- Fall 2020

Compounding Mixture Durability by Making Incremental Specification Improvements

When Dave Brailsford became the performance director of the British Olympic cycling team in 2003, it had been almost a century since the team had won its only Olympic gold medal. The team’s performance was so underwhelming that one manufacturer was reluctant to sell them bikes due to their negative impression. Instead of making a major disruptive change, Brailsford and his coaches committed to a strategy that he referred to as “the aggregation of marginal gains” to compound incremental improvements in every aspect of cycling. In just five years, the British cycling team dominated their events at the 2008 Olympic Games, winning eight gold medals while the second-place French team won only two. The British team continued to outperform other Olympic teams, winning eight gold medals in 2012 and six in 2016.

Following a similar approach, the Georgia Department of Transportation (GDOT) has made incremental changes to their standard construction specifications over the years to improve the durability of asphalt mixtures containing RAP. Based on an in-house study, GDOT developed the corrected optimum asphalt content (COAC) approach for asphalt mix designs incorporating recycled materials with implementation of the 75:25 COAC in 2012. With this approach, 75% of the RAP binder was credited to the total asphalt binder in the mix, so additional virgin asphalt binder in the amount of 25% of the RAP binder was added to the volumetric optimum binder content determined at 4.0% design air voids per AASHTO R 35-09 Section 10.5. Based on the positive effect of this change, GDOT further enhanced the durability of asphalt mixtures in the state by implementing the 60:40 COAC in 2019, thus increasing the amount of virgin asphalt binder added to the optimum binder content from 25% to 40% of the RAP binder.

Like several other states, GDOT has been waiting for recommendations drawn from the Cracking Group experiment at the NCAT Test Track to select a cracking test for implementation. As the indirect tension asphalt cracking test (IDEAL-CT, ASTM D8225-19) shows positive correlations with the cracking performance of the surface mixtures after five years of heavy truck traffic, GDOT sponsored a study at NCAT with the goal of implementing this test for a balanced mix design approach to further improve the durability and cracking performance of asphalt mixtures in Georgia. The study includes three main tasks: (1) determine the effect of COAC ratios on the cracking and rutting performance of asphalt mixtures; (2) benchmark the cracking tolerance index (CTindex) of plant mixes being produced in Georgia; and (3) compare the CTindex between laboratory-produced and plant-produced 60:40 COAC mixtures. Results will help determine preliminary CTindex thresholds for future implementation in GDOT specifications for asphalt mix design approval and acceptance testing. Laboratory testing for the first two tasks has been completed, with preliminary results as follows.

