- Fall 2020

Rehabilitating Concrete Pavements with Slab Fracturing

The benefits of using asphalt overlays for rehabilitation of Portland cement concrete (PCC) pavements are grounded in economics and long-term performance. The Federal Highway Administration reports that the U.S. has 108,603 lane miles of composite pavements (PCC overlaid with asphalt), which is nearly double the lane miles of PCC-surfaced pavements. This means that nearly two-thirds of the concrete pavements in the U.S. have been overlaid with asphalt. However, a persistent problem with asphalt overlays on PCC pavements is reflective cracking of joints and cracks through the asphalt overlays over time. Ultimately, reflective cracking leads to a shortened performance life of the overlay. Rather than removing the concrete, which can be costly to the owner agency and increase delay time for the traveling public, slab-fracturing techniques can be used prior to placement of an asphalt overlay to significantly reduce stress concentrations at concrete joints and cracks.

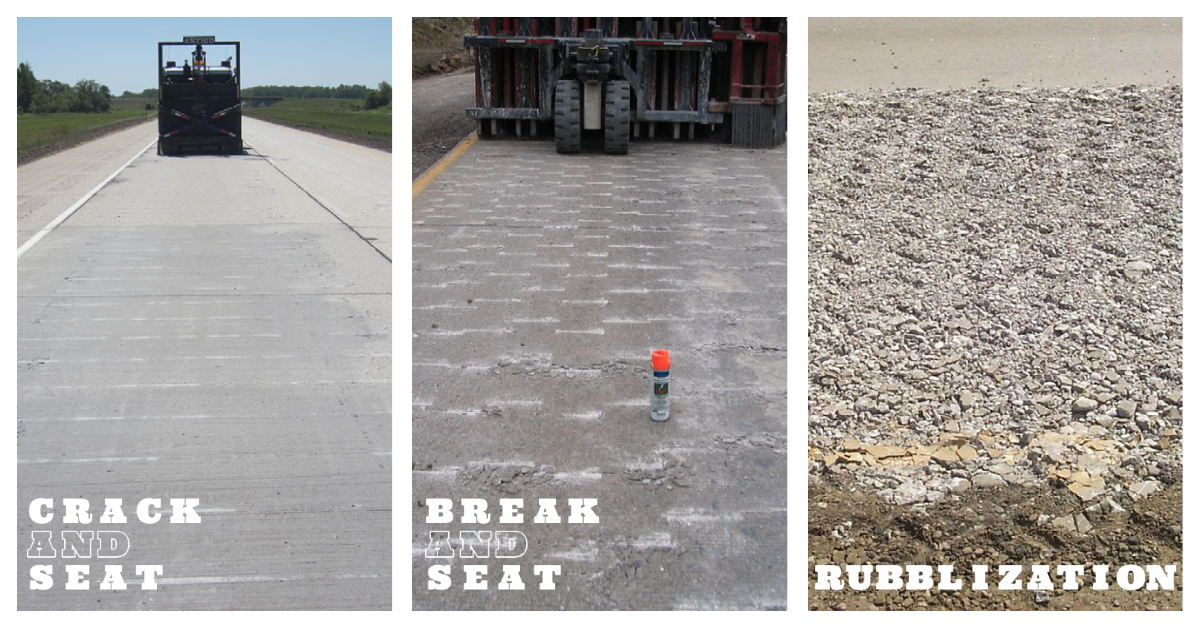

Slab-fracturing techniques include three methods: crack and seat for PCC without steel reinforcement, break and seat for PCC with steel reinforcement, and rubblization for any type of concrete pavement. Crack and seat is intended to reduce the effective slab length of PCC pavements by producing tight surface cracks. Break and seat is similar but typically requires greater fracturing effort. The rubblization process typically fractures slabs into fragments with a nominal size of 4 to 8 inches. Since the existing pavement remains in-place, there are no hauling or disposal costs, resulting in substantial cost savings for state agencies.

Slab Fracturing Techniques for PCC Rehabilitation

Researchers at NCAT recently completed a project sponsored by the National Asphalt Pavement Association (NAPA) to synthesize historical and recent experiences with rehabilitation methods of PCC pavements with asphalt overlays. A survey of stakeholders indicated that crack and seat and rubblization are more popular than break and seat for PCC rehabilitation. Most PCC rehabilitation projects have more than 4 inches of asphalt overlay placed on fractured slabs. Although a majority of state agencies still use the AASHTO 1993 design method, Wisconsin uses the AASHTO 1972 design method; Indiana, Missouri, and Wyoming use Pavement ME Design; and California, New York, and Illinois use their own mechanistic-empirical design methods.

NCAT researchers also analyzed Long-Term Pavement Performance SPS-6 experiment data to compare slab fracturing methods to alternative concrete rehabilitation treatments such as minimum and maximum restoration of PCC and overlays with sawed and sealed joints. They found that rubblized PCC with more than 5 inches of asphalt overlay practically inhibits reflective cracking. According to the statistical analysis, there are no significant differences in performance measures of smoothness, rut depth, and longitudinal cracking for the different treatments involving asphalt overlays on PCC.

NAPA IS-117 recommends that in order to eliminate reflective cracking, crack and seat and break and seat projects should have less than 5 percent exceeding Epcc = 1000 ksi. However, as shown in Figure 2, NCAT researchers found that most of the SPS-6 projects had slab moduli above the 1000 psi threshold but still had good reflective cracking performance. Thus, the IS-117 recommended threshold for Epcc is not suitable for recent slab fracturing projects. The researchers used a finite element analysis to determine that rubblized PCC with more than 8 inches of asphalt overlay could be a perpetual structure if the foundation is strong enough.

Figure 1. Distribution of Back-Calculated Moduli of Fractured Slabs

In addition, two case studies were documented: one crack and seat project in Wyoming and one rubblization project in Colorado. These projects used different design methods. Wyoming used the mechanistic-empirical methodology to determine the asphalt overlay thickness, while Colorado used the AASHTO 1993 design method. The details are covered in NCAT Report 20-03, Benefits of Rehabilitating Concrete Pavements with Slab Fracturing and Asphalt Overlays.

The key findings of this project are also recorded in a NAPA webinar with the same title. The project outcome informs owner agencies and the industry that slab fracturing techniques are the most effective PCC rehabilitation methods.

For more information about this article, please contact Fan Gu (left) or Benjamin Bowers (right).