Putting the Balance Back in Mix Design

Background

The original vision of the Superpave mix design system was to include three levels. Level I was envisioned for low traffic pavements and the mix design requirements would be primarily based on traditional volumetric properties. Level II would be used for projects that carry moderate travel levels and would include volumetric requirements plus a limited set of mixture performance tests. Level III would be for high traffic pavements and would start with volumetric based mix design followed by an expanded set of advanced performance tests. However, the proposed performance tests were never implemented, primarily because they were not practical for use in routine mix designs.

In the early years of Superpave implementation, the focus was on rutting resistance. Several changes in mix designs were proposed and were found successful in improving mixture resistance to rutting. A number of states also added a rutting test requirement for mixes designed for moderate and high traffic projects. Nowadays, most highway agencies report that rutting problems have been virtually eliminated, but many agencies have indicated that the primary form of distress for asphalt pavements is cracking of some form or another.

There are several possible contributing factors to increased cracking, including issues with the mix designs, increased use of recycled materials and byproducts, problems with the quality of construction, and failure to properly address underlying pavement distresses. Since it is now well recognized that the volumetric based mix design system has some shortcomings, many highway agencies and the asphalt paving industry are revisiting the possibility of using mixture performance tests in the mix design process to improve the life of asphalt pavements.

Balanced mix design (BMD) provides highway agencies with an alternative way to design asphalt mixtures by using performance tests to address multiple modes of distress while taking into consideration mix aging, traffic, climate, and location within the pavement structure. For BMD, asphalt mixtures are designed to achieve a balance between rutting resistance and cracking resistance using appropriately selected performance tests rather than relying solely on volumetric guidelines.

The FHWA Task Force on BMD has identified three potential approaches to the use of BMD: (1) volumetric design with performance verification, (2) performance-modified volumetric mix design, and (3) performance design.

State-of-the-Practice

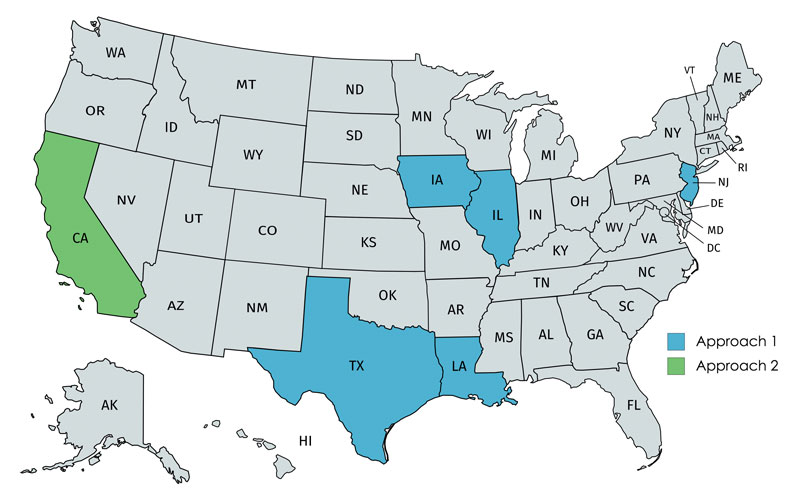

A few highway agencies have started to adopt approaches to BMD, and others are in the process of evaluating performance tests for integration into mix design requirements. Figure 1 highlights highway agencies identified by NCAT researchers as being focused on BMD. In addition, several other agencies currently require a performance test in their mix design specifications, but they are not using a “true” BMD approach according to the definition set forth by the FHWA Task Force to include at least one rutting test and one cracking test.

Figure 1: U.S. Map of Current Use of BMD Approaches

Currently, the most popular BMD approach among highway agencies is volumetric design with performance verification (Approach 1). States using this method include Illinois, Iowa, Louisiana, New Jersey, and Texas. This approach starts with the current Superpave mix design method for determining optimum asphalt binder content. Selected performance tests are then used to assess the mixture’s resistance to rutting, cracking, and moisture damage. If the mix design satisfies the performance requirements, the job mix formula (JMF) is established and production begins; otherwise, the mix design process is repeated using different materials or mix proportions until all performance criteria are met.

California is the only state using the second approach, performance-modified volumetric mix design. This approach begins with the Superpave mix design method to establish a design aggregate structure and preliminary binder content. Performance test results are then used to adjust either the binder content or component properties until the performance requirements are satisfied. The final design from this approach is primarily focused on passing performance test criteria and may not be required to meet all of the Superpave volumetric requirements.

No states have yet been identified for using the performance design approach, which would establish proportions of mixture components based on performance test results. Minimum requirements may be set for asphalt binder and aggregate properties. Air void and voids in mineral aggregates (VMA) might be non-mandatory suggestions. Once a mix satisfies the performance criteria, mixture volumetrics could be set for process control and/or simple and quick performance tests could be used to ensure quality during construction.

