|

|

|

Synopsis:

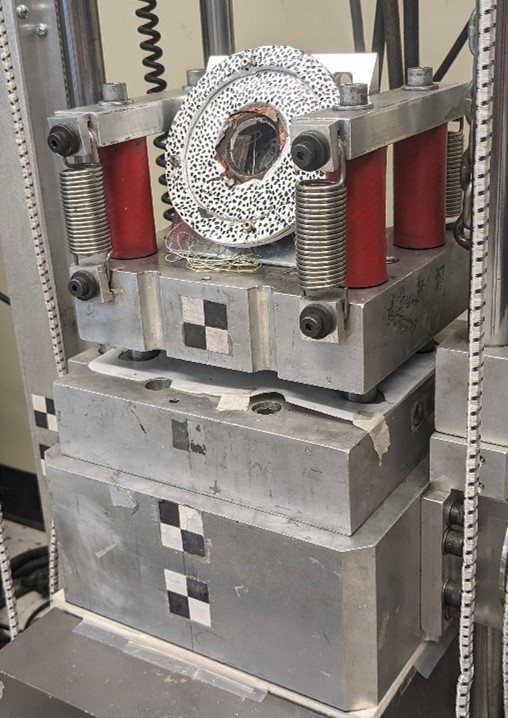

The reliability and durability of electronic components in aerospace and defense systems are critical due to the harsh operating environments and high-reliability expectations. In these sectors, electronics often face extreme conditions, including high g-forces of up to 100,000g, shock, vibration, and significant temperature variations. A Lansmont model 23 drop tower has been used in combination with a dual mass shock amplifier (DMSA) achieve higher acceleration levels and accelerometers are used to calibrate the drop tower. Electronic assemblies are frequently reinforced with potting materials, which offer mechanical strength, electrical insulation, and protection against shock, vibration, and corrosion to enhance reliability. However, the interface between the potting material and the PCB is a potential point of failure, particularly under high g shock loads, where delamination can occur, leading to moisture ingress and subsequent failure of solder interconnects.

