- Spring 2020

Insights Gained from Balanced Mix Design Workshops

NCAT Director Randy West leads a balanced mix design workshop at the Utah Department of Transportation's central complex.

Background

Balanced mix design (BMD) is an enhanced approach to designing asphalt paving mixtures to achieve a satisfactory balance between rutting resistance and cracking resistance. Unlike the Superpave design approach, BMD focuses on optimizing mixture performance using simple mixture performance tests. BMD will provide a better way to assess mixture quality and is expected to open the door to utilizing more sustainable and innovative materials. Furthermore, implementation of simple mix performance tests as part of quality assurance will also ensure that the mixtures delivered to the project meet expected performance-related criteria.

In August 2018, NCAT completed National Cooperative Highway Research Program Project 20-07/Task 406 and developed a framework to address alternate approaches for implementation of BMD procedures that incorporate performance testing and criteria. Major outcomes of the project included survey responses from state highway agencies and asphalt contractors on their expectations for BMD, a literature review of current practices for mix design and performance testing, knowledge gaps and research problem statements, as well as a preliminary draft AASHTO standard practice and specification for BMD. The draft standards have subsequently been balloted, revised, and approved as provisional standards that will be included in the 2020 edition of the AASHTO standards for materials and tests.

Workshop Overview

To advance toward implementation, the National Asphalt Pavement Association sponsored six regional BMD workshops conducted by NCAT Director Dr. Randy West and NCAT Assistant Research Professor Dr. Fan Yin. The workshops were designed for state highway agency materials engineers who are typically decision makers on mix design and acceptance specifications, asphalt industry managers responsible for asphalt mix designs and quality control testing, and other stakeholders interested in gaining an understanding of BMD. Topics covered in the workshops included:

- - Superpave mix design limitations and refinements;

- - BMD definition and approaches;

- - Current mix design practices and modifications to improve performance;

- - Asphalt mixture performance tests;

- - Draft AASHTO standard practice and specification;

- - Knowledge gaps and research needs;

- - Implementation and partnerships between agencies and industry;

- - Case studies and ongoing research; and

- - Quality control and acceptance testing using performance tests.

