- Spring 2019

Evaluation of Rejuvenating Fog Seals

Delta Mist TM rejuvenator is applied to Section S3 of the NCAT Test Track.

A rejuvenating fog seal is a type of pavement preservation treatment applied to an existing asphalt pavement surface to preserve its functional and structural integrity and delay a more costly rehabilitation treatment in the near future.

A fog seal consists of a slow setting asphalt emulsion (e.g., SS-1, SS-1h, CSS-1 and CSS-1h) diluted with one to four equal parts of water and applied at rates between 0.06 - 0.13 gal/yd 2 on an existing pavement surface without a cover aggregate. It is intended to penetrate into the surface pores of the pavement to seal very small cracks and surface voids as well as coat surface aggregate particles. Pavement surfaces with high void contents are more susceptible to oxidative aging due to greater exposure of the binder to air and higher temperatures. The asphalt binder becomes stiffer, and consequently, more brittle through oxidation, leading to deterioration.

Rejuvenators can be added to fog seals to treat raveled and aged pavements by improving penetration into the pavement and improve the flexibility of the aged binder. Rejuvenators are petroleum or bio-based oils with chemical and physical characteristics selected to restore properties of the aged asphalt binder in the surface layer. Adding a rejuvenator to a fog seal reduces the likelihood of cohesive failure within the asphalt binder film and can slow the rate of aging caused by oxidation. For optimal restoration of the aged asphalt binder, consideration should be given to the chemical composition of the rejuvenator rather than just its capacity to reduce the viscosity of the aged binder. Furthermore, the degree of diffusion of the rejuvenator into the aged binder is of utmost importance since it allows chemical changes to take place that affect the physical properties.

Although rejuvenators can be categorized based on the material source or manufacturing process (i.e., aromatic oils, naphthenic oils, paraffinic oils, tall oils and fatty acids), it is also important to differentiate among products based on their chemical fractions. The composition of an asphalt binder is often defined by its so-called SARA fractions: saturates (S), aromatics (A), resins (R), and asphaltenes (A), which have increasing molecular polarity (saturates have the lowest and asphaltenes the highest). Often, asphalt is described as a colloid that consists of dispersion of asphaltenes in an oily matrix constituted by saturates, aromatics, and resins. Asphaltenes are stabilized in crude oils by natural resins, which are surfactant-like agents.

- Rejuvenators that are most compatible with the aromatics of the asphalt binder will reduce the viscosity and modulus of the asphalt binder through lowering the viscosity of the continuous solvent phase.

- Rejuvenators that have affinity for various fractions of the asphalt binder will reduce the viscosity of the binder through restoration of the original binder asphaltenes to maltenes ratio (i.e., the asphalt chemical fractions).

- Rejuvenators that exhibit low compatibility with the aromatics, asphaltenes and resins fractions of the asphalt binder, due to the presence of paraffinic and saturated materials with high crystalline fractions, will reduce the modulus of the binder. However, with aging, these components can increase the colloidal instability of the asphalt binder resulting in the precipitation of the asphaltenes.

An important factor when considering rejuvenating fog seals is the fact that these products will immediately decrease the skid resistance of the pavement. Rejuvenating seals should be selected as a treatment for pavements that have age-related distresses associated with stiffening of the asphalt binder. The curing time of a rejuvenating fog seal product, and its effect on friction, is influenced by the application rate, the existing pavement surface condition, and weather conditions at the time of the application. Therefore, traffic control and temporary reduced speed limits are often necessary after application for safety and to protect the integrity of the applied treatment.