Effect of COAC Ratios on Cracking and Rutting Resistance of Asphalt Mixtures

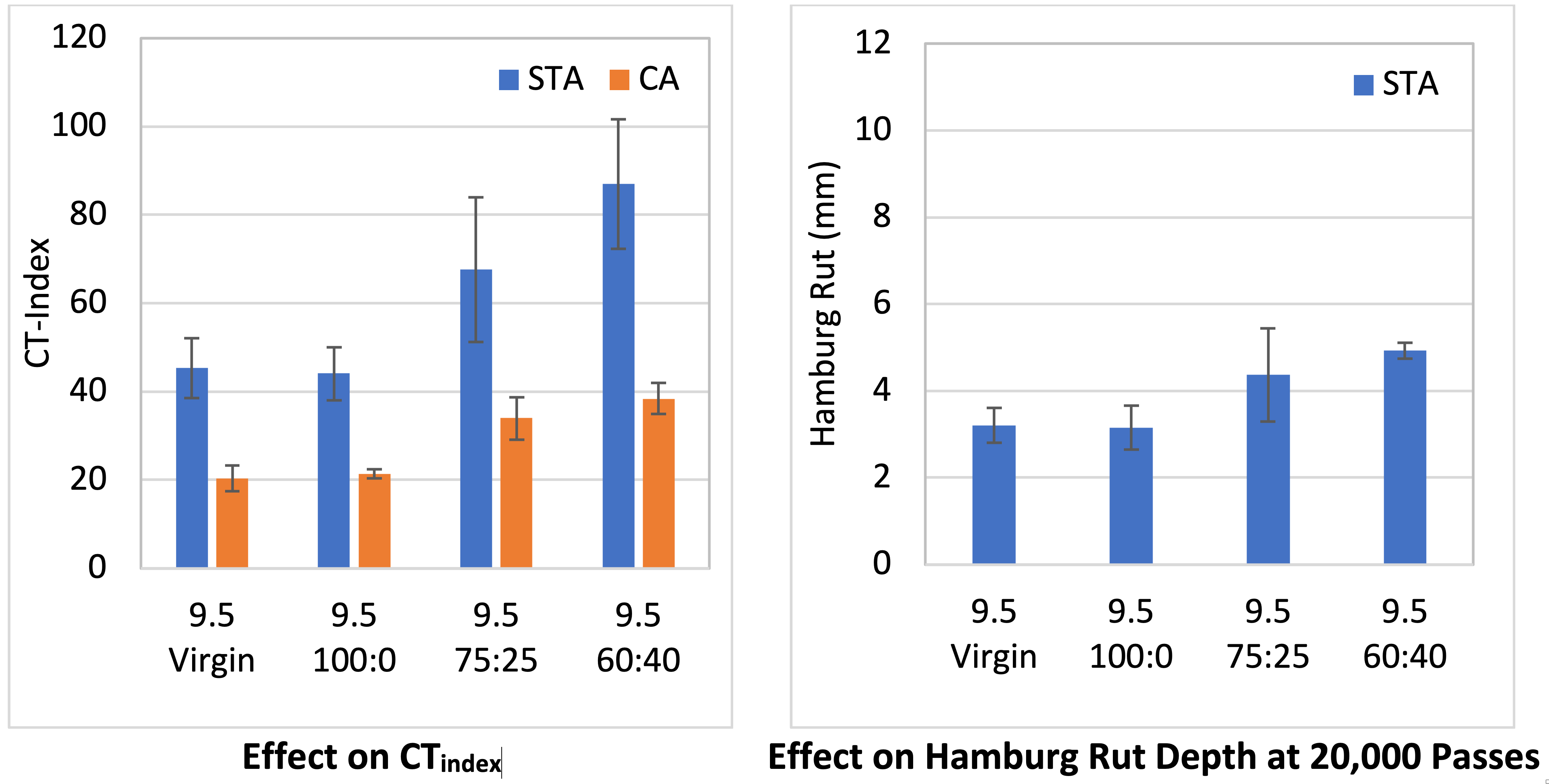

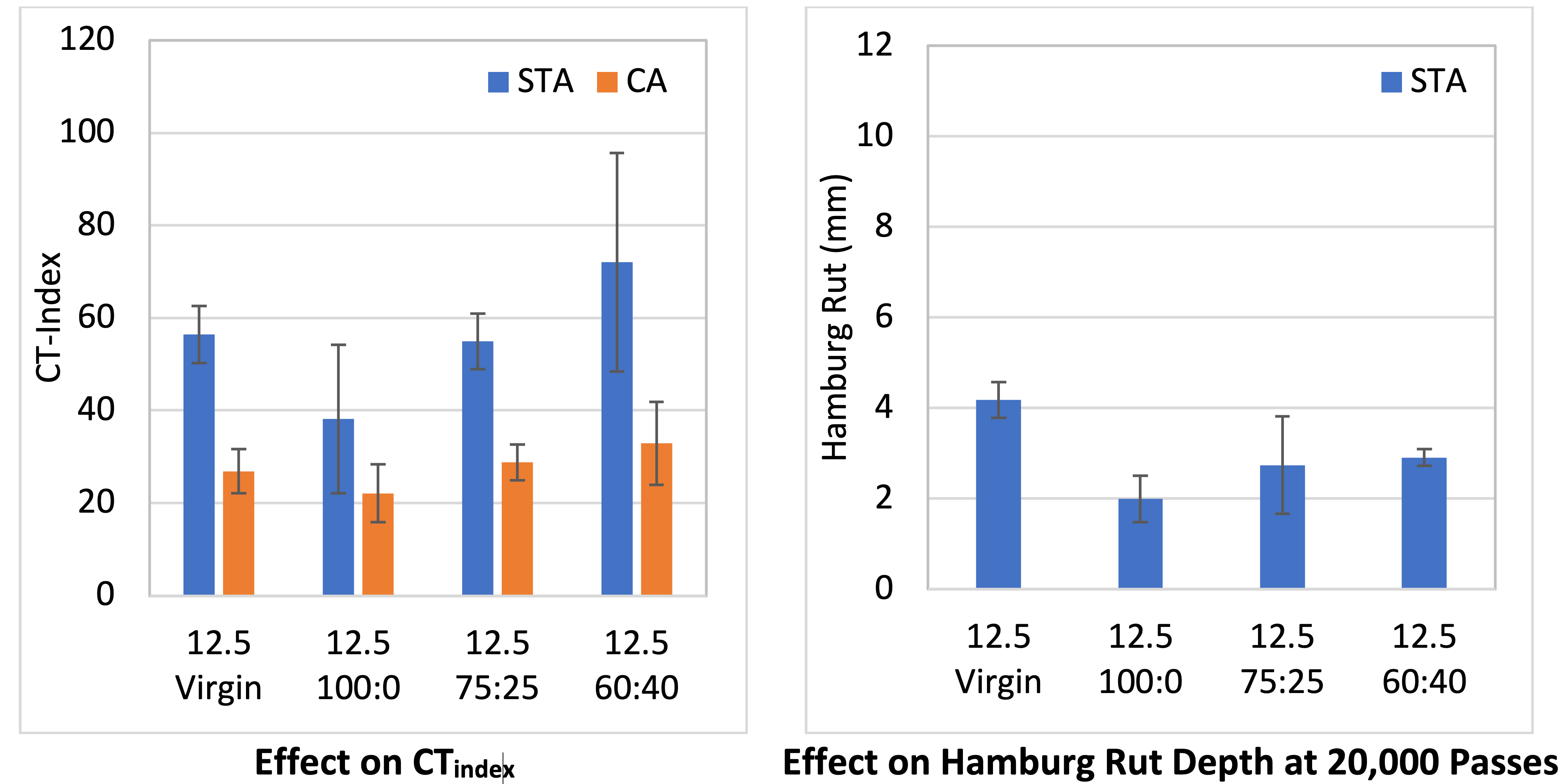

Figures 1 and 2 show the effect of COAC ratios on the cracking and rutting resistance of a 9.5 mm and a 12.5 mm NMAS Superpave mixture, respectively, using the IDEAL-CT and Hamburg wheel tracking test. For each NMAS, a virgin mix and a 30% RAP mix, both designed with a PG 64-22 binder and approved by GDOT, were selected for this evaluation. The 30% RAP mix design was tested at three COAC ratios: 100:0, 75:25 and 60:40. The IDEAL-CT was conducted in accordance with ASTM D8225-19 on lab-mixed, lab-compacted (LMLC) specimens that had been short-term oven aged (STA) for four hours at 135oC and then critically aged for an additional eight hours at 135oC prior to being compacted to the target 70.5% air voids. Hamburg testing was conducted at 50oC in compliance with AASHTO T 324-19 on LMLC specimens short-term oven aged and compacted to the target 70.5% air voids.

