Enhanced Compaction to Improve Durability and Extend Pavement Service Life

As stated by R. Bruce Noel at the 1977 annual meeting of the Association of Asphalt Paving Technologists (AAPT), “The single most important construction control that will provide for long-term serviceability is compaction.” When compaction is enhanced, in-place density can be optimized, thereby improving durability and extending pavement service life.

A review of several past studies clearly shows the effect of reduced air voids on improved fatigue and rutting performance of asphalt mixtures, both in the laboratory and field. Depending on mix type and experiment (which included constant-stress bending beam fatigue testing and field results from WesTrack), fatigue performance improved between 8.2 and 43.8% with a 1% decrease in air voids. Likewise, based on rutting results from WesTrack and laboratory flow number testing, rutting resistance improved by 7.3 to 66.3% with a 1% decrease in air voids depending on mix type and analysis. The results of a recent study conducted for the New Jersey Department of Transportation, which included data from 55 pavement sections, also suggest that a 1% decrease in in-place air voids increases asphalt mixture service life by conservatively 10%.

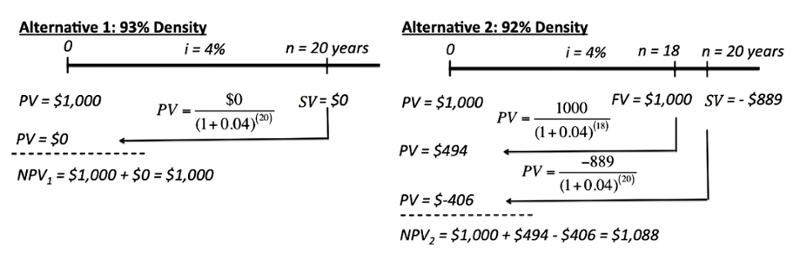

For illustration purposes, consider the effect of increasing the in-place density of an asphalt overlay from 92 to 93%. The service life will increase by conservatively 10%, meaning that the overlay will be expected to last 20 years instead of 18. Figure 1 shows a life cycle cost analysis (LCCA) of the two alternatives with an analysis period of 20 years.

Figure 1: Life Cycle Cost Analysis (per $1000)

For alternative 1, the initial construction cost of the overlay compacted to 93% density is assumed to be $1,000,000. The cost of providing a 1% increase in in-place density is assumed to be negligible, so the same initial cost is used for both alternatives. At year 20, the overlay in alternative 1 will be replaced, thus, the salvage value is 0 and the net present value (NPV) is $1,000,000. For alternative 2, in which the overlay is compacted to 92% density, the overlay will be replaced at year 18 at a future cost of $1,000,000. The new overlay (also expected to last 18 years) will have a remaining life of 16 years at the end of the 20-year analysis period and a prorated salvage value of $889,000. The replacement cost and salvage value is discounted to year 0 at a real discount rate of 4%, resulting in an NPV of $1,088,000 for alternative 2. Thus, on a $1,000,000 paving project, an NPV cost savings of $88,000 (or 8.8%) will be realized simply by increasing the in-place density requirement by 1%.

Because in-place density is such an important factor affecting long-term pavement performance, it is a key pay factor for acceptance in most states. The most common minimum in-place density criterion is 92 percent of theoretical maximum specific gravity (Gmm). Most density criteria are based on what could be achieved in the past and are not necessarily optimal in-place densities. Significant advances have been made in asphalt design and construction technology in recent years, making it possible to achieve greater densities.

Pneumatic tire rollers are used on the NCAT Test Track to achieve proper compaction and in-place density.

Since higher in-place densities can result in significant cost savings due to extended pavement service life, highway agencies may consider increasing minimum density requirements. Higher in-place densities can be achievable by following best practices and implementing new technologies and techniques. For guidance on best practices, a recently presented webinar entitled “Best Practices in Compaction” is available for download (free for NAPA members) at store.asphaltpavement.org.

Warm-mix asphalt (WMA) technologies, including asphalt foaming technologies and chemical and organic additives, can aid in compaction. WMA improves the workability of the asphalt binder and allows for mix production at temperatures 25 to 90°F lower than HMA. A review of several regionally diverse studies comparing the quality of WMA and HMA mixtures showed that similar in-place densities can be achieved with WMA at considerably lower compaction temperatures. Using WMA can result in improved in-place densities for projects with extended haul times as well as cold-weather projects.

Intelligent compaction (IC) is another technology that can help improve in-place densities. With the IC system, vibratory rollers are equipped with GPS-based mapping along with instrumentation that provides real-time monitoring of compaction and material stiffness. This allows adjustments to be made as needed to reach optimum density and uniform coverage while eliminating unnecessary roller passes and making the process more efficient. Optional feedback controls can also make continuous adjustments to the force and frequency of the roller drum. IC is a potentially useful tool for quality control, but it is not a replacement for acceptance testing, as the relationship between IC stiffness measurements and in-place density is inconsistent.

Many premature pavement failures are caused by low density at longitudinal joints. Well-constructed longitudinal joints require very close attention to detail during the paving and compaction process. During compaction of the first lane, the roller should overhang the unconfined edge by six inches. When placing the adjacent lane, there should be an overlap of one to one-and-a-half inches, and it is crucial that there is sufficient material (about 20% additional thickness) to allow for proper compaction. This lane should be compacted from the hot side with the roller drum extending six inches over the joint. In recent years, several other techniques have been used to improve longitudinal joints, including the use of a tapered or wedge joint, which also eases the vertical transition between lanes during construction. Also, two methods that may help bonding occur between the cold and hot edges of the joint are tack coat application on the joint and the use of infrared heaters to reheat the cold edge.

Minor increases in density are feasible and provide a cost-effective means of improving pavement service life. For increased density specifications to have maximum benefit and effectiveness, agencies should consider the following:

• Appropriate project selection. When choosing projects for implementing higher in-place density requirements, evaluate the underlying base. If the base is weak, optimal compaction will be difficult to achieve.

• Lift thickness. Increased lift thickness can improve compaction effectiveness because the mat cools more slowly, allowing more time for compaction. Also, lift thickness should be sufficient to allow for the re-orientation of aggregate particles during compaction. Fine-graded mixes should have a minimum lift thickness of three times the nominal maximum aggregate size (NMAS). For coarse-graded mixes, minimum lift thickness should be four times the NMAS.

• Mix design. Appropriate binder content should be selected for the desired in-place air voids. Gradation, binder content, and volumetric properties such as air voids and voids in mineral aggregate (VMA) can influence compactability of a mix and should be carefully controlled during production to minimize variability.

• Criteria. Appropriate measures of field compaction should be used for acceptance requirements. Comparing in-place density with theoretical maximum density allows less potential for variability in field compaction than comparison with density of laboratory samples.

• Performance incentives. As shown in the LCCA example, in-place density has a significant economic impact on highway agencies. Thus, performance incentives should be established to encourage enhanced compaction and achieving higher in-place density.

This literature review, which supports the FHWA Asphalt Pavement Technology Program strategic directive on extending pavement service life through enhanced compaction, will soon be available as an NCAT report.