Synopsis:

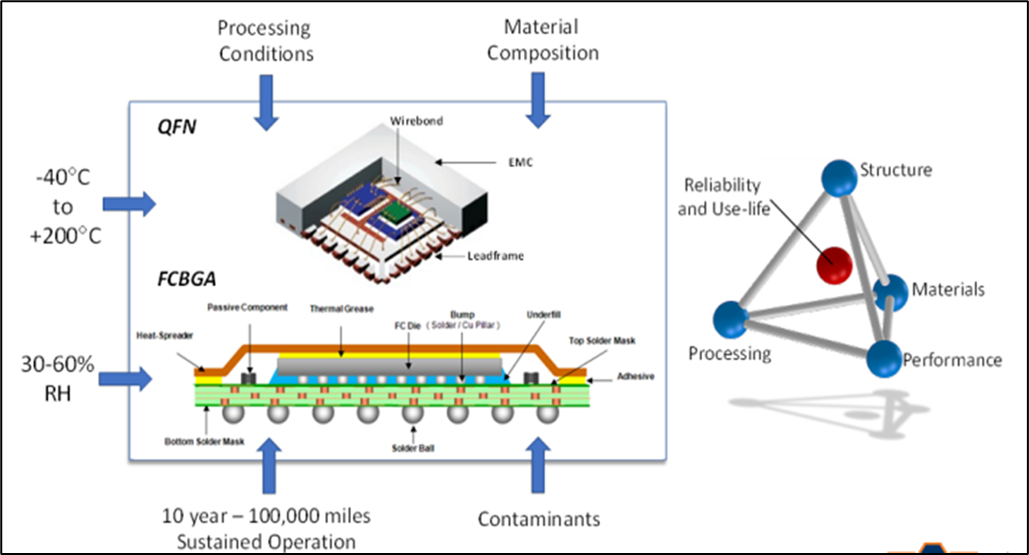

Electronics in harsh environment are often subjected to wide-temperature extremes, combined with high humidity and thermal cycling. Deformation and failure at these extreme environments are not well understood. The reliability performance of these fine pitch electronics are developed using various accelerated life testing models to provide leading indicators of material state.

Environment of Interest: single (High temperature Storage [200°C/1 Year]), sequential (150°C+85%R.H/85°C), cycling (-55°C to 150°C) thermos-mechanical loads, hygrothermal(8585%R.H/85°C) mechanical loads.

Representative Publications:

- Lall, P., Choudhury, P. and Pandurangan, A., 2022, May. Sustained High Temperature Fracture Toughness Evolution of Chip-UF and Substrate-UF Interfaces in FCBGAs for Automotive Applications. In 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC)(pp. 1577-1588). IEEE.

- Lall, P., Zhang, Y., Kasturi, M., Choudhury, P., Wu, H., Suhling, J. and Davis, E., 2021, June. Evolution of Viscoelastic Properties and Interface-Fracture Toughness Under Sustained High Temperature Operation Typical of Automotive Underhood for up to 1-year. In 2021 IEEE 71st Electronic Components and Technology Conference (ECTC)(pp. 971-982). IEEE.

- Lall, P. and Choudhury, P., 2022, May. Influence of Sustained High Temperature Exposure on the Interface Bond Strength between TIM-Copper Substrates. In 2022 21st IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm)(pp. 1-7). IEEE.

- Lall, P., Choudhury, P. and Pandurangan, A.R.R., 2023, October. Assessment of Propensity for Pad Cratering at the Board Resin-Glass Interface Under Assembly and Rework. In International Electronic Packaging Technical Conference and Exhibition(Vol. 87516, p. V001T08A010). American Society of Mechanical Engineers.

- Lall, P., Kasturi, M., Wu, H., Davis, E. and Suhling, J., 2020, October. Correlation of Microstructural Evolution with the Dynamic-Mechanical Viscoelastic Properties of Underfill Under Sustained High Temperature Operation. In International Electronic Packaging Technical Conference and Exhibition(Vol. 84041, p. V001T01A012). American Society of Mechanical Engineers.

- Lall, P., Pandurangan, A.R.R. and Blecker, K., 2022, May. Evolution of Interfacial Properties under Long Term Isothermal Aging of PCB/Potting Compound Interfacial Samples under Pure Mode-I Loading. In 2022 21st IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm)(pp. 1-8). IEEE.

- Lall, P., Zhang, Y. and Williamson, J., 2021, June. Degradation mechanisms of epoxy molding compound subjected to high temperature long term aging. In 2021 20th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm)(pp. 610-616). IEEE.

- Lall, P., Deshpande, S., Luo, Y., Bozack, M., Nguyen, L. and Murtuza, M., 2014, May. Degradation mechanisms in electronic mold compounds subjected to high temperature in neighborhood of 200° C. In 2014 IEEE 64th Electronic Components and Technology Conference (ECTC)(pp. 242-254). IEEE.

- Lall, P., Singh, N., Suhling, J.C., Strickland, M. and Blanche, J., 2005. Thermo-mechanical reliability tradeoffs for deployment of area array packages in harsh environments. IEEE Transactions on Components and Packaging Technologies, 28(3), pp.457-466.

- Lall, P., Shah, M., Drake, L., Moore, T. and Suhling, J., 2008. Thermo-mechanical reliability management models for area-array packages on Cu-core and no core assemblies. SMTA Journal, 21(3), pp.20-35.

- Lall, P., Islam, N., Suhling, J. and Darveaux, R., 2003, May. Model for BGA and CSP in automotive underhood environments. In Electronic components and technology conference, New Orleans, Louisiana(pp. 189-196).