The changes to COAC that GDOT made to their standard construction specifications over the years have made a positive impact on CTindex and cracking resistance, while having a minor impact on the rutting resistance for both 9.5 mm and 12.5 mm Superpave mixtures. In fact, the CTindex values for the 9.5 mm mixtures with 75:25 and 60:40 COAC ratios are much higher than that of the 9.5 mm virgin mixture. The CTindex values for the 12.5 mm mixtures with 75:25 and 60:40 COAC ratios are also similar and slightly higher than that of the 12.5 mm virgin mixture.

Figure 1 Effect of COAC Ratios on Cracking and Rutting Resistance of a 9.5 mm Superpave Mix

Figure 2 Effect of COAC Ratios on Cracking and Rutting Resistance of a 12.5 mm Superpave Mix

CTindex of Plant Mixes Being Produced in Georgia

The IDEAL-CT was also conducted on plant-produced asphalt mixtures sampled by GDOT for all mix types across the state during the 2019 and 2020 construction seasons. These mixtures were brought to the NCAT laboratory where they were reheated and reduced to the sample size for preparing test specimens. Two types of plant-mixed, lab-compacted (PMLC) specimens were prepared at the target 7+-0.5% air voids: one using reheated plant mix and the other using reheated plant mix plus an additional eight hours of critical oven aging at 135oC.

