- Spring 2019

Micro Surfacing Improves Pavement Performance on Lee Road 159

Overall condition of scrub cape seal on Lee Road 159

As agencies face the challenge of maintaining their existing infrastructure with limited resources, pavement preservation treatments have gained popularity as a cost-effective alternative for extending pavement life. Micro surfacing is a pavement preservation treatment that can be used to protect the pavement structure from moisture and correct minor surface defects. As with other preservation treatments, performance of treated sections depends in great part on proper candidate selection and timely intervention. Estimates for pavement life extension typically range from four to seven years; however, the criteria for defining performance varies among sources.

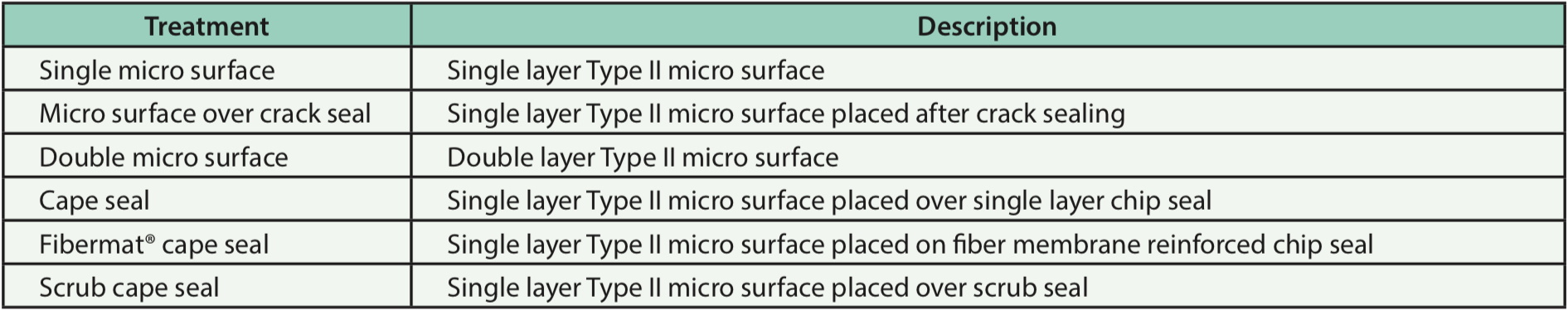

As part of the NCAT-MnROAD Pavement Preservation Group (PG) Study, six micro surfacing test sections were placed on Lee County Road 159, a low traffic volume road located in Auburn, Alabama. Treatments included single, double and cape seal applications and have been monitored periodically since 2012 to assess structural condition, surface distress, and ride quality. In addition, two sections were left untreated to serve as control. Table 1 provides a description of the test sections.

Table 1. Cold recycling mixture strength requirements.

A Type II micro surfacing treatment was designed for all applications on Lee County Road 159 following the guidelines from the International Slurry Surfacing Association (ISSA). The mix included limestone aggregate, portland cement as the mineral filler, and a CSS-1HP asphalt emulsion, and was placed at a target application rate of 18 to 20 lb/yd 2.

