- Fall 2019

Research Needed on Using Recycled Plastics in Asphalt

Over the last few years, there has been increasing interest in using recycled plastics in asphalt pavements. News outlets and social media reports have suggested that recycling plastics in asphalt mixtures is a golden opportunity to improve the performance of pavements while eliminating the growing amount of waste plastics being landfilled or polluting the environment through litter. According to the Environmental Protection Agency, approximately 33 million tons of plastics were generated in 2014, with less than 10% being recycled. Among the plastics generated, linear low-density polyethylene (LLDE), low-density polyethylene (LDPE), and high-density polyethylene (HDPE) combine to account for the largest proportion while other types of plastics include polyethene terephthalate (PET), polypropylene (PP), polyvinyl chloride (PVC), polyurethane (PU), polystyrene (PS), polycarbonate (PC), and others.

Using recycled plastics in asphalt is not a new concept. In general, there are two approaches to incorporating recycled plastics in asphalt mixtures: the wet process and the dry process. In the wet process, recycled plastics are added to the asphalt binder as with polymer modifiers, where mechanical mixing is required to achieve a homogenous plastics-modified binder blend. In the dry process, recycled plastics are added directly to the mixture either as a partial aggregate replacement or a mixture modifier. Unfortunately, both processes have implementation challenges. For the dry process, there is a concern about the lack of consistency in the quality of the final produced mixtures. For the wet process, a major limitation is poor storage stability of the plastic-modified binder, where the plastic tends to separate from the asphalt binder due to the difference in density and viscosity as well as the chemical incompatibility between the two components.

India reportedly has over 15 years of experience with the dry process for low volume roads. During mixture production, up to 10% of recycled plastics (limited to LDPE, HDPE, PU, and PET) by weight of asphalt binder are added, where the plastics are melted and coat the surface of the aggregates. Existing studies indicate that pre-coated aggregates with recycled plastics have enhanced toughness, abrasion resistance, bond strength, and reduced asphalt absorption, which produces asphalt mixtures with better resistance to rutting, fatigue damage, and moisture damage. Unfortunately, most of these studies lack a robust experimental plan and suffer from the use of dated test methods.

Over the last decade, several laboratory studies in Asia and Africa have reported successful experience with recycled plastics using the wet process. These studies claim that adding recycled plastics can significantly increase binder stiffness and rutting resistance, and thus, has the potential to extend the service lives of asphalt pavements. However, in the U.S., rutting is much less of a problem for most highway agencies; the greatest current challenge is cracking of some form or another. Because stiffer binders tend to be more susceptible to cracking, using plastics in asphalt may be more detrimental to performance.

In Europe, several demonstration projects have been constructed over the past few years using proprietary recycled plastic products in asphalt pavements. A limited number of research studies indicate that adding these plastic products improve the stiffness, rutting resistance, and fracture toughness of the modified asphalt mixtures while reducing the amount of asphalt binder by approximately 6-10%. Nevertheless, their impacts on the actual pavement performance remains unknown and warrants further investigation.

Earlier this year, Dow Chemical completed two small projects on private roads in Texas using asphalt binders modified with recycled plastics using the wet process. The binder formulation was a neat PG 64-22 binder modified with 1.5% LLDPE-rich post-consumer plastics, ElvaloyTM copolymer, and polyphosphoric acid. The final modified binder met the Texas Department of Transportation’s PG 70-22 specifications. More recently, the company worked with a contractor in Michigan to complete several parking lot and county road projects using similar binder formulations. Early field performance of these projects will be monitored in the next few years.