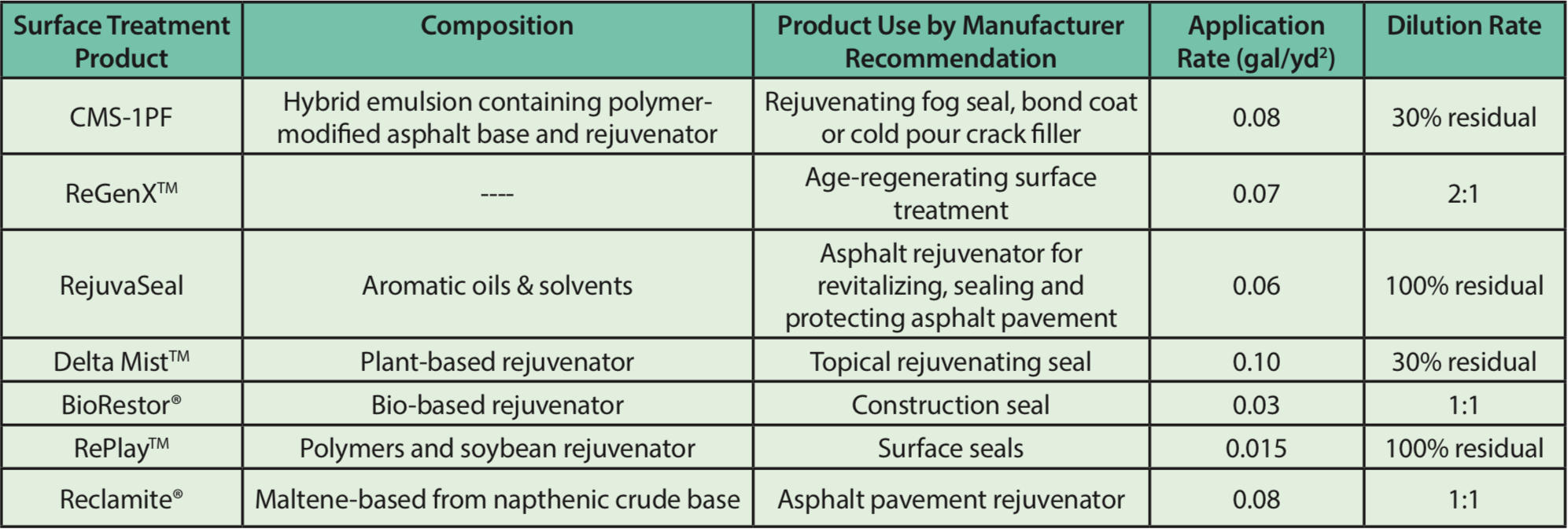

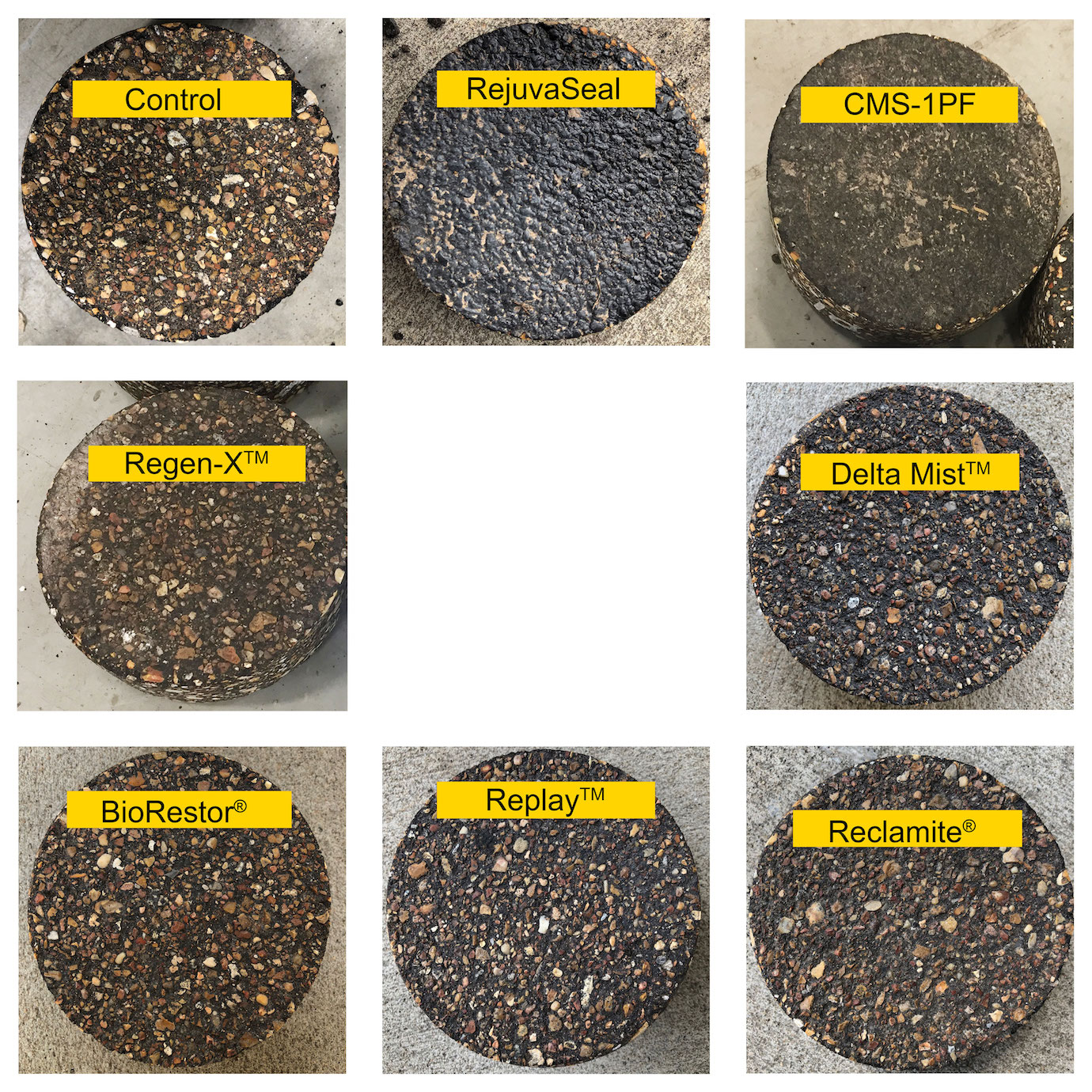

As part of the current research cycle at the NCAT Test Track, the Mississippi and Tennessee Departments of Transportation have both sponsored rejuvenating seal experiments. NCAT conducted a preliminary screening study to evaluate seven rejuvenating seals to determine which products would be used on the Test Track sections (Table 1). The products were applied over an asphalt surface layer (asphalt content = 6.8%) with a mix of gravel aggregate constructed for the Test Track in 2012.

Table 1. Rejuvenating products used on the NCAT screening study.

