- Spring 2019

Development of a New Accelerated Lab Friction Testing Standard

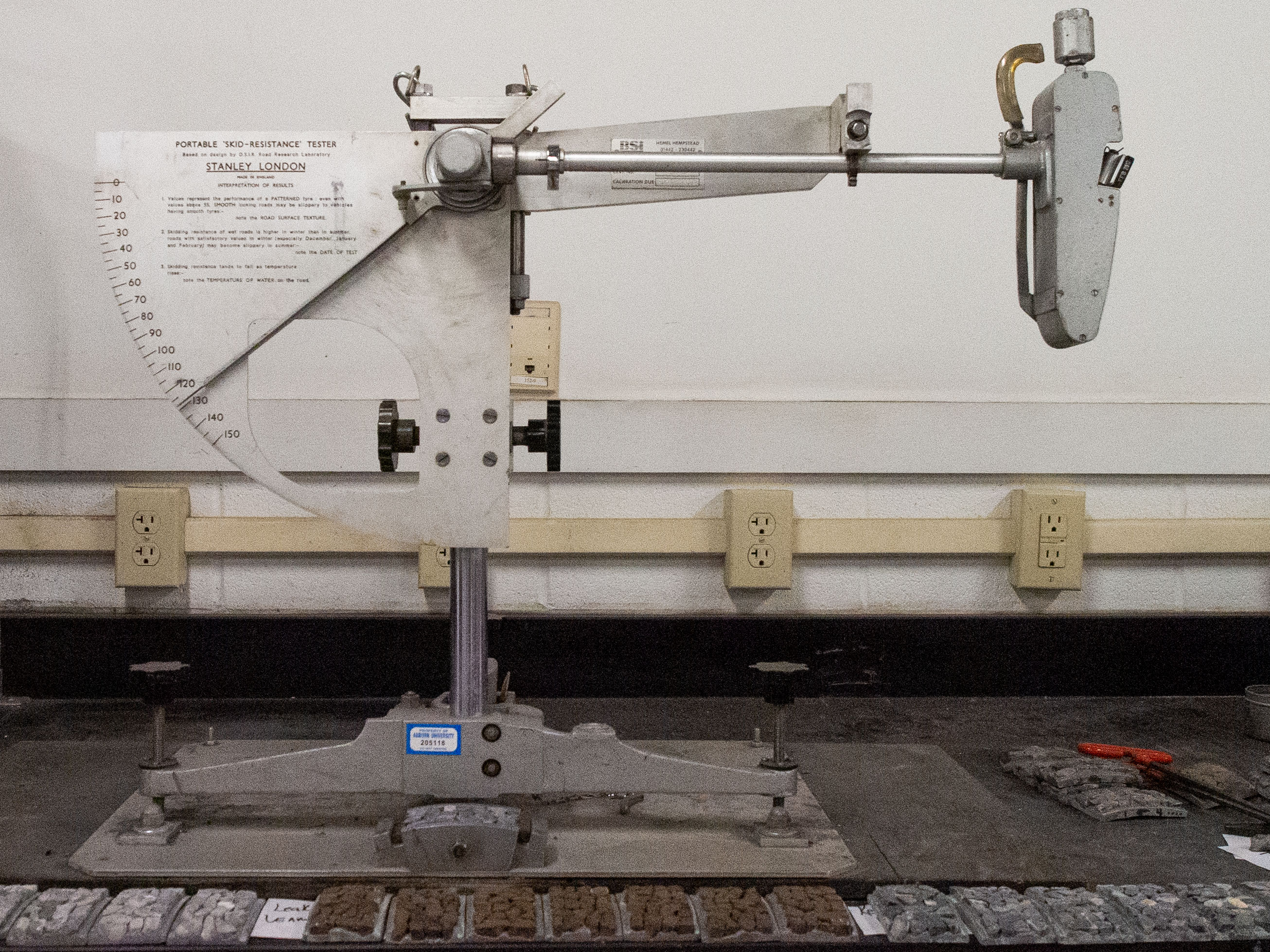

British Pendulum Tester

Some highway agencies still rely on the British Pendulum (BP) test to qualify aggregates for asphalt pavement surface friction. Other agencies specify friction aggregate based on geology and/or mineralogy. Both approaches have allowed agencies to maintain an acceptable level of pavement friction long-term performance. However, the BP polishing and testing procedure evaluates a single size coarse aggregate and requires careful manual adjustment of the pendulum height to obtain the correct length of surface contact. Recent advances in laboratory polishing and friction testing now provide a better assessment of friction that considers the entire gradation in an asphalt mixture rather than a single aggregate source.

