- Spring 2024

FDOT Sponsored Research to Advance RAP Asphalt Mixtures

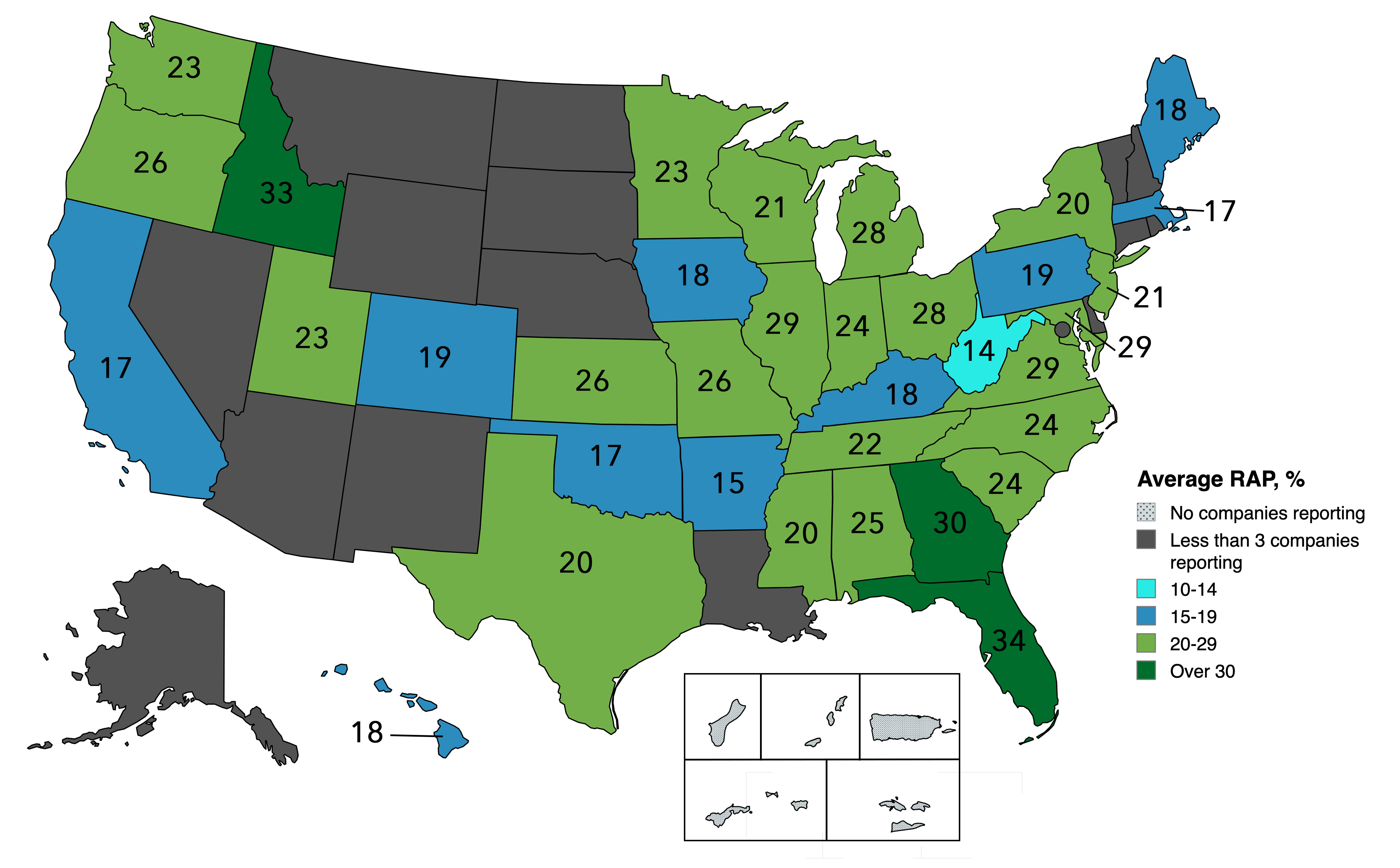

The Florida Department of Transportation (FDOT) is one of the nation’s leading highway agencies using reclaimed asphalt pavement (RAP) in asphalt mixtures. According to the 2022 asphalt pavement industry survey, the estimated average RAP content of asphalt mixtures in Florida is 34%, surpassing the national average by 11.8%1. The successful use of RAP not only allows FDOT to stretch its resurfacing funds but also significantly conserves natural resources.

Figure 1. Estimated Average Percentage of RAP Used in Each State, 2017-20211.

FDOT has adopted two key initiatives to ensure the satisfactory performance of RAP asphalt mixtures: establishing a statewide RAP stockpile database and requiring a softer asphalt binder for mixtures containing over 15% RAP. Recently, FDOT has been interested in further improving the cracking performance of RAP asphalt mixtures through the Corrected Optimum Asphalt Content (COAC) approach– an approach successfully employed in neighboring states Georgia and South Carolina.

