Chemical engineering professors create USDA, NSF-funded research that could positively impact global food supply, environment

Published: Aug 17, 2023 10:00 AM

By Joe McAdory

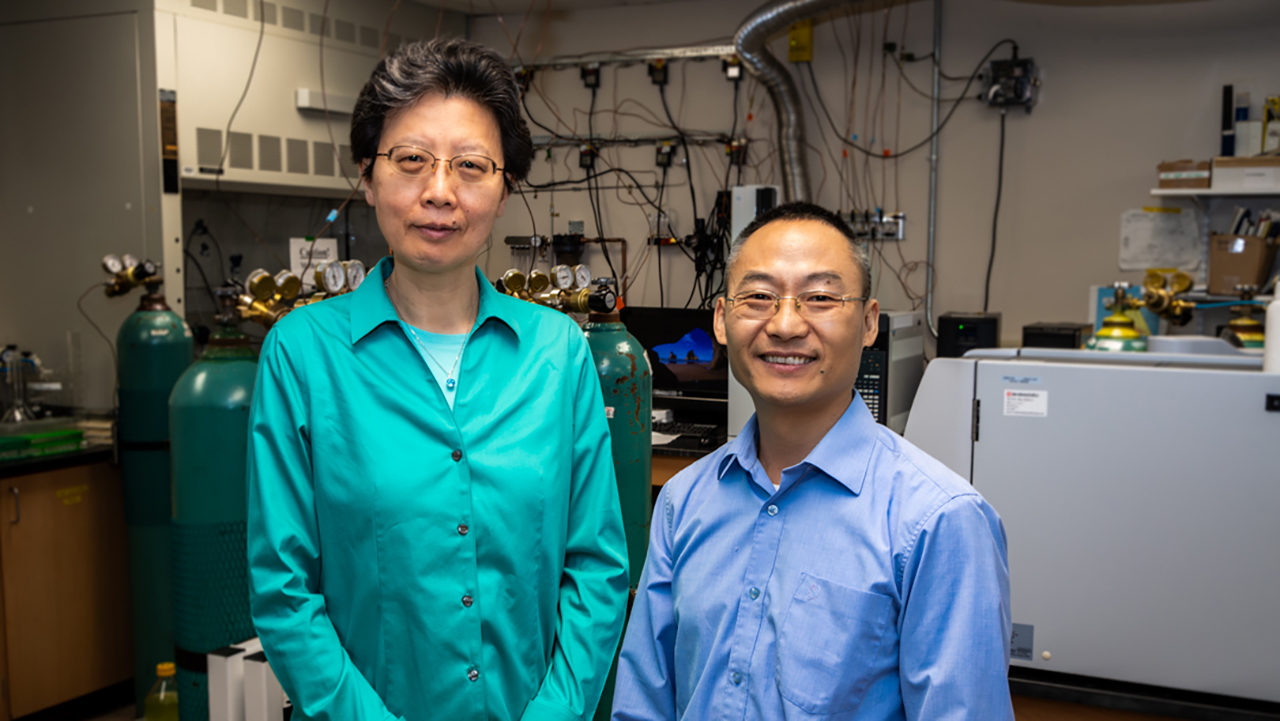

Two professors in the Department of Chemical Engineering are determined to create research that could not only positively impact the global food supply but also address global warming.

Jin Wang and Peter He co-authored a pair of studies that explore means to convert bio-gas into animal feed – creating a sustainable circular aquaculture industry – and remove methane from the atmosphere. Sounds remarkable? The U.S. Department of Agriculture (USDA) and National Science Foundation (NSF) believe so.

Their project, “Circular Aquaculture Through A Next-Generation Waste-to-Feed Biotechnology,” earned a four-year, $650,000 USDA grant, while a second study, “A Novel Multi-Tray Dry Biofilm Reactor for Methane Capture from Air,” was awarded a two-year, $200,000 grant from the NSF.

“We want to make a real impact to our society,” said Wang, the Walt and Virginia Woltosz Professor of chemical engineering, 2022 recipient of Auburn University’s Creative Research and Scholarship Award, and director of the Wang laboratory. “We don't just want to publish nice papers… we want to provide solutions that solve real problems.”

Responding to the rapidly increasing global population and demand for animal protein, aquaculture has become the fastest-growing animal food production sector. With competition for natural resources, among other production sectors, the intensification of aquaculture systems has emerged as a promising pathway for augmenting aquaculture production. This doesn’t come without challenges, however, and the USDA believes Auburn researchers can meet these challenges.

“On one hand, there is an increasing demand for aquaculture products and a shortage of certain aquafeed ingredients, such as proteins,” Wang said. “On the other hand, only about 30 percent of the nutrients supplied to farmed aquaculture animals are converted to product. The rest is excreted as soluble nutrients or settleable solids, which causes eutrophication when discharged into the environment. Our project proposes to produce aquafeed from aqua waste, which solves two problems with a single solution.”

He, associate professor and principal investigator of the He Group: Data-Enabled Process Systems Engineering (DE-PSE), led his team constructed a 68-liter lab-scale circulating coculture biofilm photobioreactor (CCBP) prototype to produce single-cell protein as a potential nutrient source. The device can be operated at any desired temperature, offers a significant reduction in greenhouse gas emissions through anaerobic digestion.

“Using the prototype, we have achieved an aerial coculture biomass productivity of 144.6 gDCW/m2/day, which is more than a four-fold increase from the highest reported microalgae productivity,” He said. “The CCBP will play a key role in this project as it delivers unprecedented performance in microbial cultivation.”

The plan:

- Aquaculture waste is broken down into biogas, nutrient-rich effluent, and biosolids in a controlled and contained manner.

- Single-cell proteins and treated water are produced from biogas and nutrient-rich anerobic digestion effluent within the CCBP

- Coculture is immobilized at a high concentration along a conveyor belt, which significantly increases the conversion.

The desired results: high-quality aquafeed supplements and fertilizers are derived.

Environmental benefits are one thing… but there’s more to the story. “Besides environmental benefits, this project will benefit the aquaculture industry economically,” said He. “By coupling aqua-waste management with aquafeed production, the project will not only increase waste management efficiency while reducing cost, but also produce a valuable product – fish meal valued at more than $1,000 per ton.”

The National Science Foundation study reveals an opportunity to reduce global warming via methane removal from the atmosphere. According to research, methane contributes approximately five-tenths of the observed 1.1 degrees Celsius present-day warming relative to the Earth’s pre-industrial global surface temperature.

This project will again utilize the multi-tray high-reaction-surface biofilm reactor to capture methane from the atmosphere and convert this gas into single-cell proteins. Wang acknowledges the collaboration and strong support from the world-renowned microbiologist, professor Mary Lidstrom from the University of Washington, who will provide the novel biocatalyst to be used in the biofilm reactor. Together with other technologies, the ultimate goal is to trim 300 million tons of methane by 2050 to have a real impact on the climate change – slowing global warming by 0.1-0.2 oC.

Locations where methane concentration is elevated – landfills, manure lagoons, or wastewater treatment plants – will serve as proving grounds where methane is captured from the air and converted to protein for animal feed.

“If successful, the project will demonstrate the first economically feasible technology to capture methane from air in areas with a local methane concentration of 500 to 5,000 parts per million, such as landfills, manure lagoons, or wastewater treatment plants, and converts it into a valuable product, single cell protein or SCP, for animal feed, further reducing the emission of greenhouse gas,” Wang said.

Media Contact: , jem0040@auburn.edu, 334.844.3447

Chemical engineering professors Jin Wang, left, and Peter He.