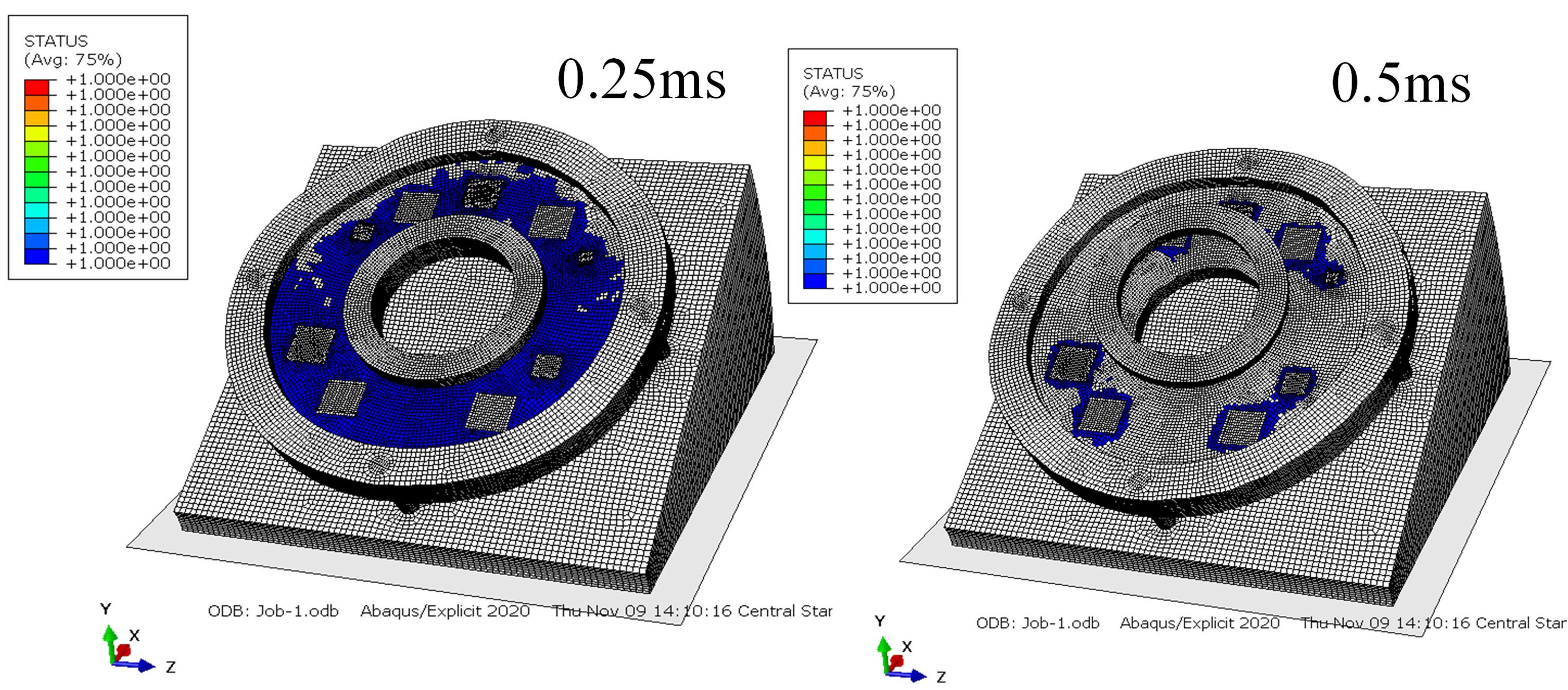

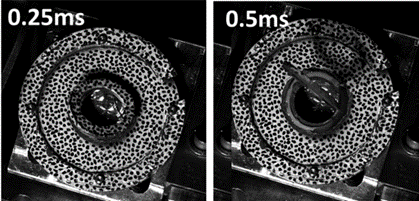

Our research has primarily focused on understanding the interfacial fracture behavior between potting materials and PCBs, with studies investigating the impact of isothermal aging and shock load angles on interfacial reliability. Further studies examine the effects of different drop angles and varying shock pulses on the reliability of potted electronic assemblies. Additionally, the incorporation of advanced techniques such as 3D Digital Image Correlation (DIC) enables precise measurement of strain and displacement during shock events, providing comprehensive data on the mechanical behavior of electronic components under extreme conditions. Predictive simulation models have been developed to predict damage of potted assemblies under high g shock loads.

Overall, understanding the high g shock survivability in electronic systems offers valuable insights for developing more reliable electronic assemblies for aerospace and defense applications.

Recent Related Publications:

- Lall, Pradeep, Aathi Raja Ram Pandurangan, and Ken Blecker. "Epoxy-PCB Interfacial Fracture Reliability under Three-Point and Four-Point Bend Loading After Sustained Elevated Temperature Exposure." Journal of Electronic Packaging (2024): 1-9.

- Lall, Pradeep, Aathi Raja Ram Pandurangan, and Ken Blecker. "Predictive Cohesive Zone Prediction of Delamination at Potting-PCB Interface Under Dynamic Loading and Sustained High-Temperature Exposure." 2023 22nd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm). IEEE, 2023.

- Lall, Pradeep, Aathi Raja Ram Pandurangan, and Ken Blecker. "Epoxy-PCB Interfacial Fracture Reliability under Three-Point and Four-Point Bend Loading After Sustained Elevated Temperature Exposure." Journal of Electronic Packaging (2024): 1-9.

- Lall, Pradeep, Aathi Raja Ram Pandurangan, and Ken Blecker. "Evolution of Interfacial Properties under Long Term Isothermal Aging of PCB/Potting Compound Interfacial Samples under Pure Mode-I Loading." 2022 21st IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm). IEEE, 2022.

- Lall, Pradeep, Aathi Raja Ram Pandurangan, and Ken Blecker. "Interfacial Fracture Toughness of PCB/Epoxy Interfaces Under Three Point and Four Point Loading with Sustained High Temperature Exposure." 2021 20th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm). IEEE, 2021.