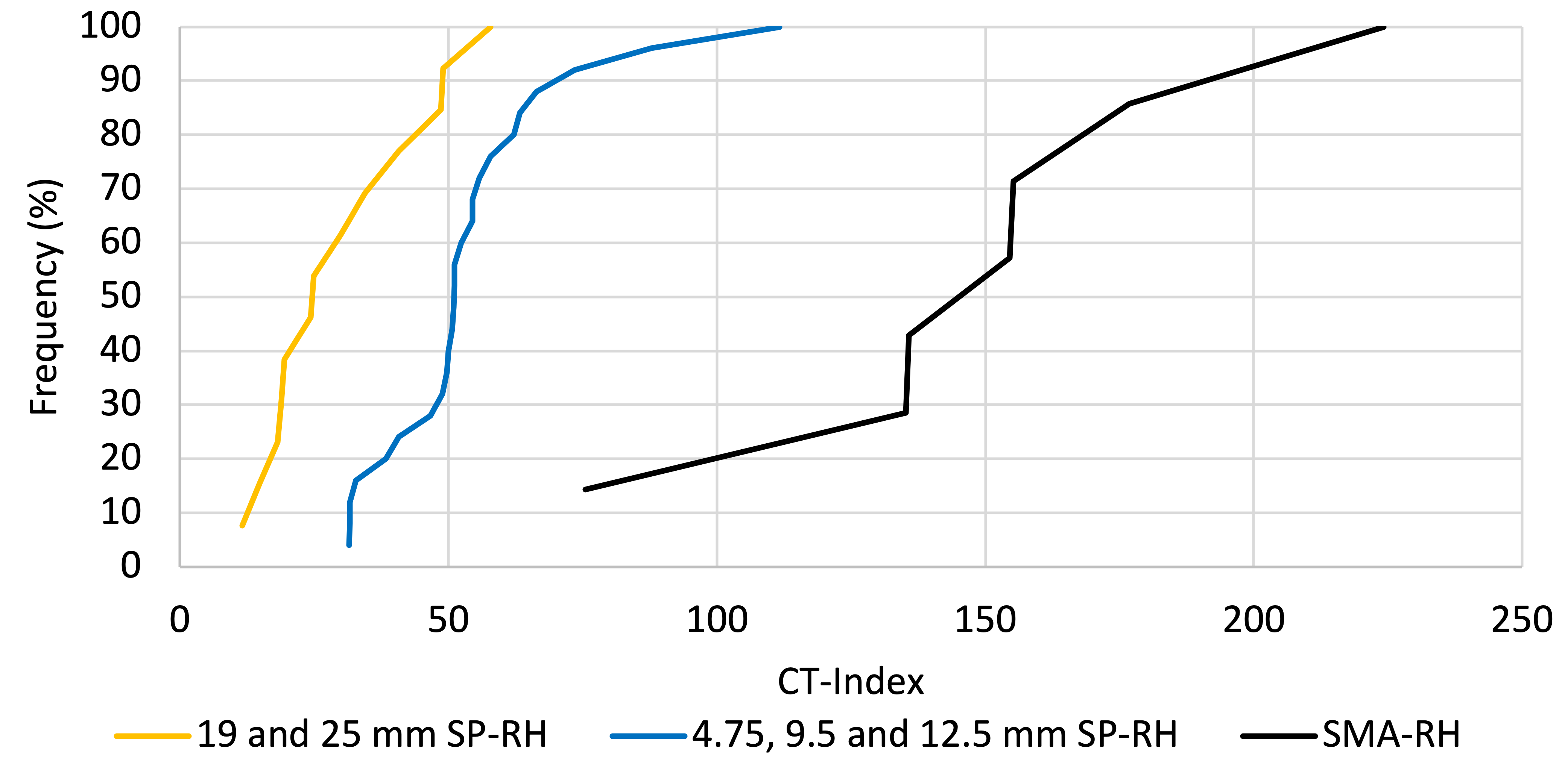

Figure 3 shows cumulative distributions of CTindex results for the reheated plant mix specimens. There are significant differences in CTindex results between SMA, surface mixes (i.e., 4.75, 9.5 and 12.5 mm NMAS) and intermediate/base layer mixes (i.e., 19.0 and 25.0 mm NMAS). The differences are likely attributed to the differences in the optimum binder content, VMA and RAP content.

Figure 3 CTindex of Reheated Plant Mix Specimens

The difference in CTindex within a mix type is also significant. As an example, the lowest average CTindex of multiple replicates for SMA is 75 while the highest average is 224, which is approximately three times higher than the lowest average. This suggests that the volumetric requirements in the current specifications for mix design approval and acceptance testing are not sufficient to ensure that the mixtures within a mix type are produced with similar resistance to cracking.

