Civil and Environmental Engineering assistant professor receives grant to remove hazardous chemicals using electricity

Published: Apr 7, 2025 10:00 AM

By Dustin Duncan

Per- and poly-fluoroalkyl substances (PFAS) have been widely used across the world since the 1950s due to their exceptional resistance to heat, water, grease and stains. However, their widespread use has also led to environmental contamination, and according to the National Library of Medicine, 98% of the U.S. population has detectable concentrations of PFAS in their blood.

Dubbed the “forever chemicals” because of their longevity and resistance to disintegration — a characteristic resulting from their carbon-fluorine chemical bonds — PFAS can persist for thousands of years. They are found in cleaning products, food packaging, nonstick cookware, cosmetics, personal care items like dental floss, water-repellent clothing and stain-resistant carpets and upholstery. The U.S. military has also used firefighting foams containing PFAS to extinguish fuel-based fires in aircraft hangars, naval ships and training facilities.

Many companies worldwide have reduced the use of PFAS in manufacturing. However, because these chemicals have been widely used for more than 70 years and are difficult to destroy, they remain prevalent in many bodies of water.

Shiqiang (Nick) Zou, assistant professor in the Department of Civil and Environmental Engineering, believes he has a more efficient way to dispose of the PFAS-contaminated materials once water treatment plants collect them. He has received a $250,000 grant from the Department of Defense’s Strategic Environmental Research and Development Program (SERDP) to evaluate the effectiveness of his approach.

Currently, a common way to trap PFAS is by using granular activated carbon (GAC) – a material that acts as a sponge, soaking up PFAS from water.

However, once GAC is full, it becomes a solid hazardous waste that must be disposed of or cleaned.

Zou said the most common practice is to incinerate the GAC, which requires large amounts of energy, especially since the carbon contains water that must be evaporated before combustion.

But it’s not as simple as pouring gasoline on it and lighting a match. Zou said temperatures need to reach at least 1,000 degrees Celsius, though some facilities operate at even higher temperatures to fully break down PFAS.

“We’re not talking about normal burning,” Zou said. “We would need to get to really high temperatures.”

His solution? Hit it with a bolt of lightning.

“We want to develop a method that consumes less energy and is easier to manage,” Zou said. “Something that doesn’t produce large amounts of smoke, which people could potentially inhale when burning these hazardous chemicals.”

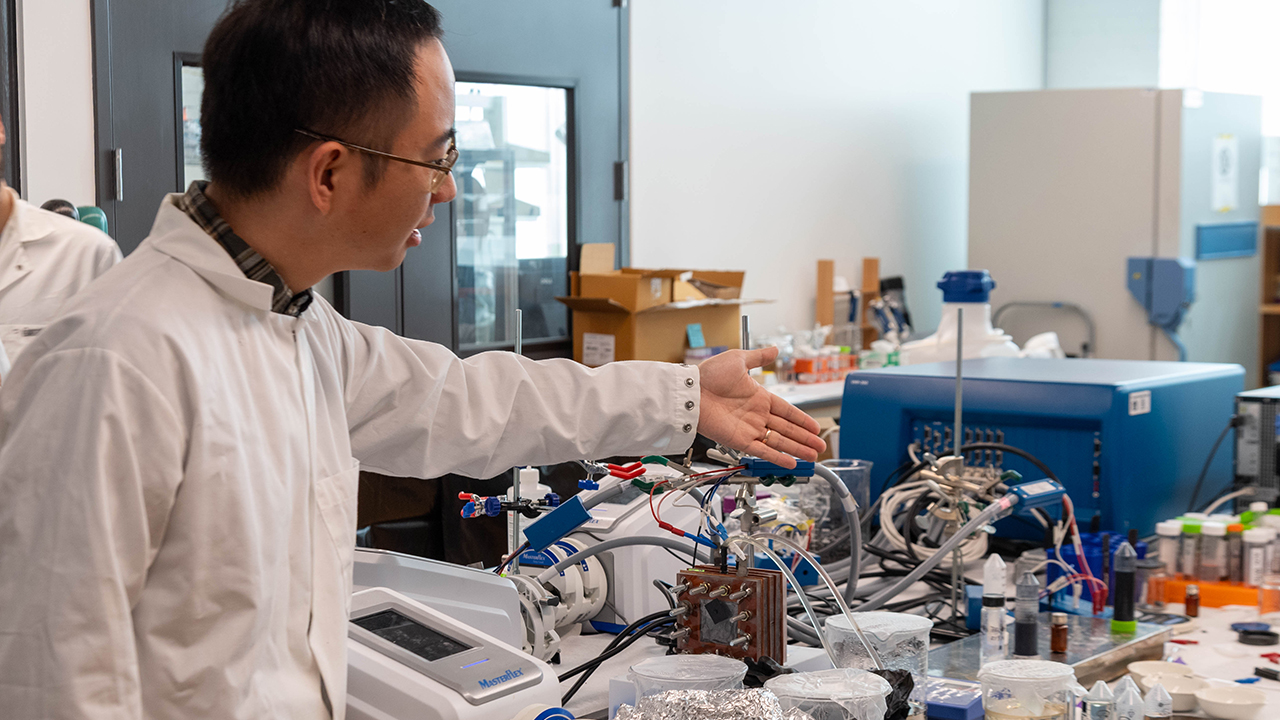

The approach is called electrochemical reduction, which uses electrical energy to break down PFAS while keeping the GAC intact for potential reuse. Zou said the process could be less expensive, more efficient and better for the environment than current methods