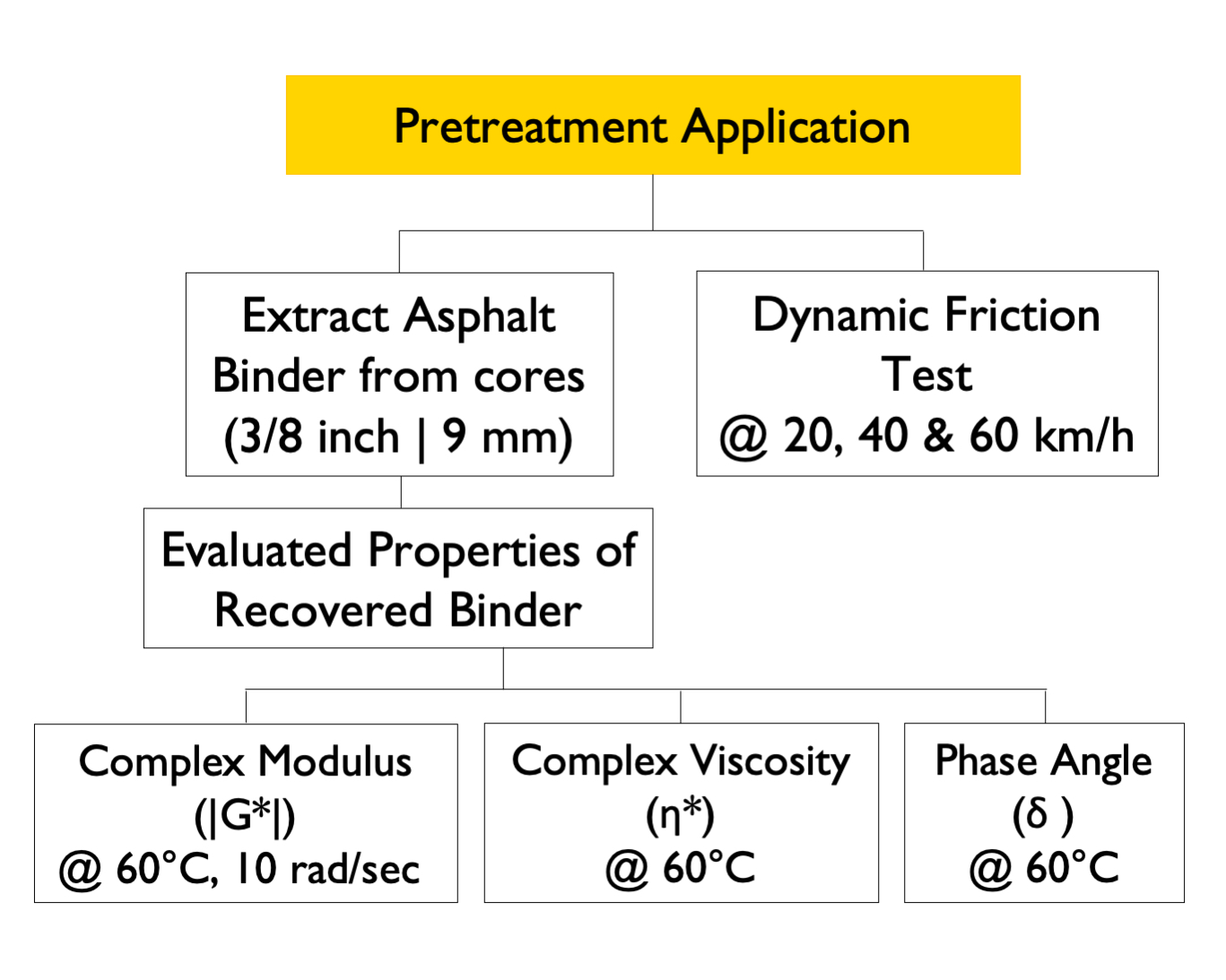

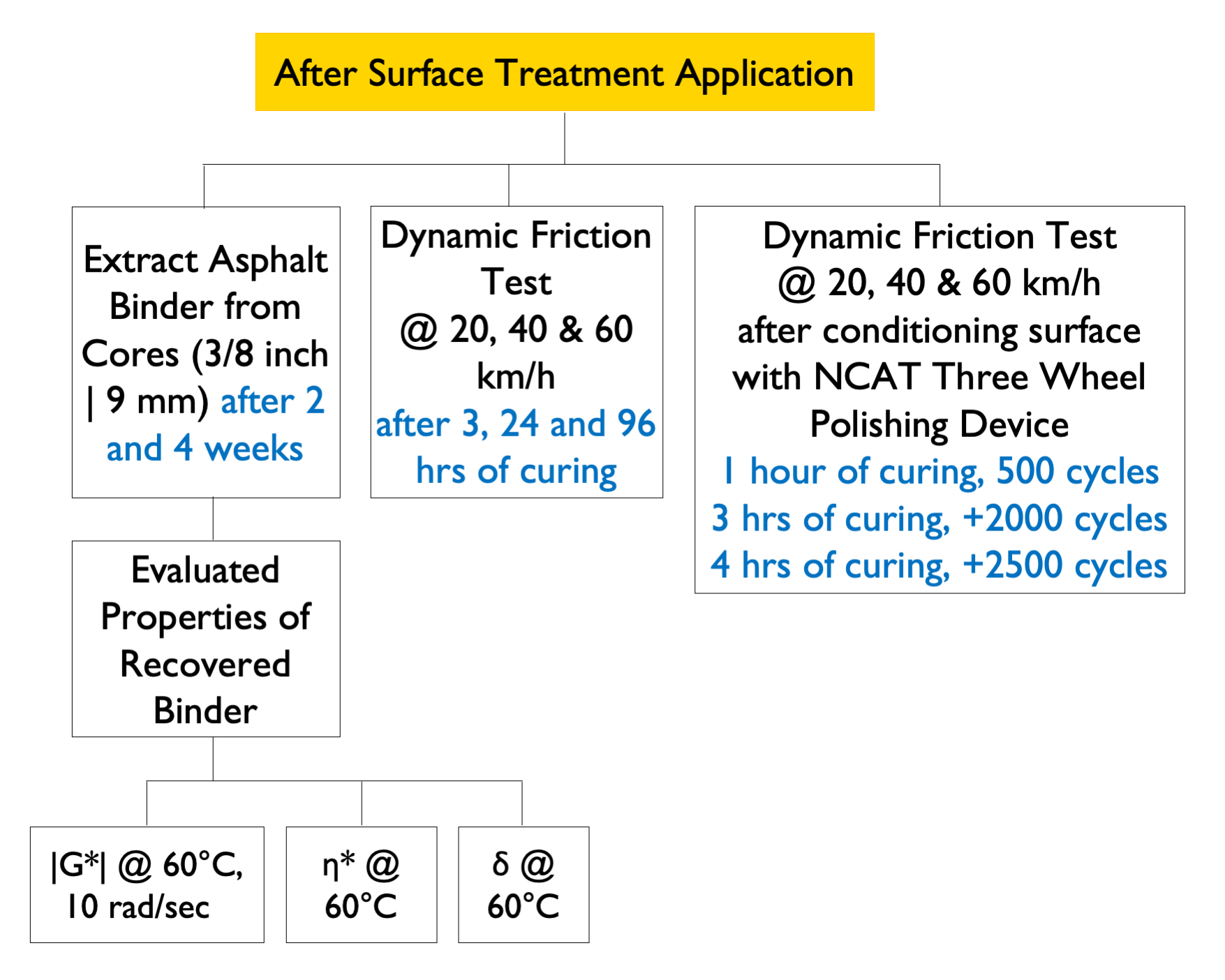

A modification of the Federal Aviation Administration’s procedure P-632 (Bituminous Pavement Rejuvenation) was used to evaluate the rheological properties of the extracted binders two and four weeks after the application of the seven products. A schematic of the testing matrix utilized in this study before and after the application of the rejuvenating seal products is shown in Figures 1 and 2, respectively.

