally, using thin overlays in combination with other treatments such as chip seals or scrub seals can increase the benefits of proactive pavement preservation. As with stand-alone applications, improved performance and greater life-extending benefits can be expected when the existing pavement is in good to fair condition. Continuing data collection and long-term performance monitoring will allow us to better quantify the benefits from all of the different thin overlay treatments as a function of existing condition, traffic and climate.

To date, all sections remain functional and exhibit less deterioration than the untreated surfaces, as seen in Figure 1. The higher roughness observed for the thin overlays are mainly related to the heavy braking conditions in the area where the thin overlays were placed.

Figure 1. Performance measurements for the average of the control and thin overlay sections.

While there are noticeable differences between treated and untreated sections, at this moment it is not possible to predict when the thin overlays will reach the end of their service life. The data collected in the upcoming years will be key to quantify the resulting life extension and assisting agencies in selecting the most cost-effective alternative to maintain their pavement networks.

For more information about this article, please contact Adriana Vargas.