Additionally, several states have constructed or are preparing to construct pilot projects with BMD approaches by including performance testing and criteria. For example, Wisconsin constructed demonstration projects for mixtures containing more than 25% recycled materials in 2014. For these projects, the mix design target air void was lowered from 4.0% to 3.5% and the minimum tensile strength ratio (TSR) requirement was increased from 0.70 to 0.75. Performance tests including the Hamburg wheel-tracking test (HWTT), semi-circular bend (SCB-Jc) test, and disk-shaped compact tension (DCT) test were used to assess mixture resistance to rutting, moisture susceptibility, fatigue cracking, and low-temperature cracking. Oklahoma also plans to construct BMD trial projects in early 2018. It is anticipated that mix design and production samples will be tested with the HWTT, Illinois flexibility index (I-FIT) test, Cantabro, and TSR to ensure the designed mixtures have adequate resistance to rutting, cracking, and moisture susceptibility.

Knowledge Gaps for Implementation

Although many highway agencies have recognized the benefits of BMD approaches, there are gaps in the knowledge needed for future development of a detailed, comprehensive standard practice for BMD. In addition, there is an overall lack of understanding of the BMD concept among the asphalt paving industry. The three biggest questions that need to be addressed by future research on BMD are:

- For each mode of pavement distress, what are the best performance tests for BMD?

- What mixture conditioning/aging protocols should be used for selected performance tests?

- What are appropriate criteria for performance test results used in mix design and quality assurance?

Over the past few decades, numerous mixture performance tests have been developed to evaluate the rutting resistance, cracking resistance, and moisture susceptibility of asphalt mixtures. Considering the different mechanisms involved in crack initiation and propagation, mixture cracking tests can be further categorized into tests for thermal cracking, reflection cracking, bottom-up fatigue cracking, and top-down fatigue cracking. Some of these tests are better suited for routine use in mix design and quality assurance testing, while others are more focused on characterizing the fundamental properties of asphalt mixtures and predicting pavement response. In order to include these in the BMD procedure, criteria should first be established with good correlations to the corresponding pavement performance in the field. Considerations must also be given to practical issues such as testing time, data analysis complexity, test variability, equipment availability and cost, and sensitivity to mix design parameters.

Considering that asphalt aging plays a significant role on mixture performance, it is important to select an appropriate mixture conditioning/aging protocol for selected performance tests in BMD. There is a general consensus that rutting and moisture damage tests should be performed on short-term aged specimens because asphalt mixtures are more vulnerable to these two distresses right after construction. On the other hand, mixtures tend to be more susceptible to cracking after aging due to reduced flexibility; thus, long-term aged specimens should be used for mixture cracking tests. The standard short-term aging protocol specified in AASHTO R 30 is to condition loose mix for two hours at compaction temperature for mix design, but four hours at 135°C for performance testing. For long-term aging, AASHTO R 30 recommends aging compacted specimens for five days at 85°C. However, the long time span of this five-day protocol makes it difficult to implement in routine mix designs. Recently, alternative aging methods have been proposed to conduct long-term aging using loose mix prior to compaction. Loose-mix aging increases the rate of asphalt binder aging due to increased exposure to heat and oxygen to the thin asphalt coating. Some research has recommended loose mix aging at 95°C for five days, while other studies have recommended a higher temperature such as 135°C for much shorter time periods ranging from 12 to 24 hours.

NCAT’s Efforts on Balanced Mix Design

As a leading organization in asphalt pavement research, NCAT has identified BMD as a primary area of research. Currently, NCAT researchers are working on NCHRP Project 20-07/Task 406 Development of a Framework for Balanced Asphalt Mixture Design. The objective of this project is to develop a framework that addresses alternate approaches to devise and implement BMD procedures incorporating performance testing and criteria. Surveys of highway agencies and asphalt contractors were recently conducted to gather their experience, insights, and concerns with mixture performance testing and BMD approaches. Results will be presented in a webinar in fall 2017 through the Association of Asphalt Paving Technologists (www.asphalttechnology.org). Information collected through the survey and literature review will be used to develop research problem statements that address gaps in the knowledge required for future development and implementation of BMD.

Over the past five Test Track research cycles, NCAT has devoted significant research efforts on mixture design and performance testing of asphalt mixtures. The currently ongoing NCAT/MnROAD Cracking Group Experiment aims at validating mixture cracking tests by establishing correlations between laboratory test results and measured cracking in real pavements using real loading conditions. Upon completion of this experiment, industry-accepted laboratory cracking tests will be identified that can reliably relate to top-down and thermal cracking in asphalt pavements. The research findings will help highway agencies select the most suitable cracking tests for their BMD approach.

In spring 2017, NCAT engineers began offering a Balanced Mix Design Course consisting of lectures, discussions, and hands-on training with performance-based mix design procedures. This course is specifically designed to provide asphalt industry and agency personnel with a better understanding of the BMD concept based on results of laboratory tests that reflect how a mix performs in regard to rutting resistance, resistance to cracking, and long-term durability.