Can Local Aggregates Provide Enough Friction?

High friction surface treatments (HFST) provide enhanced pavement friction in critical safety locations such as horizontal curves and bridge decks. HFSTs are a thin layer of durable, high friction aggregate bonded to an existing pavement surface using a liquid polymer resin binder. The resulting surface is extremely rough and polish-resistant, providing long-lasting skid resistance in locations where tire-pavement friction is paramount.

Calcined bauxite is the only aggregate that currently meets the friction performance requirements for HFSTs per AASHTO specification PP 79-14 Standard Practice for High Friction Surface Treatment for Asphalt and Concrete Pavements. Since calcined bauxite must be imported from overseas, it is costly. Some states, including Michigan, also have specifications for thin polymer-bonded overlays, which have been used as bridge deck treatments for many years and often allow the use of less-expensive, regionally available friction aggregate. In this article, the term HFST is used broadly to include any thin bonded surface treatment that increases the friction capability of a pavement surface.

Michigan DOT recently sponsored an evaluation of 11 friction aggregates, detailed in NCAT Report 17-01, using NCAT’s Three Wheel Polishing Device (TWPD). This laboratory method applies uniformly controlled conditioning (polishing) in the TWPD followed by testing with the dynamic friction tester (DFT) and the circular texture meter (CTM). This procedure allows engineers to make relative comparisons of friction aggregate performance while agencies retain the responsibility to determine an acceptable friction threshold value.

In addition to calcined bauxite, the study included a basalt and copper slag from Wisconsin, flint from Oklahoma, three varieties of calcined kaolin from Georgia, three varieties of quartz (from Ohio, Washington, and Maryland), and feldspar mineral from Wyoming. Two replicates were made for each aggregate. The surface of each 20x20-inch asphalt test slab was covered with an epoxy bonding agent (E-BOND 526) at a rate of 0.04 gal/sq ft, and the aggregate was spread by hand over the epoxy. After curing for 24 hours, the surface was swept, rubbed with a wooden board to remove loosely bound aggregate, and swept again.

The two replicate slabs for each aggregate were conditioned using the TWPD units. The TWPD operates at a speed of 60 rpm, uniformly polishing a circular path 284 mm in diameter on each test surface. All three pneumatic tires on the TWPD that performed the polishing were replaced for each slab. Previous studies have shown that terminal surface friction is reached between 80,000 and 100,000 cycles, but this study extended testing to a total of 140,000 (140K) cycles in order to better distinguish between higher performing aggregates.

Each slab was tested using the CTM (according to ASTM E 2157) and DFT (according to ASTM E 1911). The CTM measures surface macrotexture in terms of mean texture depth (MTD). The DFT measures surface friction as a function of speed (20, 40, and 60 km/h for this study). The result is a dimensionless value known as the friction number (Fn). In this study, 40 km/h produced the most repeatable results, so the friction values are expressed as DFT(40). Higher values indicate better friction properties. The testing sequence involved initial CTM and DFT measurements on each slab followed by TWPD conditioning for 70K cycles. After drying overnight, each slab was tested again using the CTM and DFT. Additional TWPD conditioning of 70K cycles was performed, and final CTM and DFT measurements were taken after the slabs dried overnight.

The difference between DFT measurements for replicate slabs was evaluated for similarity. The average difference in DFT(40) for replicate slabs was 0.034. Only three differences were greater than two standard deviations from the mean (0.08), and they represent initial DFT measurements not critical to the analysis. More than 60% of the differences in DFT(40) between replicates were less than 0.040, which is similar to the results of an earlier study (NCAT Report 15-04). The CTM data were very repeatable, so no quality control evaluation was needed.

