Center for Polymers and Advanced Composites a melting pot for collaborative, multi-disciplinary research

Published: Nov 13, 2023 8:25 AM

By Joe McAdory

Where can faculty and student researchers at Auburn University learn about and perform material characterization, collaborate on interdisciplinary research, like studying membranes for electrochemical applications, discovering how soil and moisture impacts agricultural planters, take a deep dive into the recycling of multi-layer plastics, and even develop and analyze materials for 3D printing?

The Center for Polymers and Advanced Composites (CPAC), of course.

CPAC, which serves as a melting pot for collaborative interdisciplinary research, fosters collaborations among multiple academic units across campus, including the Samuel Ginn College of Engineering, the College of Sciences and Mathematics (COSAM), College of Forestry, Wildlife and Environment, and the College of Agriculture.

“We bring people together from industry, academia and serve as a research hub,” said Bryan Beckingham, CPAC director since Jan. 1, who also serves as the Mary and John S. Sanders Associate Professor of Chemical Engineering. “CPAC is embodied in the word ‘center.’ A center is a place of community and engagement where research makes an impact.”

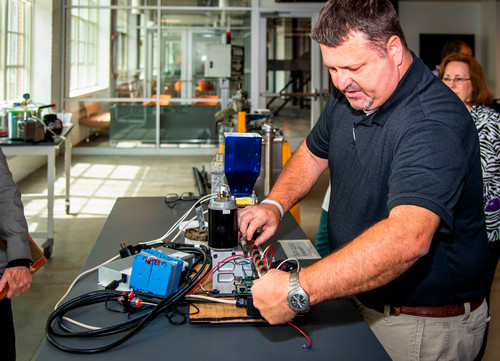

Launched in 2015 under the leadership of Maria Auad, associate dean for graduate studies and faculty development, CPAC offers researchers campus-wide 5,000-square feet of space in Gavin Laboratory, a plethora of equipment and expertise. The center offers specialized testing services in several areas, including chemical, mechanical, and thermal characterization. Through advanced polymer chemistry and testing laboratories, CPAC also innovates in materials processing and manufacturing research.

“We have a long list of polymer and material characterization equipment, including mechanical and chemical analyses as well as processing and fabrication equipment like polymer 3D printers, injection molding, melt pressing, and extrusion available to all university faculty,” Beckingham said. “We can process, fabricate, then test. If you’re doing work with materials, especially polymers and composites, we want to help. We offer expertise in material selection, material processing know-how, and selection and performance of characterization different characterization techniques.

“Critically, our lab manager, Dr. Ramsis Farag, is one of our best assets. He has lots of experience and loves working with students be it providing ideas and feedback for their materials or project, training and help using our equipment training, and generally facilitating the high-quality research that takes place in the laboratories.”

CPAC has been ISO/IEC 17025-accredited for materials characterization since 2022 and its new Service Center— which went online in April — is used by more than 34 faculty and student researchers representing multiple colleges.

“We have had students from pharmacy, agriculture, engineering, COSAM – all over the university – coming to use our facilities,” he said. “That’s why the service center was established and that’s why we’re constantly interested in expanding our capabilities. Our facilities include routine characterization such as thermal and mechanical testing (DSC, TGA, Instron, rheology, etc.) but also advanced 3D imaging using a Zeiss Xradia 620 Versa 3D X-ray CT nanotomagraphy (100 nm+ voxel size, samples up to 30 cm; In situ: heating, cooling, tensile, compression).

“CPAC is unique because we’re focused on polymers and advanced composites, but we are not specific to an application. Instead, we offer fundamental expertise and capabilities applicable to a variety of applications.”

Along with the service center, CPAC launched its 3D printing filament recycling program “ReMake,” in conjunction with the university’s Waste Reduction and Recycling Department, this past April.

The need: Many laboratories across campus utilizing additive manufacturing or 3D printing for various research and instructional purposes. The result? Plenty of waste material is left behind, leaving a substantial carbon footprint. What’s where ReMake comes in.

“Through ReMake, a student-led project, CPAC is helping breathe new life into this material that was previously being discarded,” Beckingham said. “The recycled material isn’t as high quality as new filament, but we are in the process of studying the mechanical properties of the recycled filament in comparison to new filament to identify the best uses for this product. So far this semester we’ve converted approximately 150 pounds of 3D printing waste into new filament for 3D printing.”

Beckingham is also pleased with the center’s newly created Research Amplification Program (RAMP), a mechanism for undergraduates, graduate students, post-doctoral students, and faculty to write short research proposals and describe how they would use the center’s testing facilities. Selected proposals are awarded laboratory time and expertise for 12 months.

“While many of our facilities are free to use, not all are. If approved, RAMP provides that student or faculty member with laboratory credit,” he said. “It’s a monetary grant to use our testing facilities, that do have costs associated with them, to get preliminary data for their respective projects. This helps provide faculty members with preliminary data for their grant proposal or students with data for their undergraduate research projects, or whatever the case may be. This is also a mechanism for new research collaborations that someone might not otherwise have facilities funding for.”

For more information about CPAC visit: https://www.eng.auburn.edu/research/centers/cpac/index.html.

Media Contact: , jem0040@auburn.edu, 334.844.3447

CPAC offers an array of research opportunities. Here, a self-folding polystyrene shape-memory polymer is placed beneath thermal energy from an infrared radiation lamp.