Zou’s team will receive actual GAC samples contaminated with PFAS while collaborating with The Water Tower, a water innovation hub in Buford, Georgia. After Zou zaps the carbon, he will send it to Dengjun Wang, assistant professor in contaminant fate and transport, at the University of Florida to evaluate the effectiveness of the technology. Wang previously was an assistant professor in the School of Fisheries, Aquaculture and Aquatic Sciences at Auburn.

The current project aims to determine whether Zou’s technology will work at a laboratory scale. He hopes this will lead to additional funding and larger-scale testing in real-world conditions.

“If this works, and we can demonstrate the efficiency and feasibility of the technology, hopefully, we can obtain additional funding to scale up testing and prove its broader use,” Zou said.

Media Contact: , dzd0065@auburn.edu, 334-844-2326

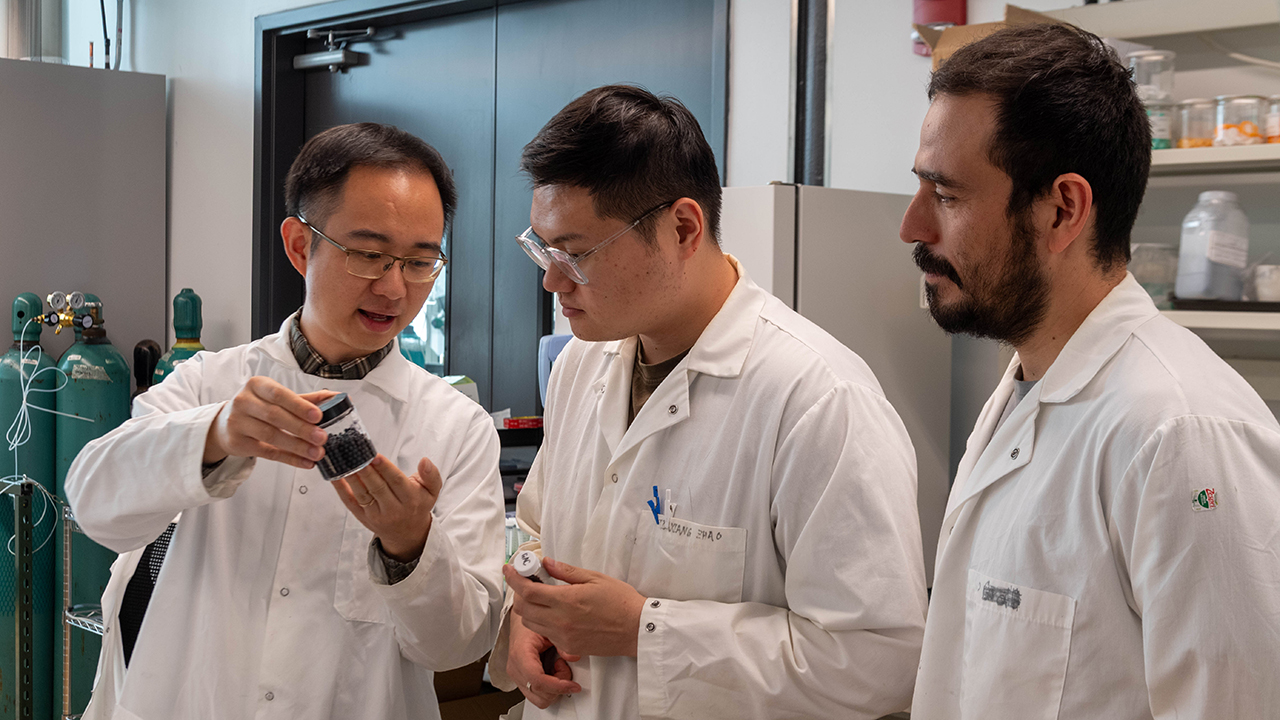

Shiqiang (Nick) Zou, assistant professor in civil and environmental engineering (center), holds a reactor used in electrochemical reduction, a process that uses electrical energy to break down per- and poly-fluoroalkyl substances (PFAS) while keeping granular activated carbon intact for potential reuse. Graduate assistant Jason Zhao (right) and postdoctoral fellow David Ricardo Martinez Vargas (left) are working with Zou on the project.