- Spring 2017

Moving Towards Balanced Mix Design for Asphalt Mixtures

What is Balanced Mix Design?

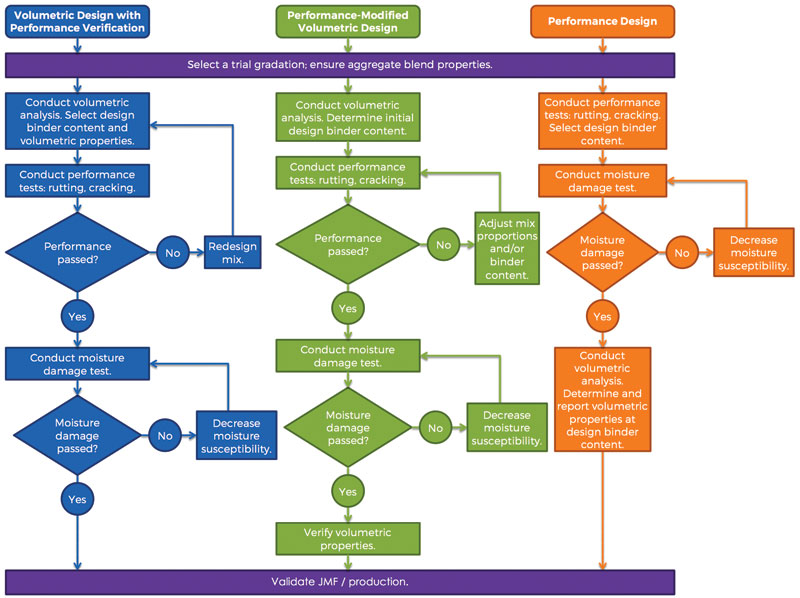

In September 2015, the FHWA Expert Task Group on Mixtures and Construction formed a Balanced Mix Design Task Force. This group defined balanced mix design (BMD) as “asphalt mix design using performance tests on appropriately conditioned specimens that address multiple modes of distress taking into consideration mix aging, traffic, climate and location within the pavement structure.” In short, BMD incorporates two or more mechanical tests such a rutting test and a cracking test to assess how well the mixture resists common forms of distress. The Task Force identified three potential approaches to the use of BMD: volumetric design with performance verification, performance-modified volumetric mix design, and performance design. These approaches are illustrated in Figure 1 and briefly discussed as follows:

- Volumetric Design with Performance Verification. Basically, this is the straight Superpave volumetric mix design approach with performance tests conducted at the end. If the mixture does not pass performance tests, the entire mix design process is repeated. This approach is currently used in Illinois, Louisiana, New Jersey, Texas, and Wisconsin.

- Performance-Modified Volumetric Mix Design. This approach begins with the Superpave mix design method to establish an initial aggregate blend and asphalt content. Adjustments in the mix proportions are then permitted to meet the performance tests. The final design may not be required to meet all of the traditional Superpave criteria. California currently uses this approach.

- Performance Design. This approach skips the volumetric mix design and starts with evaluation of mix trials (possibly multiple gradation trial blends and asphalt contents) using the performance tests. Minimum requirements may be set for asphalt binder and aggregate properties. Traditional volumetric criteria may be used as non-mandatory guides but not as design criteria. This approach is not currently used but could be a viable option.

Figure 1: Flowchart of Three Balanced Mix Design Approaches

Why Is Balanced Mix Design Needed?