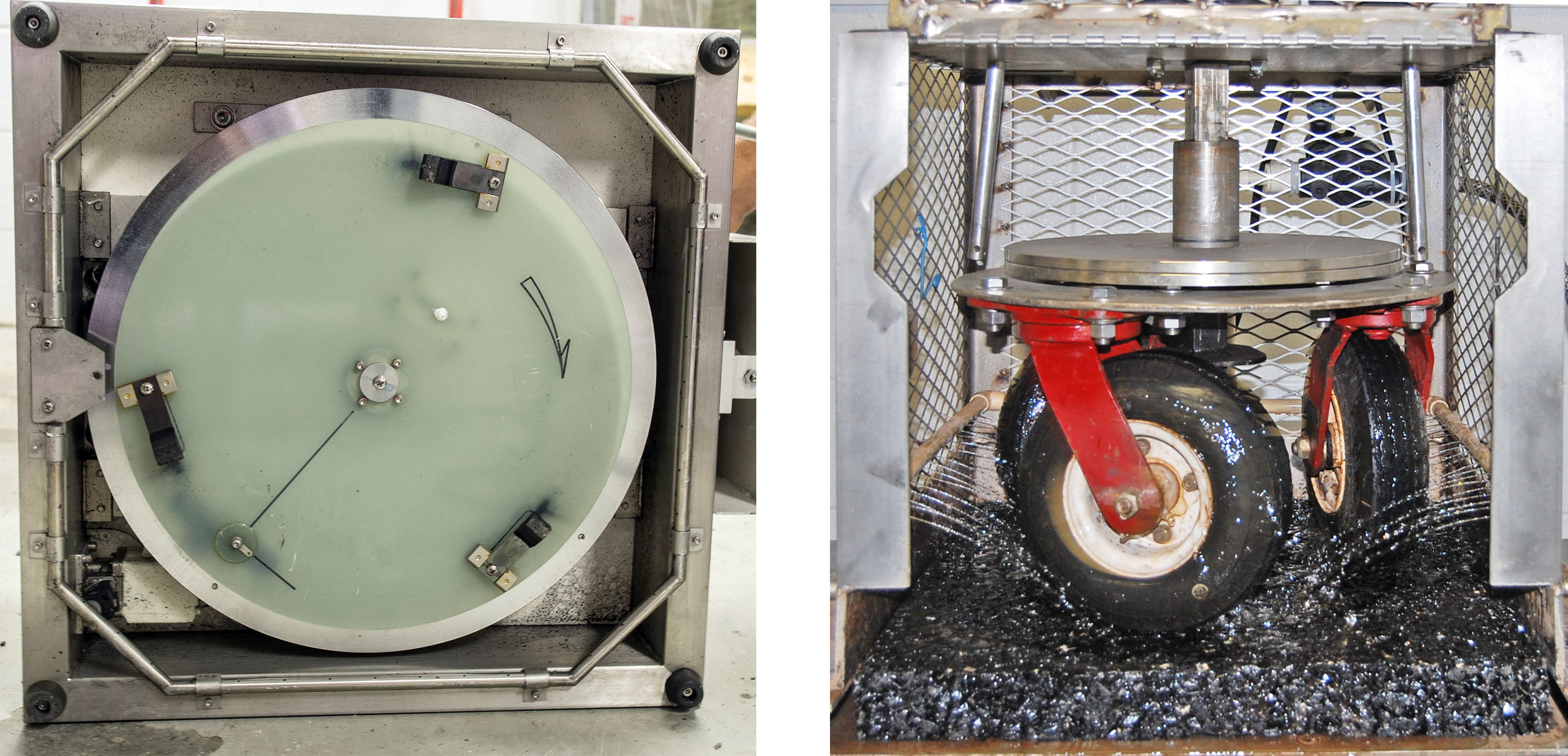

The Dynamic Friction Tester (DFT) gives a better assessment of the friction of a pavement surface. The DFT procedure, standardized in ASTM E1911, provides a more consistent measurement (no manual adjustment of the device before testing) and records friction over a range of speeds. NCAT developed the Three Wheel Polishing Device (TWPD) in 2006 to complement the DFT for measuring friction on asphalt mixtures.

The Maryland State Highway Administration modified the TWPD concept to use a large ring of a single aggregate on an epoxy substrate. After polishing with the TWPD, the ring of aggregate can be tested with the DFT to assess the aggregate’s terminal friction value. Under Maryland’s lead, a task group of AASHTO agency representatives and NCAT researchers are developing a new standard test procedure utilizing the TWPD and DFT. This standard will provide equipment requirements and testing procedures to rapidly evaluate an aggregate source or asphalt surface mixture for long-term friction performance. In addition to the TWPD and DFT, the equipment includes an aggregate specimen preparation device consisting of a rigid mold for the single aggregate procedure. The mixture specimen preparation procedure will permit any slab compaction procedure that produces the required size with a smooth surface compacted to a uniform target density. The testing procedure for aggregate polishing and asphalt mixture polishing are slightly different but involve the same TWPD. Both procedures use the DFT for measuring friction.

Dynamic Friction Tester (left) and NCAT Three Wheel Polishing Device (right)

This new friction testing protocol allows an agency or aggregate supplier to determine the long term (terminal) friction properties of any aggregate or asphalt mixture in about one week for a cost of less than $5000. A few agencies have used this system to assess the friction performance of aggregate blends for surface mixtures at a substantially lower cost and much shorter time period compared to full-scale field test sections with no risk to the traveling public. Contact NCAT Lab Manager Jason Moore for more details and a quote from our lab for testing your mixture.

For more information about this article, please contact Michael Heitzman.