- Spring 2020

How Effective is Crack Sealing?

Treatment of a Pavement Preservation Group Study test section on Lee Road 159.

Crack sealing and filling can be cost-effective treatments when applied while the pavement is still in a state of good repair. These treatments consist of applying a highly elastic material into pavement cracks to prevent or reduce the intrusion of water and incompressible materials. The benefits of crack sealing include decreasing further crack deterioration, protecting the pavement structure from moisture damage, and ultimately extending the pavement life. Although the expected life extension is typically reported to be between two to five years, the benefit obtained depends on several variables such as traffic, climate, and the condition of the pavement at the time of treatment.

Answering the question of how much life-extending benefit can be gained from crack sealing–and other preservation treatments–is the main objective of the Pavement Preservation Group Study being conducted as part of the NCAT/MnROAD partnership. Thanks to the construction of full-scale test sections and periodic monitoring of pavement condition data, the study provides an ideal platform to quantify the benefits of preservation under different conditions.

The results discussed in this article are from test sections on Lee Road 159, a two-lane county road near NCAT that represents the low-traffic volume, warm climate portion of the research. Lee Road 159 has the oldest test sections in the study, which are now approaching eight years in service. A unique characteristic of this site is that it provides dead end access to a quarry and an asphalt plant, resulting in a high percentage of traffic with heavy loads. Although both lanes are subjected to the same traffic volume, traffic loads vary significantly as trucks travel unloaded in the inbound direction (to the quarry and asphalt plant) and exit loaded in the outbound direction.

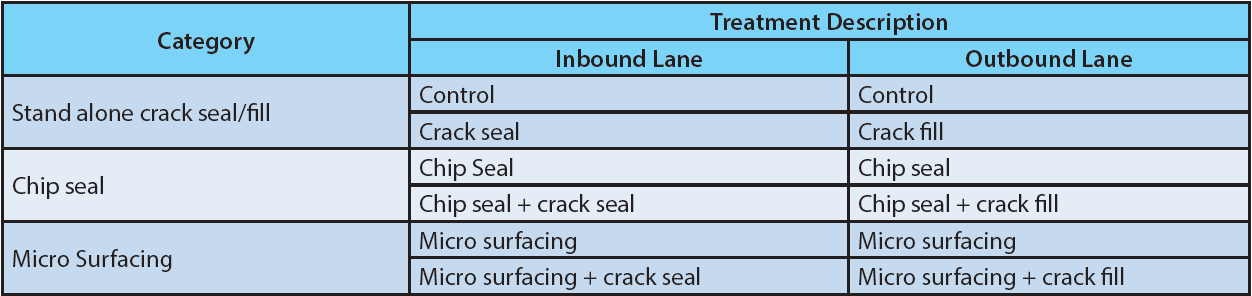

A subset of six test sections was selected to reflect potential differences in performance exhibited by pavements with and without crack sealing applied as a preservation treatment. The sections were divided into three categories, as shown in Table 1, to allow direct comparisons among pairs of treatments where the only difference in each pair is the application of crack filling or sealing. It should be noted that crack treatment varied by direction; cracks in the inbound lane were routed and sealed, while cracks in the outbound direction were filled using an overband method.

Table 1. Pavement Preservation Group Study test sections

Each 100-foot long test section was further subdivided into 5 by 10 foot subsections used to quantify the life-extending benefit of the pavement preservation treatments as a function of initial condition. Subsections were classified as “good”, “fair”, or “poor” depending on the pretreatment percentage of area cracked, with “good” condition being less than 5%, “fair” between 5 and 20%, and “poor” condition over 20%. These category ranges were selected to be consistent with the performance criteria established by the Federal Highway Administration to assess pavement condition as part of the National Highway Performance Program.

The long-term nature of this study is challenging since the primary variable of interest is the time to failure (in this case, failure being considered as reaching the “poor” category). Even after nearly eight years of service, some of the subsections have not reached failure. Fortunately, survival analysis is a statistical method that helps us overcome this obstacle because it allows the use of censored data (i.e. data in which the observed value is only partially known).

