- Fall 2020

Implementation Spotlight: Highly Polymer Modified Binder Solves Rutting Issue in Alabama

The NCAT Test Track has conducted high-value research for agency and industry sponsors since the completion of the inaugural research cycle in 2000. Numerous findings that offer great value for agencies have been implemented from each of the previous seven research cycles. An excellent example of a new technology proven to be successful is highly polymer modified (HiMA) binder for specific cases where enhanced rutting and/or cracking performance is needed. As a result of Test Track research successes with both new pavement construction and pavement rehabilitation, the Alabama Department of Transportation (ALDOT) chose HiMA binder to solve a rutting problem on a high truck traffic, stop-and-go project on U.S. 231 after a high profile and costly rutting failure.

The NCAT Test Track has conducted high-value research for agency and industry sponsors since the completion of the inaugural research cycle in 2000. Numerous findings that offer great value for agencies have been implemented from each of the previous seven research cycles. An excellent example of a new technology proven to be successful is highly polymer modified (HiMA) binder for specific cases where enhanced rutting and/or cracking performance is needed. As a result of Test Track research successes with both new pavement construction and pavement rehabilitation, the Alabama Department of Transportation (ALDOT) chose HiMA binder to solve a rutting problem on a high truck traffic, stop-and-go project on U.S. 231 after a high profile and costly rutting failure.

The 4.9-mile project ran from the south city limits of Troy, Alabama to north of State Route 10 with several signalized intersections. This section of U.S. 231 is located within an area that provides multiple points of access from connecting roads and supports a high level of truck traffic. Rehabilitation was needed because of severe rutting in the relatively new pavement, which was worse at locations where trucks brake and accelerate. The failing pavement was a two layer stone matrix asphalt (SMA) mill/inlay, expected to be both durable and rut resistant; however, it was placed and later patched on this project with poor results.

The 10-inch asphalt pavement needed to be rehabilitated quickly in order to correct deep rutting that was steadily getting worse. ALDOT was skeptical about installing SMA again because it had already failed twice (including the original construction in 2008 and isolated patching later that same year). A solution was needed that would address the isolated structural inadequacies observed in forensics while at the same time provide long term rutting resistance in the binder layer. As seen in Figure 1, the binder layer appeared to be the primary source of the rutting when trenches were cut in 2008.

Figure 1. Rutting Observed in Binder SMA During Forensic Trenching

The distressed condition on this section of U.S. 231 was in several ways similar to a section on the Test Track that was subjected to an innovative rehabilitation alternative in the summer of 2010. This test section consisted of 10 inches of hot-mix asphalt (HMA) built on an imported soft subgrade to simulate in-service pavement construction in Oklahoma. The section exhibited extensive cracking at the end of the 10 million ESAL 2006 research cycle and failed again after it was rehabilitated with a 5-inch mill and inlay (the standard at the time in Oklahoma). Forensics conducted after the rehabilitation failure indicated that the pavement in this section had full depth cracking and rutting extending into the subgrade. Rut depths before the rehabilitation were as much as an inch and had returned up to a depth of 1½ inches by the time the conventional rehabilitation failed. Based on the excellent performance of a relatively thin HiMA modified test section in the previous research cycle, a 5¾-inch HiMA inlay was used to repair this failed test section and turn a full depth failure into a perpetual pavement.

Based on the success of the HiMA modified Superpave mixes on the Test Track, a similar approach was recommended to ALDOT. NCAT recommended that the badly rutted pavement on the US 231 project be milled to a minimum depth of 3.8 inches (the depth below which no rutting was noted when forensics were conducted in the fall of 2008) and inlaid with dense-graded HiMA Superpave mixes. ALDOT chose to mill the project 4 inches and replace it with a 2½-inch thick HiMA Superpave binder mix and a 1½-inch thick conventional polymer modified Superpave surface. In this manner, use of the costly HiMA binder was targeted in the higher shear binder layer where rutting had been forensically observed. Work was completed at night in the summer of 2012.

