- Fall 2020

Round Robin Study Assists With Balanced Mix Design Implementation

In 2018, NCAT initiated a round robin study for several mixture performance tests being considered for balanced mix design (BMD) implementation. A study overview was detailed in the fall 2019 NCAT newsletter. The study included the Hamburg Wheel Tracking Test (AASHTO T 324-19), the Illinois Flexibility Index Test or I-FIT (AASHTO TP 124-20), the Asphalt Pavement Analyzer or APA (AASHTO T 340-10), and the IDEAL Cracking Test or IDEAL-CT (ASTM 8225-19).

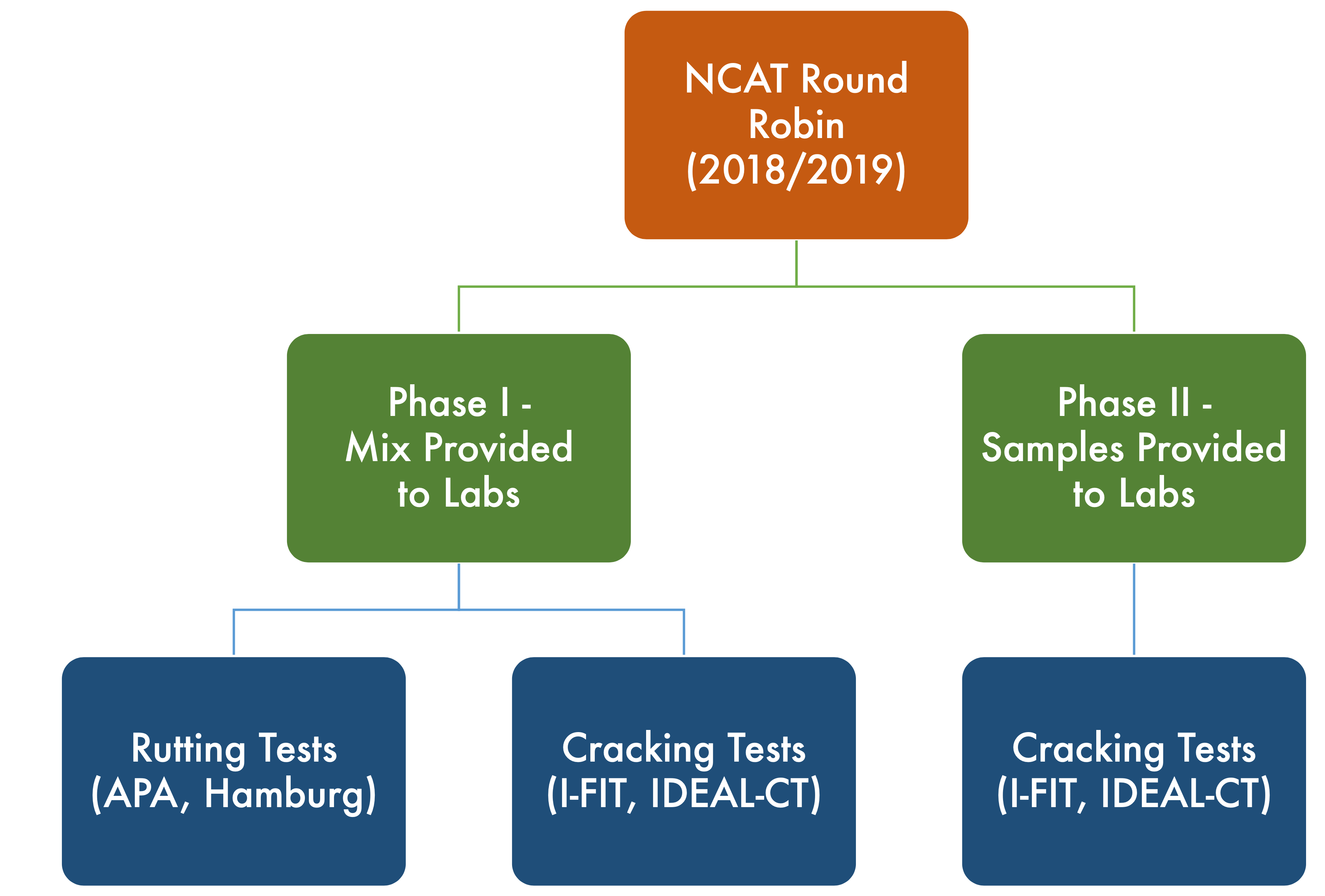

In Phase I, participating labs received a sufficient amount of plant-produced mix to fabricate specimens for their respective tests. The 9.5 mm NMAS mix with PG 64-22 binder and intermediate RAP content was designed using a BMD process. Each lab received detailed, test-specific instructions for specimen fabrication and testing along with a data file for reporting results. In Phase II (cracking tests only), prepared specimens of the same mixture from Phase I were shipped to each participating lab along with instructions for testing. These Phase II specimens were all fabricated by the same NCAT technician using best practices. A flow chart summarizing the testing plan is shown in figure 1.