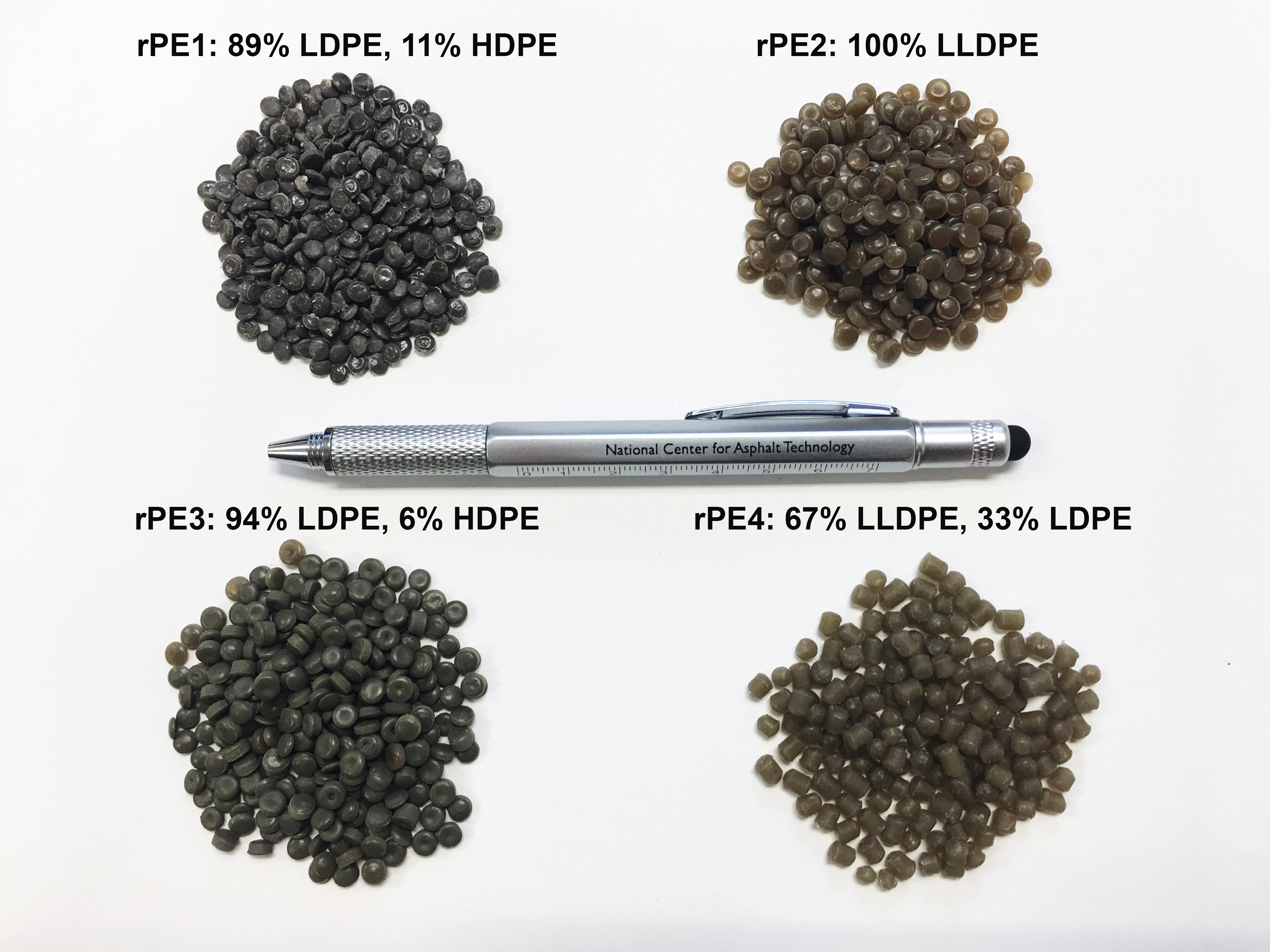

Since November 2018, NCAT researchers have been working on a study involving chemical characterization and performance testing of asphalt binders and mixtures modified with recycled polyethene (rPE) materials (Figure 1). The study is sponsored by the Plastics Industry Association. The very first experiment of the study focused on storage stability testing of rPE-modified binders. NCAT researchers found that when more than 3% rPE was used with the wet process, the modified binder failed the storage stability requirement due to separation of the rPE. However, adding a reactive ethylene-based terpolymer (RET) significantly improved the distribution and stability of rPE in the asphalt binder. The ongoing second experiment focuses on characterizing the rheological and chemical properties of rPE-modified binders. Preliminary results indicate that adding rPE increases the stiffness and rutting related parameters of asphalt binder but has no impact on its cracking related parameters. Using rPE and RET in combination, on the other hand, significantly improved binder elasticity and all rutting and fatigue parameters. Further, rPE modification improved the binder’s resistance to oxidative aging, but the improvement was less than with SBS modification. The last experiment of the study will focus on performance test evaluations of rPE-modified asphalt mixtures. A suite of mixture performance tests will be conducted to determine the effect of rPE modification on mixture rutting and cracking resistance. The study is anticipated to be completed later this year.

Figure 1. Recycled Polyethene (rPE) Samples used in the NCAT Study

There is no doubt that waste plastics are a global challenge, but our solution must avoid creating a bigger problem. Ideally, the solution will be a win-win, but it is apparent that it will require more research and development to prove the long-term value of using a new recycled material in the U.S. transportation infrastructure.

Despite the efforts discussed above, the development of the science of recycling waste plastics in asphalt is still at an early stage and needs much more research. Specifically, research efforts should be devoted to demonstrating that adding recycled plastics has no negative impact on the long-term performance, life-cycle costs, environmental impact, and recyclability of asphalt pavements or any unintended consequences on the health and safety of plant operators and construction crews. Furthermore, low-risk demonstration projects are needed to identify the potential changes in the production and construction practices of asphalt mixtures containing recycled plastics.

If all of the performance, environmental, and economic benefits can be proven, using recycled plastics in asphalt could be a sustainable solution. However, mandates for recycling plastics in pavements without a complete understanding of the impacts on pavement performance, the health of highway workers, and the environment could have devastating consequences.

For more information about this article, please contact Fan Yin.