The COAC approach recognizes the challenge posed by the high viscosity and stiffness of RAP binder, acknowledging that not all of it may be activated during mixing to coat and bind aggregates like virgin binder. The percentage of the activated RAP binder is defined as recycled binder availability (RBA), which varies from 0% to 100%, representing the most conservative and optimistic conditions, respectively. By compensating for inactive RAP binder with additional virgin binder, the COAC approach improves mixture durability and cracking resistance.

In December 2021, FDOT sponsored a pivotal research study at NCAT to evaluate the suitability of the COAC approach in Florida conditions2. The study recommended an 80% RBA limit based on an extensive literature review, considering the performance grade (PG) of RAP binders and mixing temperatures of RAP mixtures prevalent in Florida. With 80% RBA, it is assumed that 80% of the RAP binder can be activated while the other 20% cannot.

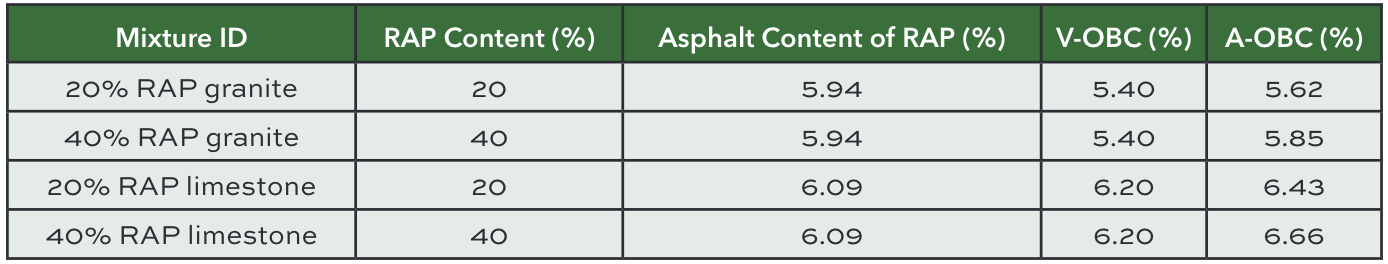

Laboratory experiments were conducted to assess the impact of 80% RBA on the performance properties of existing RAP mixtures. Four Superpave SP-12.5 mixtures were tested, including two low-absorption granite (GRN) mixtures and two high-absorption limestone (LMS) mixtures at 20% and 40% RAP contents. The 20% RAP mixtures used a PG 76-22 polymer-modified asphalt (PMA) binder, while the 40% RAP mixtures used a PG 52-28 binder per FDOT specifications. Each mixture was tested at two asphalt binder contents: the volumetric optimum (V-OBC), and the RBA-adjusted optimum (A-OBC). A-OBC was calculated based on V-OBC, the RAP content of the mixture, the asphalt content of the RAP, and the recommended RBA limit (i.e., 80%). As shown in Table 1, A-OBC was approximately 0.2% higher than V-OBC for the 20% RAP mixtures, and about 0.45% higher for the 40% RAP mixtures.

Table 1. Comparison of V-OBC versus A-OBC

The laboratory testing plan evaluated the rutting and cracking resistance of each RAP mixture at V-OBC vs. A-OBC using various balanced mix design (BMD) performance tests. Adding more virgin binders in consideration of 80% RBA significantly improved the cracking resistance of the RAP mixtures, especially for 40% RAP. The 40% RAP mixtures with PG 52-28 binder showed similar cracking resistance as the 20% RAP mixtures with PG 76-22 PMA binder after RBA adjustments for both mixtures. Adding more virgin binders was detrimental to the rutting resistance of the 40% RAP mixtures, but did not affect the 20% RAP mixtures with PG 76-22 PMA binder. This highlights the benefit of polymer modification, enabling the use of more asphalt binder while avoiding rutting issues in mixtures. Although the 40% RAP mixtures at A-OBC showed increased rutting potential based on laboratory testing, they are not expected to experience rutting in the field, given their use as non-surface layers in Florida. Overall, the test results showed that using the COAC approach with 80% RBA could improve the overall performance of RAP mixtures in Florida.

A comparative cost-benefit analysis concluded that a modest two-month extension in pavement service life (from 15 years) would suffice to justify the cost of the additional virgin binders in a 3-inch mill-and-resurface project utilizing RAP mixtures with 80% RBA.

The promising results obtained in the study position FDOT to potentially implement the COAC approach with 80% RBA, furthering the economic, environmental, and performance benefits of RAP asphalt mixtures in Florida.

Contact Fan Yin for more information about this research.

- National Asphalt Pavement Association (NAPA). 2022. Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage. NAPA Information Series 138.

- Yin, F., Taylor, A., Chen, C., Moraes, R., Musselman, J., and Tran, N. 2023. Determining the Effect on Asphalt Mixture Performance by Increasing New Asphalt Binder Content Due to Inactive RAP Binder in the Mixture. Florida Department of Transportation BEC 79 Final Report.