Surface Distress

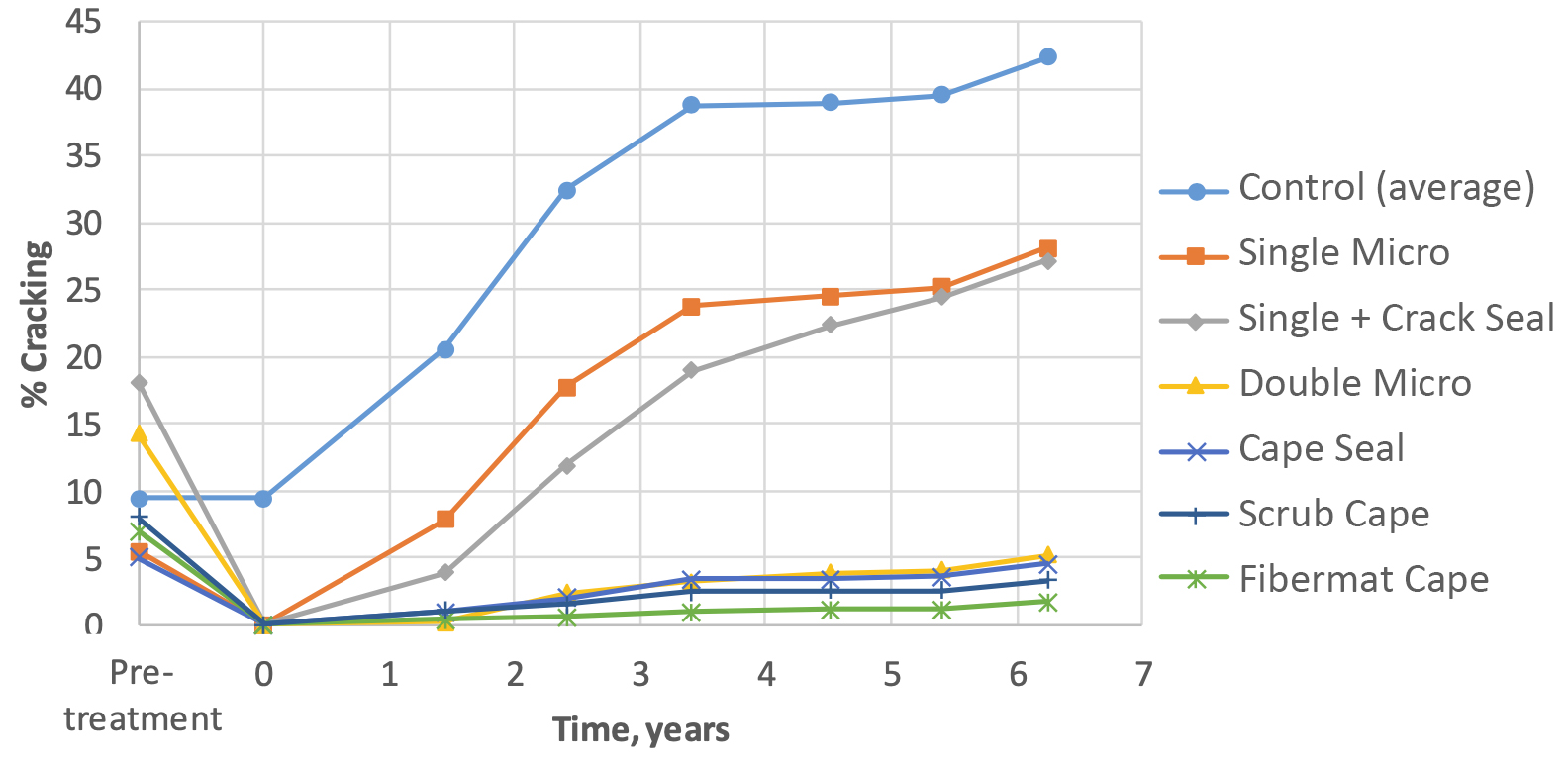

As sections approach their seventh year in service, the main type of distress observed has been cracking. Even though micro surfacing is not considered a crack mitigation treatment, its application has improved cracking performance compared to the control sections, as shown in Figure 1. While the control sections have deteriorated rapidly, treated sections have developed far less cracking since the treatments were constructed. Furthermore, the sections can be separated into three groups based on performance: untreated, single layer applications, and multi-layer or cape seal applications. As expected, more robust treatments have resulted in improved cracking resistance.

Figure 1. Cracking progression over time.

To provide a fair assessment of treatment performance, it is important to take into account the condition of the pavement at the time of application. Multi-layer and cape seal applications have not yet returned to their pretreatment level of cracking and remain in good condition, with less than 5% cracking by area. Single-layer applications have over 20% cracking. However, the section that included crack sealing exhibited a significantly higher amount of pretreatment cracking. When crack sealing was used in combination with micro surfacing, the test section that started with 18% cracking (pretreatment) increased to 27% after more than six years of service, for a change of only 9%. On the other hand, the stand-alone single layer micro surface increased from 5% pretreatment cracking to 28% currently, for an increase of 23% cracking over the study period.

Rutting has not been an issue for the sections on Lee Road 159. Pretreatment levels ranged between 4 and 7 mm, which is considered good to fair condition. On average, treatments were effective in correcting these minor levels of permanent deformation, and rut depths are under 5.5 mm after over six years of service.

Ride Quality

Prior to treatment application, most test sections had a good ride quality, with IRI values under 95 in/mi. Little variation has been observed in roughness over the course of more than six years, with sections maintaining a relatively constant IRI.

Structural Condition

Periodic falling weight deflectometer (FWD) testing is performed in the test sections to assess the structural health of the pavement. Although preservation treatments are not generally used to improve structural capacity, structural condition is monitored over time to determine if the treatments affect the structural condition. The micro surfacing sections on Lee Road 159 have been successful in protecting the structural integrity of the pavement without significant variations in pavement deflections over time.

As the PG study begins another cycle of data collection, the results observed over the first six years are promising. Sections treated with micro surfacing show improved performance compared to the control sections and have been effective in extending pavement life.

While Lee County Road 159 has the oldest test sections of the PG Study, additional treatments were applied on US 280 in Alabama in 2015, as well as on CSAH-8 and US 169, near Pease, Minnesota in 2016, providing a range of conditions that cover low and high traffic volumes in both southern and northern climates. Results in the upcoming years will provide valuable information that will help agencies estimate the performance of their treated pavement more accurately according to their local conditions.

For more information about this article, please contact Adriana Vargas.