Perpetual Pavement Design Gets an Upgrade

Perpetual pavements are long-life asphalt pavements designed to perform longer than 50 years with minimal maintenance. A perpetual pavement requires only periodic mill and inlay of the top layer to maintain an excellent riding surface. Many successful perpetual pavements have been built in the United States, and in 2001, the Asphalt Pavement Alliance instituted the Perpetual Pavement Award program to recognize those long lasting roadways.

Perpetual pavement structural design relies on controlling the bending strain at the bottom of the asphalt concrete (AC) to prevent bottom-up fatigue cracking and vertical compressive strain deeper in the structure to prevent rutting of non-AC layers. The computer program, PerRoad, was initially created to enable designers to consider these critical locations in the pavement cross-section and choose appropriate thicknesses and materials needed to achieve a perpetual pavement. PerRoad was first released in 2003 and a major update was completed in 2010 with the release of Version 3.5. These early versions relied on single threshold values that had the potential to produce overly conservative perpetual designs. If a designer then wanted to compare the results with mechanistic-empirical (M-E) design that predicts pavement failure, separate design calculations had to be used. In some cases, a small increase in AC thickness or other layer inputs result in a perpetual pavement, so it is a good practice to compare the results, especially if a life cycle cost analysis is also being conducted.

New criteria recommended in recent research at NCAT have shown to yield more optimal perpetual pavement cross-sections consistent with those found in the Perpetual Pavement Award winners and those at the NCAT Test Track (NCAT Report 15-05). The new criteria focus on controlling the tensile strain distribution, rather than a single value, at the bottom of the AC to avoid bottom-up fatigue, and a single compressive strain percentile at the top of subgrade to mitigate non-AC rutting.

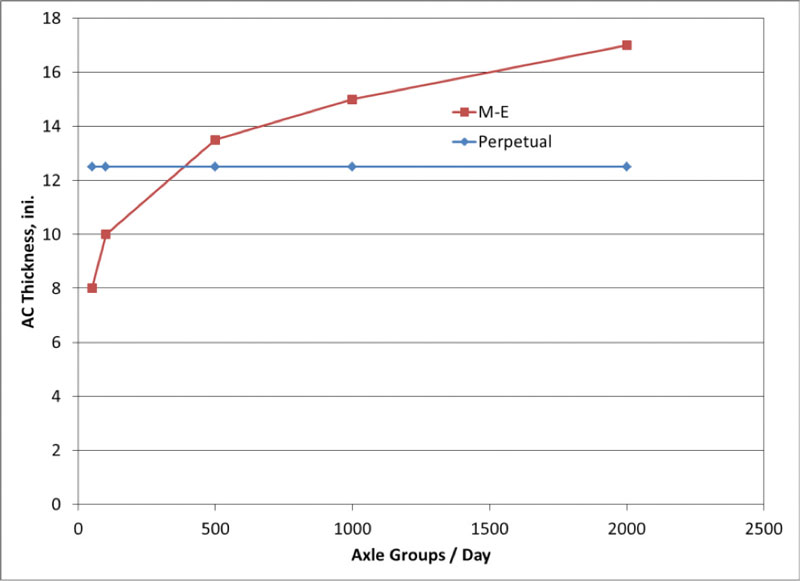

PerRoad 4.4 was redesigned to implement the new criteria and enable designers to execute conventional M-E designs within PerRoad to compare pavement cross-sections during the design phase. The new release of the software also allows the designer to select default strain distributions based on previous studies or enter a laboratory-determined fatigue endurance limit that the program will use to compute a control strain distribution. Figure 1 shows an example where a particular pavement becomes perpetual at 12.5 inches regardless of the traffic volume (axles/day). The M-E curve shows how the conventional design requires increasing pavement thickness with increasing traffic volume, with no upper limit. After about 400 axle groups/day, the conventional M-E design is over-designed for this set of conditions. At less than 400 axle groups/day, the designer could evaluate the additional thickness (and cost) required to achieve perpetual status and how best to proceed.

Figure 1: Conventional M-E versus Perpetual Design

The design analysis results within PerRoad 4.4 are presented in a pass/fail format. If the pavement fails to meet the criteria or is overly conservative, then the structure can be adjusted accordingly. In addition to the input and output updates, the software was also enhanced to provide an Excel© output formatted ready-to-print. These reports may be used when developing a pavement design project and document all inputs and outputs developed in the design process. PerRoad Version 4.4 can be downloaded free of charge at http://www.asphaltroads.org/perpetual-pavement/about-perpetual-pavements/.