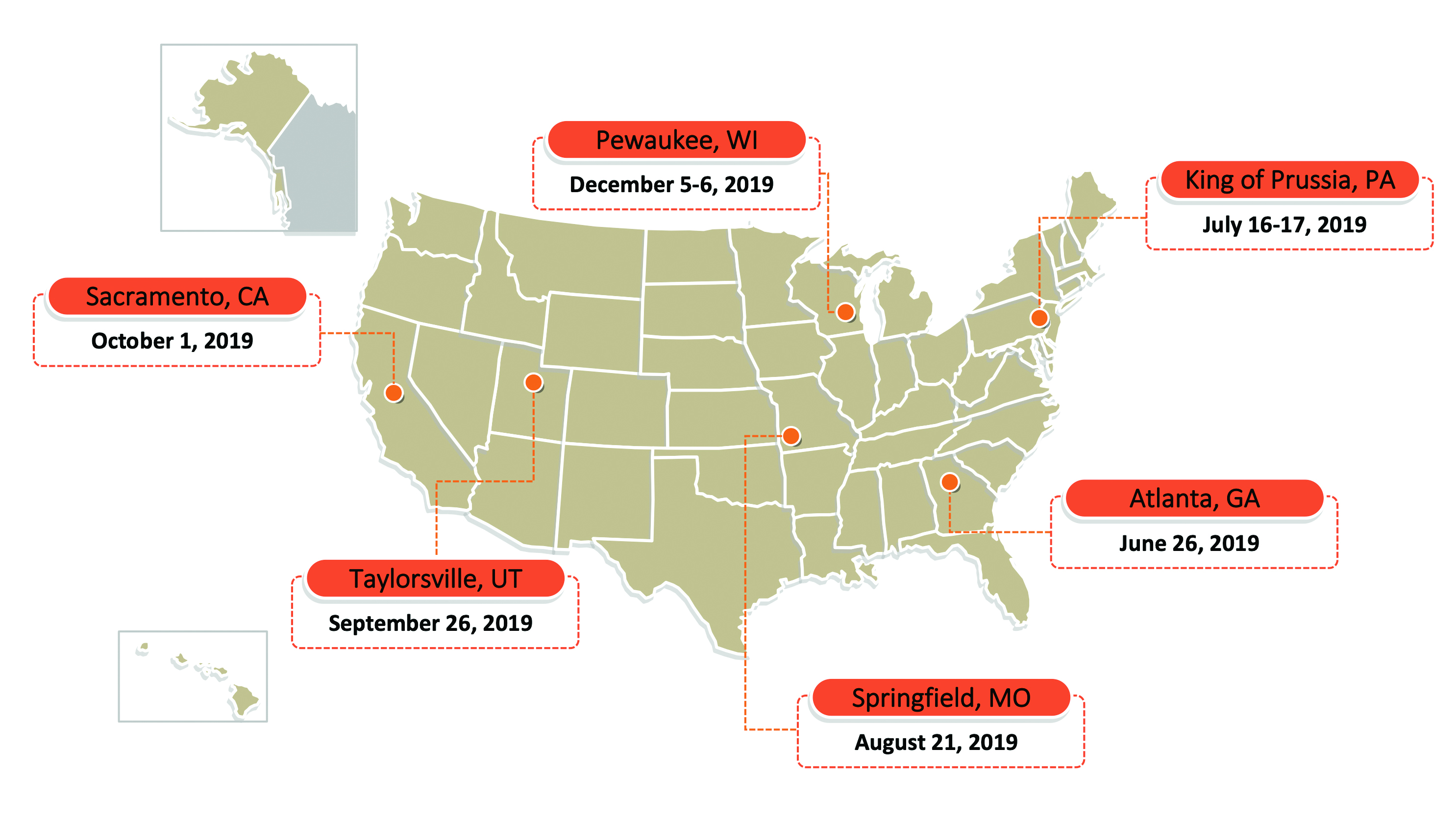

The workshops required pre-registration on a first-come, first-served basis and were free to attend with the Federal Highway Administration providing travel funding to state agency personnel. The six workshop locations were selected primarily in states highly interested in implementing BMD and those that have already engaged in efforts to evaluate mixture performance tests for asphalt mix design (Figure 1).

Figure 1. NCAT held Balanced Mix Design workshops at six locations across the country.

Overall, the workshops were a great success with a total of 261 attendees consisting of approximately 44% from asphalt contractors, 35% from federal, state, and local highway agencies, and the remainder including participants from asphalt associations, materials suppliers, testing laboratories, consultants, and academic institutions. The workshops were conducted in an interactive manner with question-and-answer sessions and open discussions throughout the schedule. Feedback from the workshop attendees was positive; the most popular topics were Asphalt Mixture Performance Tests and Mix Design Modifications to Improve Performance Results.

Workshop Highlights

Visit https://aub.ie/bmdqa for a list of questions and answers sparked by dynamic discussions during the workshops. A summary of highlights is provided below.

Many state DOTs expressed interest in implementing BMD because they have not seen much improvement in mix performance after implementing Superpave, with some poor mixes being designed and produced that still met all volumetric requirements. BMD was also seen as a better approach to evaluating and approving innovative products such as rejuvenators, special additives, and polymer modifications.

Contractors generally expressed a belief that performance test results would provide a better indication of mix quality than volumetric properties. Contractors also noted that BMD should provide more flexibility during mix design and allow more opportunities to use innovative mix components to stay competitive in the low-bid environment.

Some of the biggest hurdles to BMD implementation are the selection of performance tests and criteria, performance testing during production (need test methods with quick turnaround on results to limit risks), and improvements in binder specification.

For state highway agencies interested in benchmarking current mix designs to establish performance criteria, NCAT recommends that priority should be given to mixes with known histories of field performance. The criteria should be set in a way to eliminate mixes that failed prematurely in the field. Meanwhile, contractors should conduct performance tests on their most common mixes to have an idea of how their mixes compare to others in the state.

A few state highway agencies have established requirements on the minimum asphalt binder content to mitigate “dry” mix issues. However, NCAT feels that this may not be a good practice because different aggregates will have different Gsb values and asphalt absorption values so the appropriate minimum asphalt content can be very different for different aggregates used within a state.

There are many different types of asphalt rejuvenators (including both bio-based and petroleum-based products) available on the market, but their ability to effectively improve cracking test results, especially after mix aging, varies significantly from product to product. Although numerous rejuvenators have shown promising laboratory results with mixtures containing high RAP contents and/or RAS, there have also been a few unsuccessful cases where the rejuvenated RAP/RAS mixtures failed prematurely in the field. Currently, there is no established laboratory procedure for the evaluation and approval of rejuvenators. NCAT is working on a research project for South Dakota DOT on this topic. Texas A&M University recently completed NCHRP Project 09-58, which provided guidelines on the use of recycling agents for asphalt mixtures with high RAP and RAS binder ratios. The project final report will be published online soon as NCHRP Report 927. One factor that will impact the success or failure of a particular rejuvenator is its dosage rate. In theory, the dosage of rejuvenator should be determined based on the amount and properties of RAP and/or RAS binders. Blending charts (based on extracted binder blends) and mixture performance testing appear to be the two most promising approaches for determining the optimum dosage of rejuvenator.

Caution should be exercised when adding chemical additives (including rejuvenators, warm mix asphalt, and liquid anti-strip agents) into asphalt mixes containing polymer modified binders, as some of the additives may be not chemically compatible with the specific polymer used for asphalt modification. In such a case, the resultant mix will not perform as well as expected. This is another argument for the use of mixture performance tests in mix design and QA to assure that all of the individual components are compatible and can contribute to the performance of the mixture as expected.

It is NCAT’s opinion that the HWTT test temperature should be selected based on the climate of a project rather than the PG of the virgin binder used in the mix because the virgin binder grade would not account for the effects of recycled binders and other additives on the composite binder stiffness.

NCAT is working on a schedule for five additional one-day BMD workshops in 2020. Dates and locations are still to be determined. A national BMD conference is also being planned for March 31-April 1, 2021 in Nashville, TN. The 2020 workshops and conference are funded through NCHRP 20-44(19), Facilitating BMD Implementation. The project final report was recently published online as NCHRP Report 927.

For more information about this article, please contact Fan Yin.