- Spring 2019

Crack Sealing: A Cost-Effective Option for Extending Pavement Life

Cracking is a primary mode of distress in flexible pavements, and if left untreated, it may lead to accelerated deterioration and potholing, further reducing pavement serviceability. Cracks can be sealed as part of a pavement preservation program to prevent water infiltration and loss of load-carrying capacity, either as a stand-alone treatment or in combination with other preservation activities.

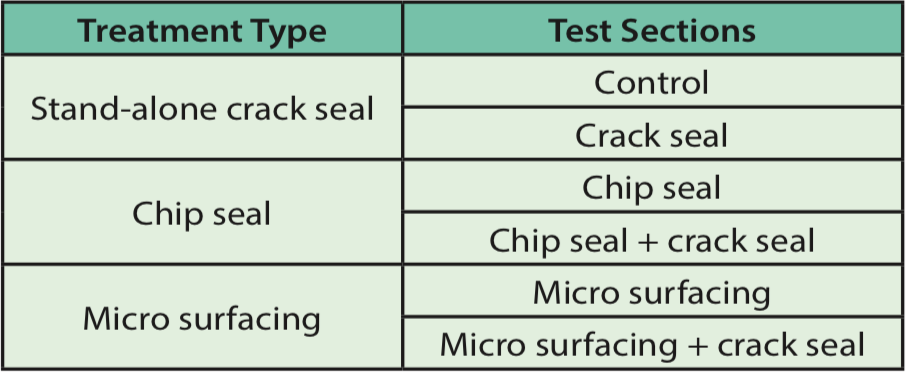

NCAT’s Pavement Preservation Group study has been evaluating the performance of crack sealing treatments since 2012. There are three pairs of test sections on Lee Road 159 (NCAT’s low-volume test site) that can be directly compared to assess the effect of crack sealing, as shown in Table 1.

Table 1. Pavement Preservation Group test sections on Lee Road 159.

Crack sealing was performed in three of the test sections, one as a stand-alone and two in combination with other surface seals. In all cases, the material used was an asphalt-based product applied hot as specified in ASTM D6690. In the inbound lane, cracks were routed and cleaned by compressed air and heat lanced prior to sealing with a reservoir configuration. In the outbound lane, cracks were only cleaned by compressed air and heat lanced before being filled using an overband configuration.

Prior to treatment application, existing cracking was mapped and quantified for all test sections. In general, crack sealing was applied to sections with a higher amount of cracking compared to their counterparts, which only received a surface treatment. Since then, cracking performance has been monitored periodically among other indicators. The results show that reappearance of cracking has been significantly delayed in sections that were treated with crack sealing.

