- Fall 2021

Which Cracking Test? NCAT's Test Track Provides Answers.

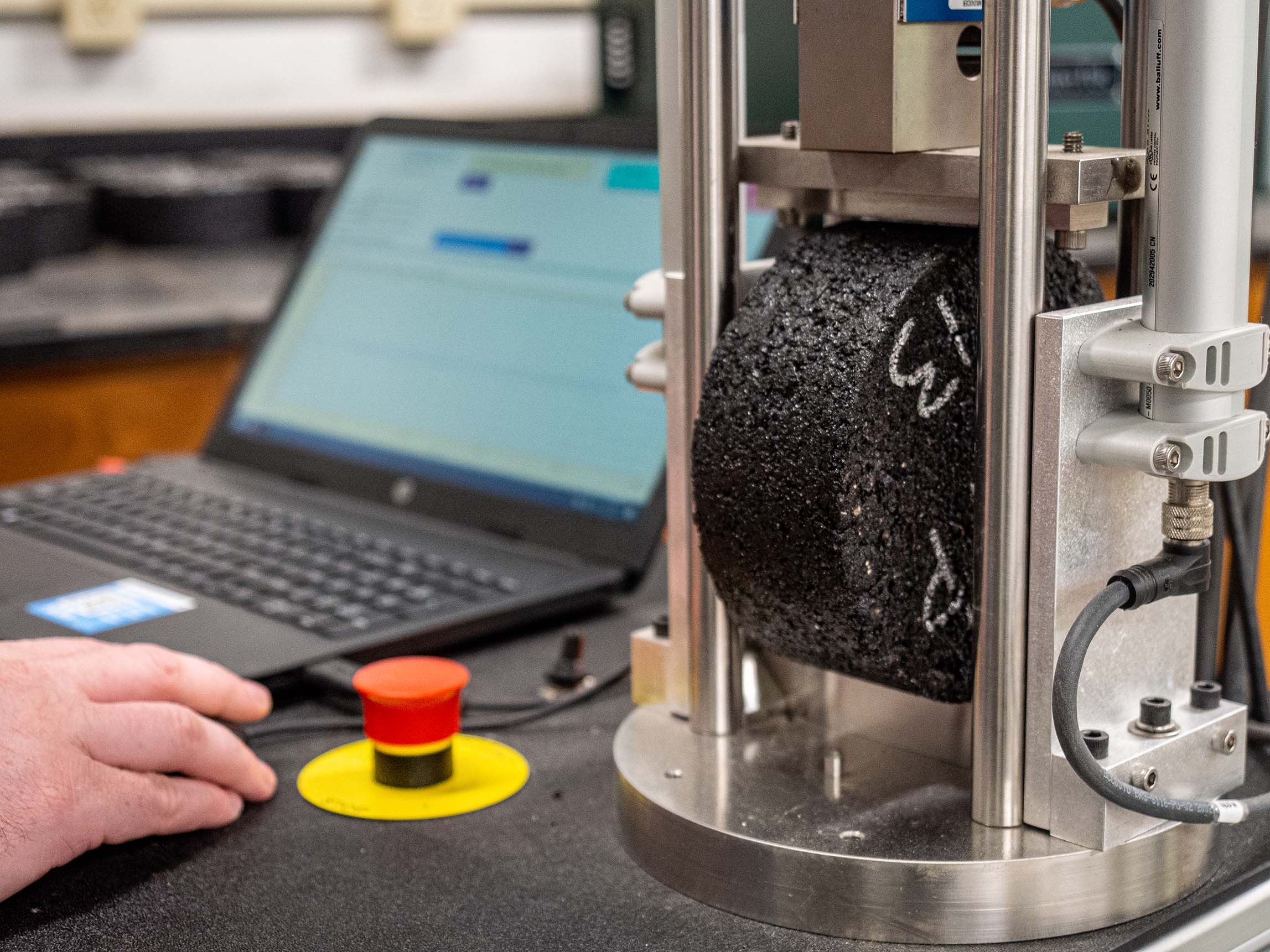

The Indirect Tensile Asphalt Cracking Test (IDEAL-CT) can determine the cracking potential of asphalt mixtures.

Most state DOTs and contractors now agree that changes are needed in the way that we conduct and approve asphalt mix designs and measure mixture quality during pavement construction. A new era is dawning on the process for asphalt mix design and quality assurance testing based on balanced mix design (BMD), centered around simple mechanical tests that provide better indications of how a mix can resist the most common forms of distress. Most stakeholders recognize the limitations and deficiencies of the current system based on volumetric properties. In retrospect, the Superpave mix design system was supposed to include mixture performance tests for moderate and high traffic roadways; however, those performance tests were not practical for routine use.

The first mountain to climb on the path toward BMD implementation has been to decide which tests to use. Over the past several decades, numerous rutting, cracking, and moisture damage tests have been proposed by researchers. However, most of the tests have lacked field performance validation with no consensus on which tests are suitable for day-to-day usage.