Pavement surface friction characteristics collected with the Dynamic Friction Tester 3, 24, and 96 hours after the applications of each treatment were also used in the screening process. Furthermore, friction tests after traffic simulated with the NCAT Three Wheel Polishing Device were also conducted.

Figure 1. Testing matrix performed before application of the rejuvenating seal products.

Figure 2. Testing matrix performed after application of the rejuvenating seal products.

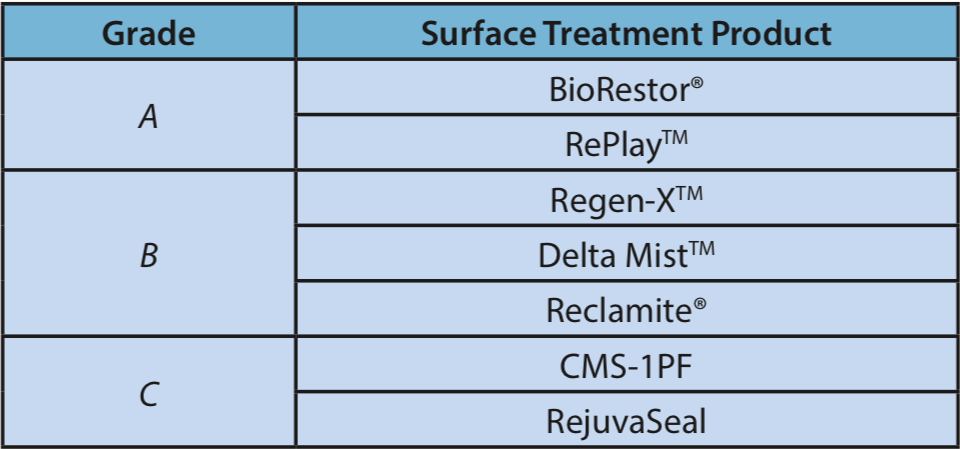

The seven rejuvenating seal products were ranked based on their rheological properties and friction test results (Table 2). It is important to mention that this classification was based on testing of each product applied to only one pavement surface (i.e., one base binder, one aggregate type, and one mixture design). Different base binders, aggregates, and mix designs could potentially alter this classification. The results were presented to MDOT and TDOT to assist in the decision-making process for which rejuvenating seal products to use on their respective test sections. The Mississippi DOT selected ReGenX TM and Delta Mist TM to be evaluated on its S3 Test Track section. The Tennessee DOT selected Reclamite ® and an experimental product, e-Fog S, to be evaluated on its S4 Test Track section. The field performance of these four rejuvenating fog seals will be evaluated for the entire two-year Test Track cycle as well as a more complete assessment of their effects on friction and rheological properties of the binders recovered from the top 9 mm of the pavement surfaces.

Table 2. Performance-based classification of rejuvenating products.

From this study, three important observations were made:

- Both dilution and application rates play a role in the effectiveness of the surface treatment in restoring the rheological properties of the aged binder. Rejuvenating seals with lower dilution ratios and higher application rates showed higher restoration of the binder rheological properties over the long-term.

- For asphalt surfaces more than three years old, the complex modulus, |G*| (i.e., the stiffness) and complex viscosity of the binder extracted four weeks after the rejuvenating seal application must decrease by at least 40% from the pretreated values in order to maintain the effectiveness of the surface treatment.

- To ensure safety, the coefficient of friction of the existing pavement surface should be measured before the rejuvenating seal treatment is applied. After three hours of curing, friction values similar to those prior to application should be obtained. After four days of curing, the rejuvenating seal should have no adverse effects on friction.

In summary, rejuvenating fog seals are a low-cost option for preventing or retarding the surface deterioration of pavements, practical in use since they do not require specialized equipment, and can be effective for restoring the surface condition of an existing pavement.

Surface of extracted cores from the NCAT preliminary study four weeks after application of the rejuvenating fog seal treatment.

For more information about this article, please contact Raquel Moraes.