- 2023 Fall

Friction: Dynamics of Macro-Texture related to Friction

Pavement surface texture plays a significant role in maintaining safe roadways.

Increased texture typically yields safer pavements by providing larger channels, or “valleys”, for water to be displaced between the exposed surface aggregates as vehicles pass over. This reduces the overall film thickness of the sheet of water running off the pavement during rain events and exposes more aggregates to improve friction between the tires and pavement, especially at high speeds.

Gradation and type of asphalt mix directly affect the surface texture of the pavement. Gradation and mixture type are the two most effective options for targeting certain levels of texture. For example, coarser mixes will have taller “peaks” and deeper “valleys” due to the increased amount of coarse aggregate particles. Gradation and mixture type selection are the two most effective options for targeting certain levels of texture.

The Primary Control Sieve Index (PCSI) is a simple index to describe the overall fineness of a gradation. Specifically, the PCSI is defined as “the difference in percentage passing between the given gradation and the point on the maximum density line (MDL) at the primary control sieve (PCS)” (Leiva and West, 2021).

Fine mixes have positive PCSI values and coarse mixes have negative values. For 12.5 and 9.5 mm NMAS mixtures, the primary control sieve is the 2.36 mm (#8) sieve.

Although other methods of describing gradations with a single value exist, the PCSI describes gradation in a simple manner and has been used effectively to explain other asphalt mixture characteristics like surface texture, permeability, compactibility, and volumetrics.

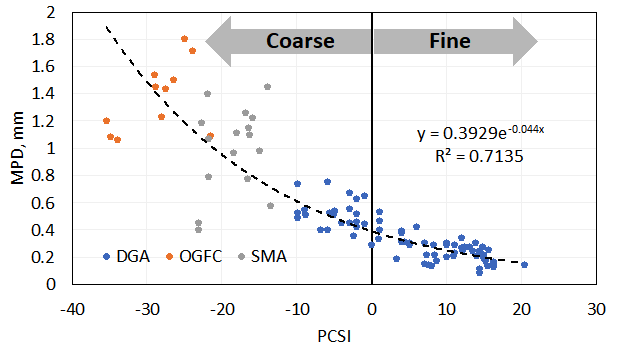

The relationship between the PCSI and as-built surface texture is demonstrated below in Figure 1.

The data shown represent the as-built mean profile depth (MPD) measured by the Automatic Road Analyzer (ARAN) van on the NCAT Test Track after construction of the 2000, 2003, 2006, and 2009 NCAT Test Tracks versus the PCSI calculated from Quality Control (QC) data during construction. The data from 2000 were taken one month after traffic began and the data from the other Track cycles were measured before traffic was applied.

The sections are divided into three mixture types: Dense-graded asphalt (DGA), Open-graded surface courses (OGFC), and Stone Matrix asphalt (SMA). Every section represented in Figure 1 is either a 9.5 mm NMAS or a 12.5 mm NMAS.

As expected, OGFC are the coarsest group of mixes, with PCSI values less than -20. This indicates that the percent passing the PCS for these OGFC mixes is at least 20% below the MDL.

Unsurprisingly, OGFC mixtures on the Track yield the highest texture. Every OGFC mix had MPD values after construction greater than 1.0 mm. SMA mixtures are not as coarse as OGFC mixes but are coarser than DGA mixes. The texture of the SMA mixes on the first four cycles of the Test Track varied from as low as 0.4 to as high as 1.4. SMA mixtures should typically have more texture than coarse dense-graded mixes.

Finally, the PCSI zone between -10 and 20 represents the DGA mixes. A clearer trend exists between texture and PCSI for DGA mixes. The probability of increased texture increases as mixes move coarser. Fine-graded 9.5 mm NMAS mixes represent a majority of the cluster of data between approximately 13 and 20 PCSI values. These sections also represent most of the sections with the lowest texture in the entire group.

The PCSI parameter adequately differentiates between mixture types and also correlates with texture very well. The The coefficient of determination (R²) of the best-fit, representing an exponential relationship between PCSI and texture indicates that 71% of the variability in texture in these surfaces is explained by the PCSI alone.

The main source of variability in this relationship is the OGFC and SMA mixes. These mixes are significantly coarser mixes which are more prone to segregate during construction than fine mixes.

Regardless, the relationship between PCSI and texture is clear.

Texture alone does not predict friction performance. Asphalt pavement friction relies on the microtexture of the aggregate particles to provide adequate skid resistance. However, texture plays a vital role in building and maintaining safe roadways and should not be ignored.

For mix designers, safety engineers, or pavement engineers, the PCSI provides a useful index to describe gradation and its effect on surface texture of asphalt pavements.

Contact Nathan Moore at nathan.moore@auburn.edu, for more information about this project.