In 2015, NCAT launched a new experiment on the Test Track to provide correlations between top-down cracking and results from several of the most promising cracking tests. That study, known as the Cracking Group experiment, was funded by the FHWA and DOTs in Alabama, Florida, Illinois, Maryland, Michigan, Minnesota, Mississippi, New York, North Carolina, Oklahoma, and Wisconsin. The experiment included seven test sections built with the same pavement structure but with differing surface mixes, including mixtures that were expected to have cracking resistances ranging from poor to very good. Even with the pounding loads on the Test Track, it took over four years to develop a meaningful spread in the amount of cracking among the seven test sections.

Aging of surface layers is a critical factor in the development of top-down cracking. As part of this study, NCAT developed a “critical-aging” protocol to simulate the four to five years of in-service aging of surface layers. The term critical aging was coined to differentiate it from long-term aging. The goal of the critical aging protocol is to age mixtures in the lab just to the point where top-down cracking typically begins to appear in pavements. The critical aging protocol for Alabama conditions is aging of loose mix spread out in a pan at a depth of no more than ½” for eight hours at 135°C.

Seven laboratory cracking tests were selected for evaluation by the sponsors for the experiment. Conducting the cracking tests on all of the same mixes at the same time provided an easy way to compare other concerns such as testing time, variability, and complexity, which are important considerations for tests to be used in day-to-day practice. Based on the results of the NCAT top-down cracking experiment, the following findings and recommendations were provided.

IDEAL cracking test (IDEAL-CT): The CTIndex from the IDEAL-CT method is a very good indicator of top-down cracking resistance. It has strong correlations to the field performance of the NCAT test sections and the results are statistically discernable from mix to mix. For critically-aged samples, a minimum CTIndex of 15.0 was found to be a good criteria for top-down cracking based on the data. However, CTIndex results are affected by specimen air void contents in an incorrect manner. Specimens with lower air voids have lower CTIndex results, which is counter to the field cracking performance as evidenced by the test sections on the track. Until this issue is corrected, the test should only be conducted on specimens compacted to 7.0±0.5%. The IDEAL-CT method is the most practical of the evaluated cracking tests and is well suited for everyday use in BMD and quality assurance testing.

Illinois flexibility index test (I-FIT): The flexibility index from the I-FIT procedure correlated well with top-down cracking observed for the test sections. However, due to higher variability of FI for several mixtures, the critically aged plant mix results were not statistically distinguishable among some good and moderately performing mixtures or between good and poor performing mixtures. A disadvantage of the I-FIT is the time and cost of preparing specimens, which includes cutting and notching of the semi-circular test specimens. Also, like CTIndex, FI results are affected by specimen air void contents in an incorrect manner.

Texas overlay test (OT-TX): The cracking progression rate (CPR, also referred to as the β parameter) from the OT-TX test is a very good indicator of a mixture’s resistance to top-down cracking. It is a much more discerning cracking indicator than the traditional OT criteria of “cycles to failure”. For OT-TX tests on critically-aged mixtures, a CPR value of 1.75 separated mixtures with moderate top-down cracking resistance from mixtures with very good performance. However, the OT-TX test is not practical for day-to-day use in BMD and quality assurance testing due to the time required to prepare specimens and the cost of the equipment.

NCAT modified overlay test (OT-NCAT): The NCAT-modified version of the overlay test is also a very good indicator of resistance to top-down cracking. A CPR value of 0.37 is recommended as a preliminary criterion for critically-aged mixtures based on the plant mix results of this experiment. The NCAT-OT has a lower coefficient of variation than the OT-TX procedure and the testing time is faster. However, like the OT-TX, the test lacks practicality due to the time of preparing specimens and high equipment cost.

Louisiana semi-circular bend test (SCB-LA): The Louisiana SCB test did not provide a suitable correlation with top-down cracking performance of the mixtures in this experiment. Two of the mixtures that performed very well on the track had results very similar to those of mixtures with moderate cracking. Other disadvantages of the SCB-LA are the time and cost of preparing notched semi-circular specimens, and that standard methods of variability analysis cannot be applied to the results.

Asphalt mixture performance tester (AMPT) cyclic fatigue test: The AMPT cyclic fatigue test index parameter, Sapp, correlated well with the observed top-down cracking for the test sections for this experiment. The results also support North Carolina State University’s recommended minimum Sapp criterion of 30 for short-term aged mixture samples for Very Heavy traffic pavement applications. However, the Sapp result for the best performing test section in the experiment was lower than expected. This may indicate that the cyclic fatigue test or its criteria need to be adjusted for asphalt-rubber mixtures. Disadvantages of this test are the time and cost to prepare specimens, cost of the equipment, and complexity of data analysis. For these reasons, it is not well suited for routine use in BMD or quality assurance testing.

Energy ratio (ER): Energy ratio results did not match field performance for top-down cracking. This test also lacks practicality for routine use due to its complexity and time to complete the three parts of the test, so it is not recommended for implementation.

Selecting tests for BMD is the first major step toward advancing asphalt mix design and quality assurance testing. Once implemented, BMD will result in improved pavement performance and open the door to innovations that cannot be adequately evaluated with Superpave binder and mix specifications.