Auburn vision for flexible electronics future aligns with major focus of CES 2025

Published: Jan 27, 2025 3:00 PM

By Jeremy Henderson

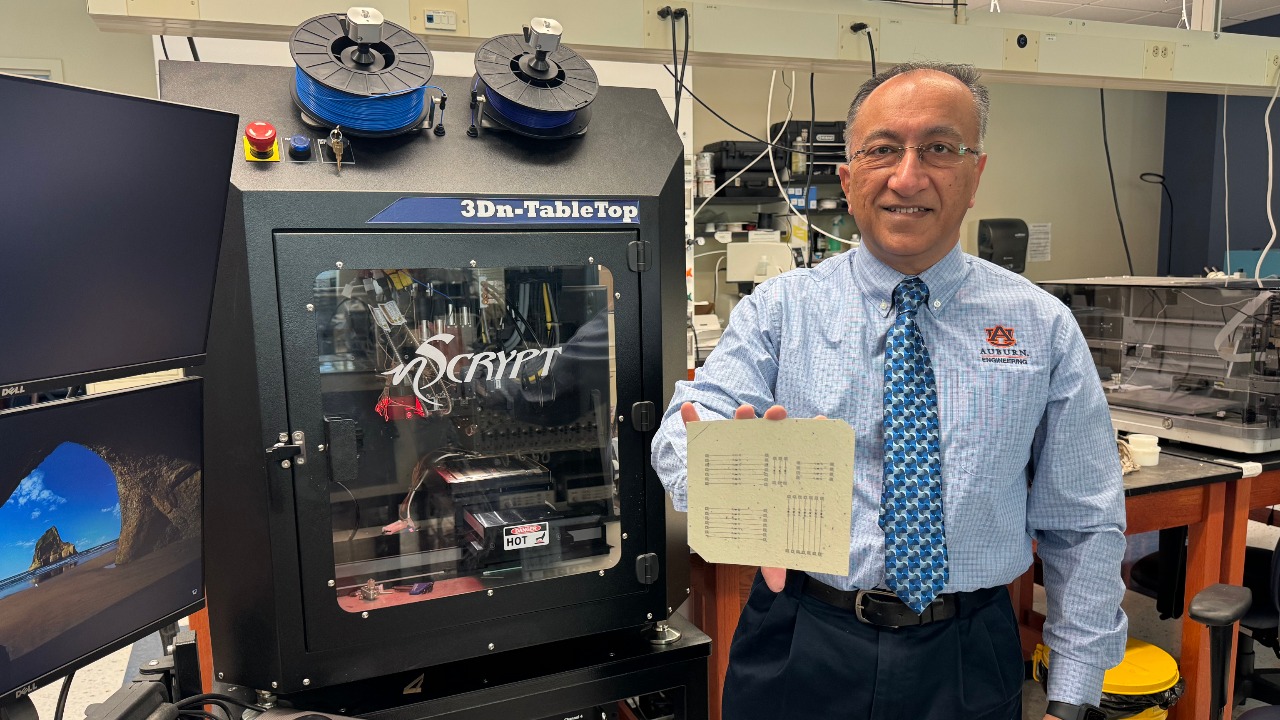

Auburn University's Electronics Packaging Research Institute (EPRI) was established this past summer. Judging by the reports of wide-eyed, gizmo-giddy tech journalists covering the annual Consumer Electronics Show (CES), the timing couldn't have been better.

AI dazzled. Robots wowed. But plenty of attention at the recent CES in Las Vegas was directed toward the flexible future of electronics demonstrated primarily in foldable (and even moldable) OLED screens, some of which can even bulge and flatten seamlessly, depending on the dynamics of what is displayed.

That's a future EPRI Director Pradeep Lall has been building for years.

While many of the eye-grabbing gadgets presented by companies like Samsung and LG were geared toward entertainment, Lall's research focuses primarily on the more practical application of flexible hybrid electronics, or FHE, in the automotive and aerospace industries.

FHE combines the adaptability of printed electronics and the high performance of traditional electronics, fitting together sensors and circuits printed on bendable materials with rigid silicon chips and batteries. This allows for the creation of electronic devices that are not only flexible and lightweight but also powerful and functional.

In 2015, Lall, an influential voice in electronics manufacturing and reliability, led the Auburn team contributing to the winning proposal that resulted in the foundation of the NextFlex National Manufacturing Institute. Auburn is a tier-1 founding member of NextFlex, whose mission is to advance U.S. manufacturing of flexible hybrid electronics, or FHE. Lall serves on the NextFlex technical council and co-leads two technical working groups focused on road mapping technology progression for automotive electronics, as well as asset monitoring.

In 2023, Lall received Semiconductor Equipment and Materials International’s (SEMI) FlexTech R&D Achievements Award in 2023. In 2024, he received the Surface Mount Technology Association (SMTA) Founder’s Award for exceptional contributions to the electronics manufacturing industry.

“The automotive sector is undergoing a paradigm shift toward more sustainable, connected and intelligent vehicles," Lall said. "Flexible electronics play a crucial role in this evolution, providing solutions that integrate seamlessly into the vehicle's design, improving both the user experience and the functionality of the car."

A promising — and increasingly sustainable — contributor to those solutions? Additively manufactured electronics, an area in which EPRI has a strong, established infrastructure, which now includes the capacity for printing circuits directly onto biodegradable paper substrates actually containing seeds.

"Many of the electronics concepts recently showcased in Las Vegas last focused on the potential of flexible hybrid electronics to achieve greater integration of form and function, as well as sustainability," Lall said. "This is an area in which additive printed electronics processes excel through enabling the realization of electronics on contoured non-planar surfaces. EPRI's work on the realization of FHE on automotive platforms really has its finger on the pulse of industry trends for future platforms."

At CES 2025, several automakers showcased seats integrated with flexible sensors capable of detecting the driver’s posture, heart rate and body temperature. This data can be used to automatically adjust seat position and temperature and even trigger health alerts.

“EPRI has recently demonstrated the development of steering wheel, door handle and center console integrated galvanic skin response sensors using in-mold electronics for the measurement of the state of driver parasympathetic nervous system including anxiety, anger and fear," Lall said. "Auburn University’s partnership with NextFlex National Manufacturing Institute has been instrumental in maturing some of these nascent technologies.”

To see those same technologies highlighted at CES "is very exciting," Lall said. "Especially since the maturation of additive processes for the realization of printed FHE in a number of these challenging high-volume automotive applications is happening right here at EPRI."

Media Contact: , jdh0123@auburn.edu, 334-844-3591

Research at the Electronics Packaging Research Institute (EPRI) includes aerosol-jet additive processing for manufacturing flexible electronics.