- Fall 2022

Investigating Night Paving with Cold In-Place Recycling Mixtures using Engineered Emulsions

When specifying night paving, some state agencies only allow foamed cold in-place recycling (CIR) mixes instead of emulsion CIR mixes. Emulsion CIR mixes of the 1980s and 1990s did not gain strength as quickly as foamed mixes and were stickier, increasing the risk of material pickup. This issue could be mitigated during daytime paving with sunlight and warmer temperatures expediting the emulsion break time. However, with cooler temperatures during night paving, foamed mixes are assumed to build strength faster and be less prone to raveling than emulsion CIR mixes.

New engineered emulsions are cationic systems designed to break quicker and build cohesion in the mixture. This new generation of emulsions offers appropriate mixing time, workability, moisture resistance, and superior strength compared to older CIR methods.

NCAT worked with Ingevity in January 2022 to investigate using engineered emulsions in night paving applications. The objective was to determine if engineered emulsion mixtures could demonstrate strength gain and raveling resistance at a similar rate as foamed mixtures in laboratory testing using short-term lab curing. Two engineered emulsions, including one containing a small amount of rejuvenator (engineered emulsion #1), were tested alongside a foamed CIR mix. All three mixtures used the same RAP source with 1% cement and had the same moisture and residual binder contents.

Despite having the same intended applications, the two methods (foamed and emulsion CIR) have different specifications. For example, foamed CIR mixes are typically required to pass a minimum indirect tensile strength (ITS) and tensile strength ratio (TSR) from indirect tension testing, while emulsion CIR mixes are tested for Marshall stability and retained strength from Marshall testing. The two tests are also performed at different temperatures. The difference in test methods makes head-to-head comparisons of the two CIR techniques challenging.

The two CIR methods were assessed head-to-head by comparing the engineered emulsions and the foamed mix using current industry-accepted tests, identical testing conditions, and, when applicable, acceptable specification criteria. A lower curing temperature of 10°C (50°F) was used to simulate the colder environment of night paving. Specimens were tested after four hours of curing to simulate strength gain a short time after construction as well as after the standard 72 hour cure for emulsion CIR mixtures.

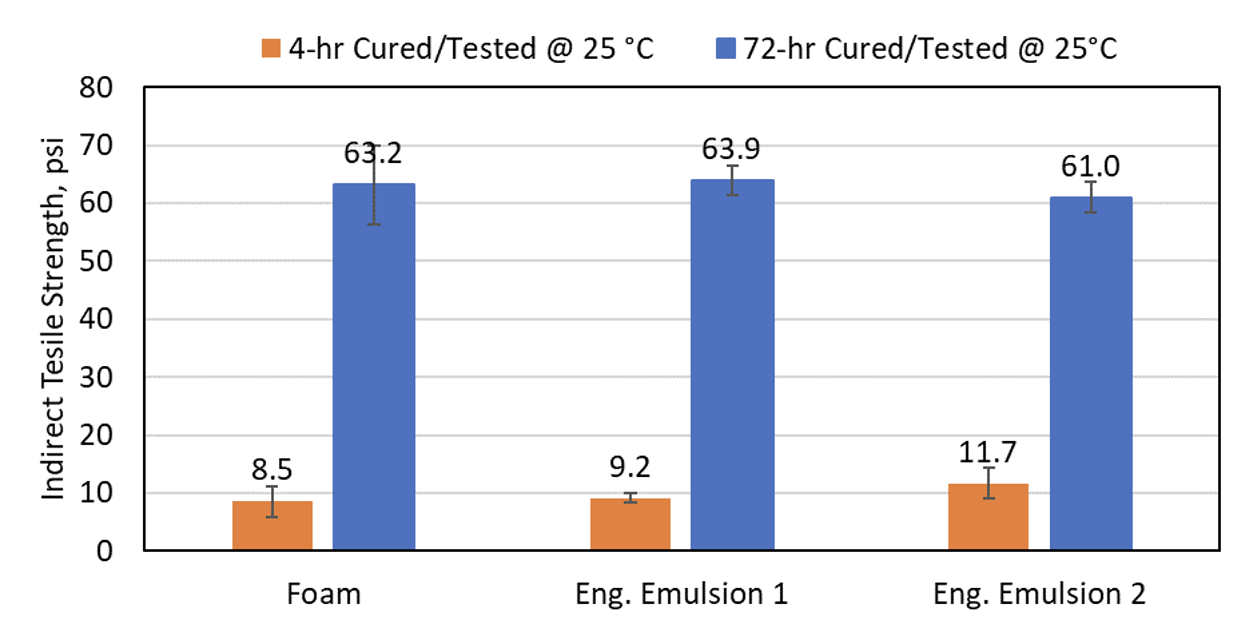

Figure 1 shows the dry ITS strengths at the two different conditioning times. All three designs had comparable strengths after being fully cured at 40°C for 72 hours and tested at 25°C. More importantly, the early strengths of the two engineered emulsions were slightly higher, but statistically equivalent to the foamed mixture after four hours of conditioning at 25°C.

The engineered emulsion designs demonstrated equal or better strengths in the fully cured and short-term cured conditions. Raveling potential of the three mixtures was determined using the rubber hose abrasion test following ASTM D7196-18. The engineered emulsions yielded lower mass loss (i.e., better raveling resistance) than the foamed CIR mix.

Figure 1. Comparison of Foam vs. Engineered Emulsion CIR Mixtures at 25°C

This study demonstrated the potential for using engineered emulsions in night paving applications, and the findings from this study warrant further exploration with a field trial. Finally, additional laboratory testing with other engineered and non-engineered emulsions should be conducted to better classify emulsions that could be suitable for night paving.

For more information about this article, please contact Nathan Moore.