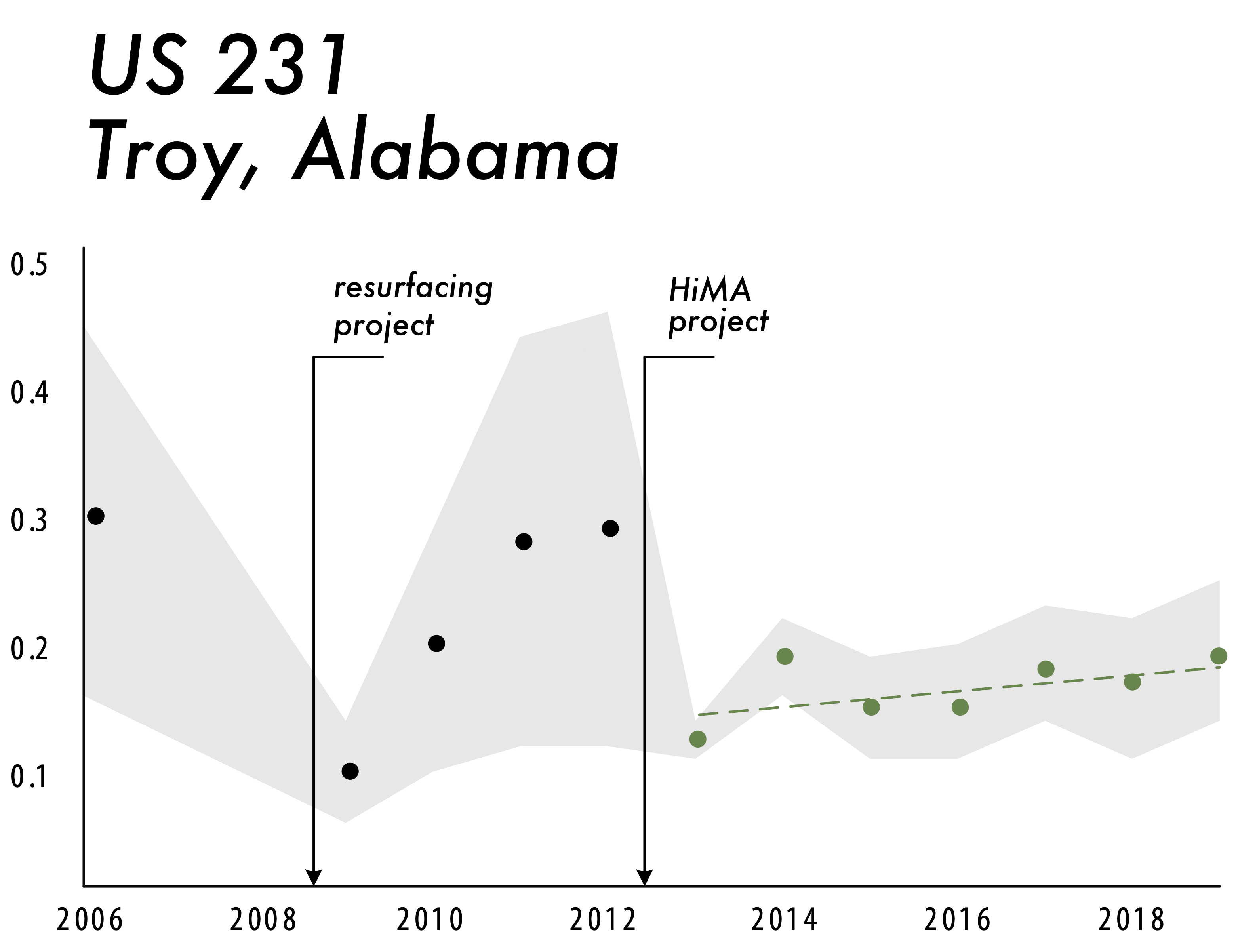

Rutting performance data from ALDOT’s Pavement Management Division is shown in Figure 2. High average rut depths were measured before and after the 2008 SMA inlay. Standard deviations are also high in Figure 2 prior to 2012 because the rut depths in intersections were so much worse than the rest of the project. Since the 2012 HiMA repair, average rut depths as well as standard deviations have been significantly reduced.

Figure 2. Average Rutting by Year (Bands Show ±1 Standard Deviation)

ALDOT is pleased with the performance of the HiMA mixes on this project and has since used it in other parts of the state to address specific rutting and/or cracking problems and to increase structural capacity where it is not possible to increase thickness due to grade limitations such as at bridges and sections with curbs and gutters. Because the need for HiMA binder is greatest on roadways that exhibited rapid failures in the past, ALDOT minimized the risk of implementation by relying on the proven performance of HiMA from the NCAT Test Track.

For more information on this study, please contact Buzz Powell (left). For more information on the data, please contact Frank Bell (right).