Figure 1: NCAT Round Robin Study Scope

As of fall 2020, all tests for both phases of the study have been completed. Upon completion of each test and phase, a blind data summary report was sent to the participating labs. These reports did not include any laboratory names, but instead assigned each laboratory a number and revealed that number only to the participating lab submitting the data.

The data collected from the round robin are also being used for test variability analysis. ASTM E 691-19 Standard Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method provides a method for calculating both within-lab and between-lab coefficients of variation (COV). Some preliminary variability analysis was provided in the fall 2019 newsletter – however, this analysis has been updated using the more appropriate method from ASTM E 691-19. It should be noted that ASTM E 691-19 recommends between three and six materials (mixes in this case) be used to develop precision statements. This study included only one mix. However, the data can still be used to provide preliminary estimates of test variability.

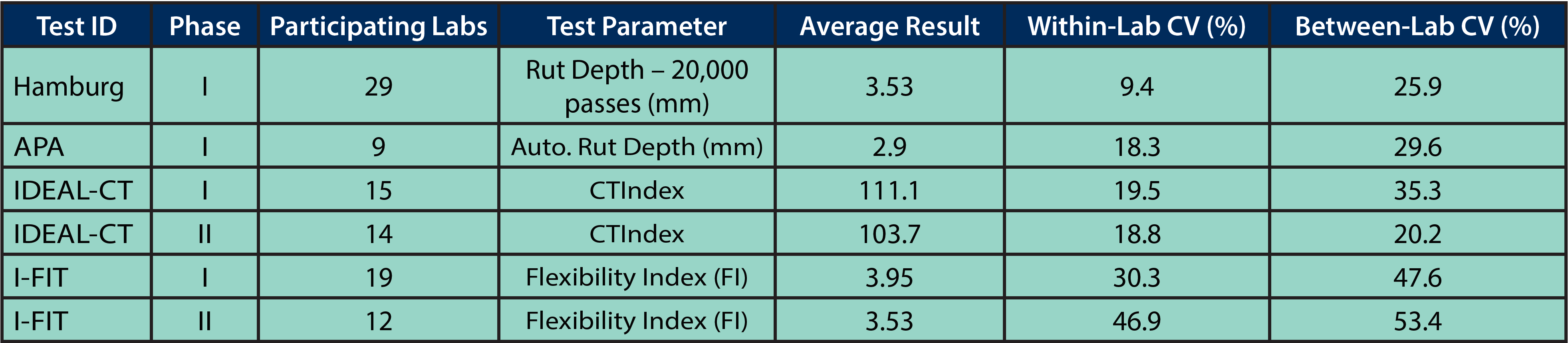

A summary of the preliminary ASTM E 691 within-lab and between-lab COV estimates for the NCAT Round Robin are shown in Table 1. Key observations from this data include the following:

-

- - Hamburg variability was assessed for rut depths at 20,000 wheel passes. Twenty-nine labs were included in the ASTM E 691 COV calculations. Three labs were removed as outliers for various issues. The Hamburg rut depths had a within-lab COV of less than 10 percent; between-lab COV was 25.9%, respectively. Except for one of the excluded labs, stripping was not observed. A mixture that exhibits stripping would likely have greater variability or necessitate an alternate method of analysis.

-

- - The APA had a within-lab COV of 18.3% and a between-lab COV of 29.6% for automated rut depth measurements. These COV values are higher than what was obtained for the Hamburg, albeit with much fewer labs (29 for Hamburg vs. 9 for APA).

-

- - For the IDEAL-CT CTIndex, the within-lab COV was similar for Phase I and Phase II at just below 20%. The within-lab variability was consistent with NCAT’s experience with the IDEAL-CT. However, the between-lab COV for CTIndex dropped from 35.3% to 20.2% from Phase I to Phase II. This highlights the importance of consistent sample fabrication on CTIndex results.

-

- - Variability for the I-FIT Flexibility Index (FI) was significantly higher than expected for both Phase I and Phase II of the study. AASHTO TP 124-20 recently added precision estimates based on I-FIT data from three separate round robin studies. These precision estimates have a within-lab COV of 27.1% (consistent with NCAT experience with the I-FIT) and a between-lab COV of 34.1% for FI. Variability estimates from the NCAT Round Robin were above these precision estimates, as shown in Table 1. For the single mixture used in the NCAT Round Robin, several labs reported replicates in the expected range (FI between 2 and 6) as well as multiple replicates with an FI below 1. This caused several labs to report very high COV values for both phases, which drove the high variability. The root cause is unknown but is believed to be a mix-specific issue.

Table 1: ASTM E691-19 Variability Estimates – NCAT Round Robin (Single Mixture)

A draft NCAT report summarizing the key findings from the study is currently being prepared. NCAT is also planning to conduct additional round robin studies to assist agencies and contractors with BMD implementation efforts. The future studies may include some of the rapid QC rutting tests that are gaining interest, such as the high temperature indirect tension test (HT-IDT). NCAT is also currently discussing providing the IDEAL-CT data to ASTM to assist in the development of a precision statement for the ASTM D 8225 IDEAL-CT standard.

For more information about this article, please contact Adam Taylor.