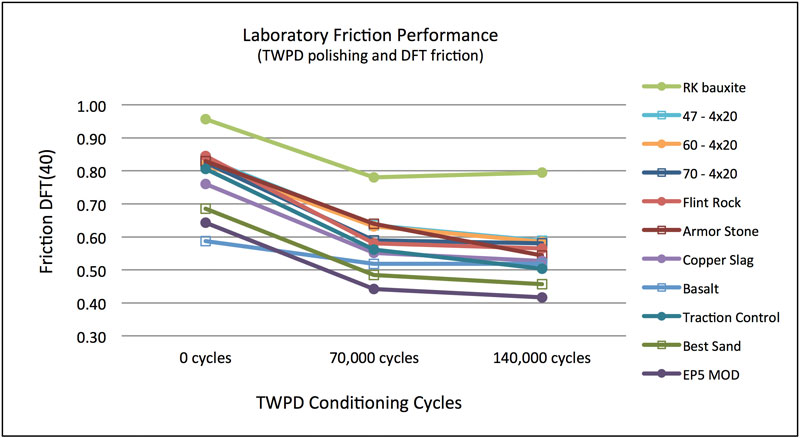

Figure 1 shows the DFT friction values measured at 40 km/h (DFT(40)) for each aggregate tested. The legend ranks the aggregates from highest to lowest DFT(40) values after 140K TWPD polishing cycles. Calcined bauxite maintained higher friction performance than the other aggregates tested. All three calcined kaolin products (47 – 4x20, 60 – 4x20, and 70 – 4x20), as well as the OK flint, had similar high performance compared to the remainder of the other aggregates. The WA quartz (Armor Stone) continued to polish between 70K and 140K cycles, so its terminal friction placed it in a middle performance category along with the WI copper slag and WY feldspar (Traction Control). The WI basalt had the lowest initial DFT(40) value but showed good polish resistance with minimal friction loss after 140K polishing cycles. The quartz aggregates from Ohio (Best Sand) and Maryland (EP5 MOD) exhibited the lowest friction performance.

Figure 1: Comparison of Laboratory Friction Performance

Figure 2 shows the CTM macrotexture measurements for each aggregate tested. After 140K TWPD cycles, all MTD measurements were in the in range of 1.2 to 1.8 mm, which is typical for HFSTs after conditioning. By comparison, terminal macrotexture values are typically less than 1.2 mm for porous asphalt mixes and less than 0.60 mm for dense-graded asphalt mixes. As noted in previous HFST studies, measured friction and surface macrotexture had no correlation.

Figure 2: Comparison of Laboratory Surface Texture Performance

A previous FHWA-sponsored study comparing laboratory TWPD conditioning and test sections at the Test Track showed that laboratory DFT terminal friction values are higher than field terminal friction values measured using a locked-wheel skid trailer, ASTM E 274. Based on the correlation developed in that study (NCAT Report 15-04), the calcined kaolin products and flint would be expected to have a terminal friction value of approximately 40 (SN40R) using a skid trailer.

For the eleven aggregates selected by Michigan DOT, measured DFT(40) values ranged from 0.40 to 0.80. This wide range indicates substantial differences in friction performance among the various aggregates. It is the governing agency’s responsibility to set acceptable thresholds for friction aggregate performance. Depending on site-specific factors, regionally available friction aggregate may be appropriate for some applications. The success of locally placed sections, measured in terms of crash reduction, is one approach to developing acceptable friction thresholds.

HFSTs do not extend pavement life and should not be applied to existing pavements in poor condition. Further, conventional pavement preservation techniques do not provide the same level of friction as HFSTs. Ongoing work at the NCAT Test Track is evaluating higher friction preservation treatments using calcined bauxite as an aggregate. Section W7A, placed in 2015, has a 0.25-inch microsurface treatment with 50% bauxite. Section W3, a 0.75-inch thinlay stone matrix asphalt (SMA) with bauxite and granite, was placed in the spring of 2017.

W7A has a friction value of 55 (SN40R) after eight million equivalent single axle loads (ESALs) of traffic. By comparison, the HFST with bauxite (section W8B) has a friction value of 60 after 20 million ESALs. Although W7A has lower friction than the bauxite HFST, it is still very good. Further trafficking will determine whether the bauxite microsurfacing continues to maintain good friction over time. W3 only had three million ESALs applied at the time of these friction measurements. Initially, friction was lower at 44 (SN40R) due to the asphalt surface film. This film has been worn off by traffic, and the friction values are currently comparable to W7A.

CTM macrotexture measurements are very good (near 1.00 mm) for the bauxite HFST (W8B). W7A has good macrotexture (0.75 mm), but W3 is less than 0.40 mm. Although W7A and W3 have similar friction at this time, bauxite micro-surfacing (W7A) may be a better safety surface based on its higher macrotexture, which reduces hydroplaning potential. With crash reduction in mind, researchers continue to evaluate surface friction performance to better understand what levels of macrotexture and friction are sufficient to provide safe pavement surfaces.