Survival analysis was performed on the Lee Road 159 data to generate survival curves, which show the survival probability over time. An analysis period of ten years was selected and the curves were used to compare each pair of treatments and calculate the life-extending benefit resulting from the crack sealing or filling treatment. While any survival rate can be used depending on the desired level of reliability, the median time to failure (MTTF) is typically used for this type of analysis. As shown in Figure 1, the life-extending benefit is calculated as the difference in MTTF between sealed and unsealed sections.

Figure 1. Life-extending benefit calculation

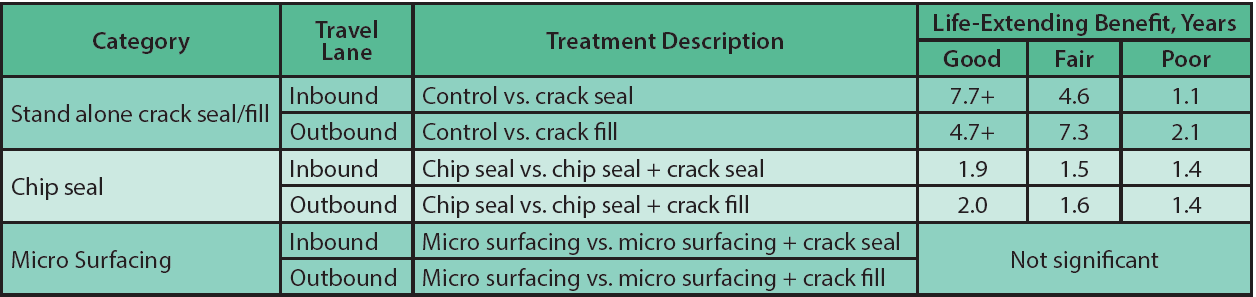

The results for each treatment pair as a function of pretreatment condition category are shown in Table 2. The results are also given by travel lane, which relates to both traffic loads and crack treatment. As expected, the MTTF benefit obtained from crack sealing depends on the condition of the pavement prior to treatment application and was higher for pavements treated while in “good” condition. When used as a stand-alone treatment on a pavement in “good” condition, the life-extending benefit could not be calculated for the selected analysis period because the sealed sections are not expected to reach the median time to failure within 10 years; however, the MTFF is expected to exceed 7.7 years for the crack sealing treatment and 4.7 years for crack filling treatment. In this case, test sections in the outbound lane had better results despite the increased traffic loads, which may be an indication that crack filling was more effective than crack sealing.

Table 2. Life-extending benefit as a function of pretreatment condition

If crack sealing or filling is used in combination with a chip seal, the life-extending benefit was similar in both travel lanes regardless of the differences in traffic loading and sealing technique. The benefits shown in Table 2, which range from 1.4 to 2.0 years, are only for the crack treatment and do not include the additional benefit provided by the chip seal.

The lack of statistical significance in sections that combined micro surfacing with crack sealing or filling was surprising. Nonetheless, these findings are tied to the way that condition categories are defined in the analysis. Particularly, for the “poor” condition category, which has a lower bound of 20%, both sections reached failure at around the same time, although the average pretreatment cracking percentage was 21.4% for the micro surfacing section and 41.9% for the micro surfacing with crack seal/fill. This suggests that there is a benefit that could not be captured statistically, but as mentioned earlier, the condition ranges were selected to be consistent with the FHWA performance criteria.

As data collection efforts continue, the accuracy of results may be improved as the amount of censored data is reduced. Also, additional test sections were constructed on U.S. Route 280 near Opelika, Alabama in 2015, as well as on U.S. Highway 169 and County State Aid Highway 8 near Pease, Minnesota in 2016. These newer sections have been in service for a shorter period but will be analyzed in the same way to determine the effects of traffic and climate on the life-extending benefit of the treatments.

For more information about this article, please contact Adriana Vargas.