Today, asphalt mixtures are primarily designed under the Superpave system, where proportioning of the aggregates and the asphalt binder relies primarily on empirical aggregate quality characteristics and mixture volumetric properties such as air voids, voids in the mineral aggregate (VMA), and voids filled with asphalt (VFA). Calculation of the volumetric properties is highly dependent on an accurate determination of the specific gravity of the mix components. However, there are well-known issues with the accuracy and variability of aggregate bulk specific gravity testing. This raises serious concerns about whether or not the correct amount of asphalt is selected in the mix design. Mixtures designed with too much asphalt may be susceptible to rutting, while those with too little asphalt are prone to cracking, raveling, and other durability related pavement distresses. Concerns about the accuracy of aggregate specific gravity determinations increase with the incorporation of reclaimed asphalt pavements (RAP) and recycled asphalt shingles (RAS). Moreover, the effects of the binders in these recycled materials are not captured in volumetric properties. It is still not well understood how recycled binders interact with virgin binders, which ultimately creates more doubt about how these materials affect field performance. Furthermore, the effects of warm-mix asphalt additives, polymers, rejuvenators, and fibers cannot be assessed in the current volumetric mix design method. Therefore, performance tests need to be included as part of the mix design procedure to help ensure desirable pavement performance in the field.

What Performance Tests Are Available, and How Are These Used in Balanced Mix Design?

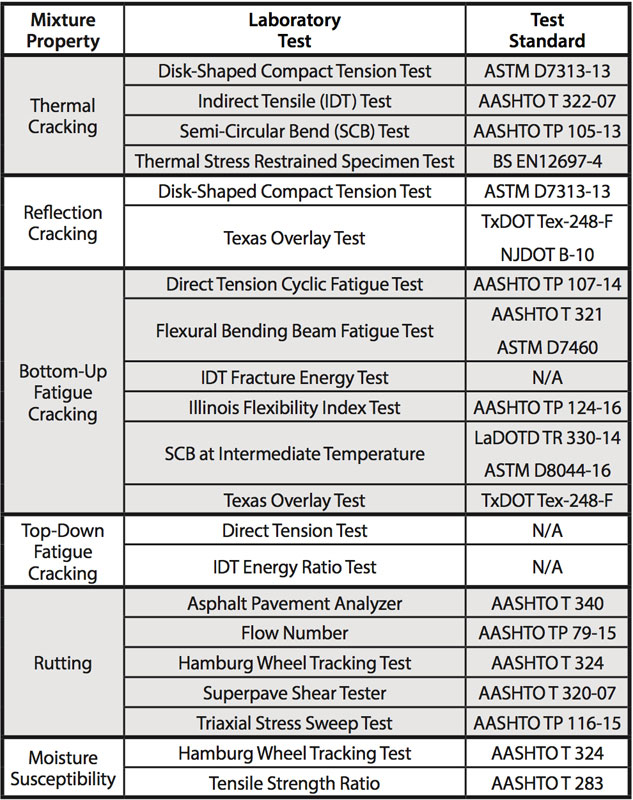

Over the past few decades, numerous performance tests have been developed by different researchers to evaluate the rutting resistance, cracking resistance, and moisture susceptibility of asphalt mixtures. Considering the different mechanisms in crack initiation and propagation, mixture cracking tests can be further categorized into thermal cracking, reflection cracking, bottom-up fatigue cracking, and top-down fatigue cracking. Table 1 provides a list of mixture performance tests that are commonly used in asphalt research and are being considered by highway agencies for use in mix design approval. In order to include any mixture performance test in the BMD procedure, criteria for the test result must be established based on a strong relationship to field performance.