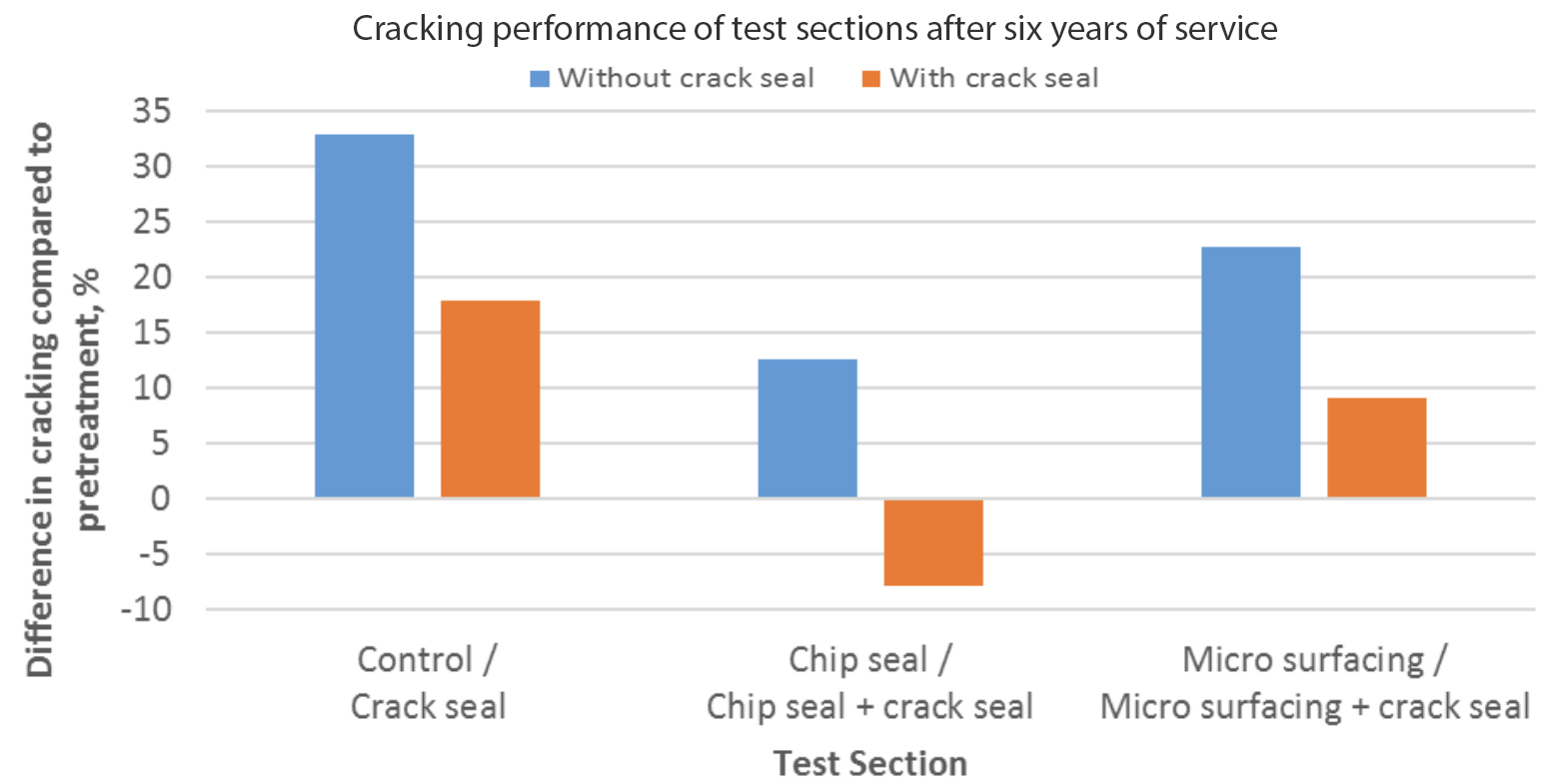

Figure 1 shows the amount of cracking in each section after more than six years of service compared to the pretreatment condition (difference = current – pretreatment). While non-sealed sections have developed 12 to 33% of additional cracking compared to their initial condition, crack sealed sections developed less than half of that amount. Furthermore, in the case of the chip seal with crack sealing, the section has not yet returned to its pretreatment cracking level.

Figure 1. Cracking performance of test sections.

As expected, crack sealing has not affected pavement rutting and has not had an effect on IRI during the first six and a half years since treatment.

The benefits of crack sealing can easily be identified from a visual assessment (Figure 2). Testing with a falling weight deflectometer has also been performed periodically to monitor the integrity of the pavement structure, which uses deflection basin parameters to characterize the structural condition of pavement layers. In general, treated sections remain structurally sound with some exceptions in the stand-alone crack sealed section. Better results have been obtained when combining crack sealing with other surface treatments.

Figure 2. Micro surfacing sections: stand-alone (left) and with crack sealing (right).

From the results obtained to date, it can be concluded that the use of crack sealing as part of a preservation treatment can successfully extend pavement life. The benefits ultimately depend on the initial condition of the pavement and are evident in the amount of cracking developed over the study period and the overall structural condition. To date, the overall pavement condition of the test sections can be classified as “good” to “fair”. Data collection and analysis efforts will continue in the ongoing Pavement Preservation Group study with the objective of determining the life-extending and condition-improving benefit of all treatments based on initial condition, traffic level, and climate.

For more information about this article, please contact Adriana Vargas.