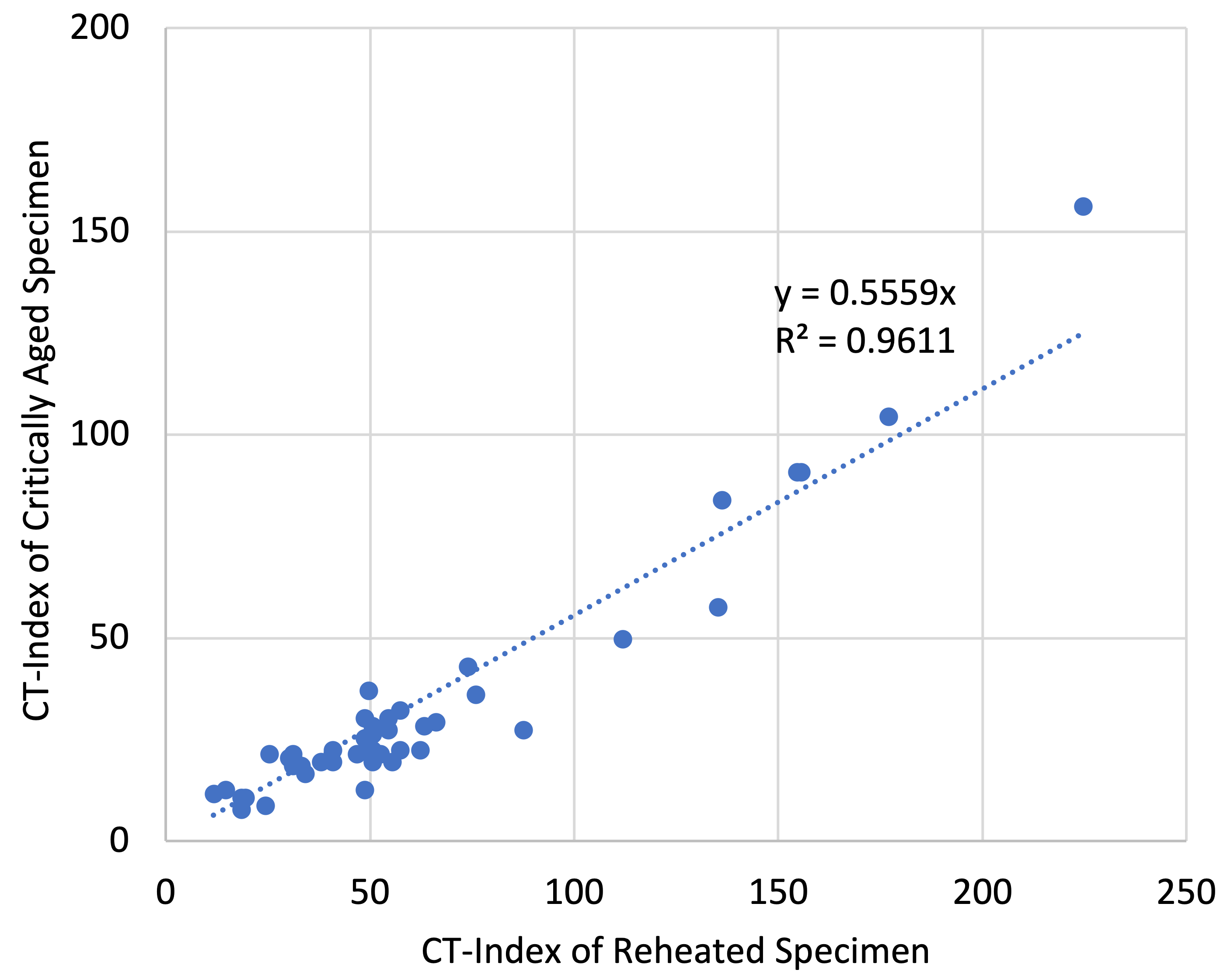

While the effect of critical aging is different from one mix to another, the CTindex of a critically aged plant mixture is approximately 45% lower than that of the reheated plant mix, as shown in Figure 4.

Figure 4 Effect of Critical Aging on CTindex of Reheated Plant Mix Specimens

Summary

With the implementation of the COAC approach for asphalt mix design, GDOT has seen improvement in the durability of asphalt mixtures produced with RAP. The results of this study suggest that RAP mixtures produced with the 60:40 COAC implemented in 2019 can have an equivalent or better CTindex than corresponding virgin mixtures while maintaining satisfactory rutting resistance. However, the difference in CTindex is still significant within each mix type designed and accepted based on the current specifications, potentially increasing GDOT’s risk of accepting asphalt mixtures with undesirable cracking resistance. Therefore, future adoption of an implementable cracking test for a balanced mix design approach in conjunction with the COAC approach can help ensure that asphalt mixtures produced with RAP in Georgia will have more consistent durability and cracking resistance, leading to more balanced performance in the field.

For more information about this article, please contact Nam Tran.