Table 1: Commonly Used Asphalt Mixture Performance Tests

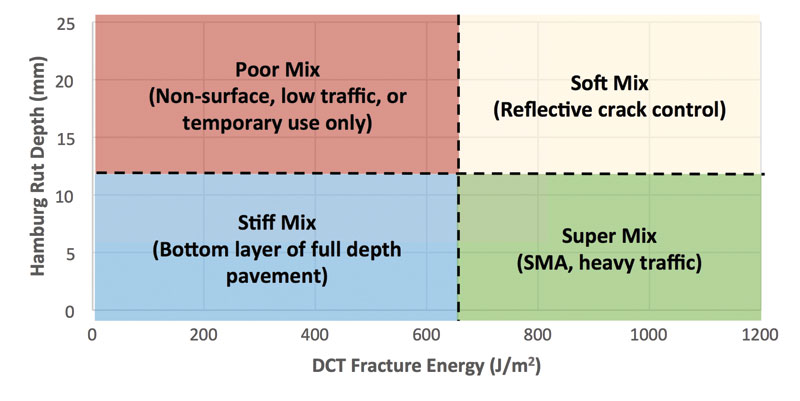

Performance space diagrams (PSDs) may be used in BMD to simultaneously chart the results of multiple performance tests. PSDs allow the mix designer to engineer the mix to provide the desired performance and to illustrate the impact of varying mix factors on performance. An example of PSD is shown in Figure 2. This example shows Hamburg wheel tracking test (HWTT) versus disk-shaped compact tension test (DCT) results and criteria to identify performance and applicability zones. Other test results such as stability versus durability/cracking can be substituted with the same application.

Figure 2: Example of Performance Space Diagram

What Is Being Done to Move toward Balanced Mix Design?

A few highway agencies have started to either explore or adopt approaches to BMD. Others are evaluating how their current mixtures fare with some of the performance tests. In Texas, where the BMD concept originated, the HWTT is used to evaluate resistance to rutting and the overlay test (OT) is used to evaluate cracking resistance. Volumetric criteria are used to select the asphalt binder content. Performance tests are conducted at three asphalt contents: optimum and optimum ±0.5%. The Louisiana Department of Transportation and Development uses a BMD approach that also uses the volumetric mix design process with the HWTT but uses the semi-circular bend (SCB) test and a parameter called J-integral to assess the cracking potential of mix designs. The Illinois approach is similar but uses a simpler SCB test that yields a parameter called Flexibility Index to assess cracking resistance.

The California Department of Transportation (Caltrans) has a pavement design framework that includes performance-based specifications and the CalME (Caltrans Mechanistic Empirical Design Program) to perform mix designs. Performance testing consists of repeated shear and frequency sweep tests using the Superpave shear tester, flexural bending beam fatigue tests, and HWTT.

Rutgers University recently proposed a performance-based balanced mix design procedure for the New Jersey Department of Transportation (NJDOT). The proposed method sets the asphalt content at the midpoint between the maximum asphalt content to meet the Asphalt Pavement Analyzer (APA) test criteria and the minimum asphalt content to satisfy the OT criteria. The performance criteria for both tests were established based on the field performance of existing NJDOT projects.

Minnesota, Ohio, Utah, Maryland, Wisconsin, and Florida are at various stages of research, development, and implementation of BMD. Despite all of these efforts, there are still some gaps in the knowledge needed for future development of a detailed, comprehensive standard practice. Some of the gaps include:

- - The relationship of test results to pavement performance,

- - Sensitivity of the test to changes in key properties (e.g. air voids),

- - Suitability of the tests to assess the effects of non-traditional materials,

- - Testing issues including precision, bias, and ruggedness,

- - Failure criteria for rutting and cracking tests appropriate for different regions,

- - Conditioning protocols for aging and moisture,

- - Tests for assessing workability, compactability, and segregation susceptibility,

- - Applicability of the tests to quality assurance and acceptance testing,

- - The role and use of volumetric properties,

- - The use of cores in the performance test, and

- - A lack of training materials and courses for implementation.

The most recent effort to move toward BMD is NCHRP Project 20-07/Task 406. The objective of this research is to develop a framework that addresses alternate approaches to devise and implement balanced mix design procedures incorporating performance testing and criteria. The project is expected to begin in spring 2017.

Also this spring, NCAT engineers began offering a Balanced Mix Design Course consisting of interactive lectures, demonstrations, and hands-on training with performance-based mix design procedures. This course is specifically designed to provide asphalt industry and agency personnel with a better understanding of the BMD concept based on results of laboratory tests that reflect how the mix will perform in regard to rutting resistance, resistance to cracking, and long-term durability.