ICAMS receives $9.2M to further Model-Based Systems Engineering

Published: Mar 13, 2024 1:00 PM

By Dustin Duncan

The Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS) has once again answered the call from the Department of Defense (DOD).

The $9.2 million DOD project, "Manufacturing Model-Based Systems Engineering," calls for ICAMS to address the need for more adoption of enhanced digital capabilities in the defense industry. ICAMS will train current and future employees in Manufacturing Model-Based Systems Engineering (M-MBSE) capabilities to maintain workforce competitiveness. Additionally, ICAMS will develop and prototype M-MBSE capabilities with small- and medium-sized manufacturers (SMMs).

There's been an increased request for MBSE approaches, modeling languages, and tools in the development and execution of manufacturing systems, which has given rise to a new field called M-MBSE.

M-MBSE is the intersection of manufacturing and MBSE principles, according to Gregory Purdy, co-principal investigator on the grant and assistant professor in the Department of Industrial and Systems Engineering (ISE).

"Essentially, we are trying to figure out at what point in the life cycle of a manufactured part MBSE tools and approaches overlap," Purdy said. "Based on these overlap areas, we need to develop capabilities and training to support the evolving skillset of workers in this space."

ICAMS will provide cybersecurity training for operational technology to SMMs, deliver MBSE training and identify the essential skill set for success in an M-MBSE workplace.

"Through our work in ICAMS, we've identified that these are really focus areas that need to be developed within the workforce," Purdy said.

Additionally, ICAMS wants to help existing employees in the manufacturing industry continue to learn new skills and knowledge.

"Also, we want to bring new people into manufacturing who already have the skills necessary to succeed, be on the cutting edge of technology and solve problems in terms of securing operational technology," Purdy said.

ICAMS will be doing more than training for the defense industry — it will also create several prototypes.

Need help streamlining daily tasks such as scheduling, quoting and tracking several data points? ICAMS can help by developing software designed for SMMs. Purdy said such software exists in the open market but is usually cost-prohibitive for many SMMs.

Other prototypes from this project include helping companies reduce large amounts of manual data entry and helping analyze that data to improve current operations and build for a more profitable future. Also, ICAMS will develop and prototype model-based metrology capabilities that include scanning and coordinate measuring machine systems for model development and sharing.

Lastly, ICAMS will dive headfirst into the world of distributed manufacturing, which is a way of organizing production, so it's spread out across different locations. This allows manufacturing parts to be closer to where they are needed, reducing lead times and company transportation costs. ICAMS will develop these capabilities for SMMs between two or more facilities. The ICAMS Auburn University Research and Innovation Campus in Huntsville and the ICAMS facility in Auburn will be connected as testing sites for development.

Purdy said ICAMS will build the digital storage infrastructure prioritizing data security and integrity.

"These are all projects that fall under ICAMS's umbrella to try to help the defense industrial base," Purdy said.

Greg Harris, director of ICAMS and ISE chair, said M-MBSE focuses on the idea of convergence of technologies that will strengthen the defense industrial base.

“The tasks in this program will provide direct benefit to the SMMs who make the parts and are the backbone of the defense industrial base by providing tools and capabilities for digitalizing their operations, training and upskilling the existing workforce and educating the next generation of engineers and scientists,” Harris said.

Established in 2018, ICAMS offers the equipment, space and expertise to demonstrate, train and educate students and industry personnel in advanced manufacturing technologies. ICAMS' efforts focus on reducing the barriers inhibiting the introduction of advanced manufacturing technology systems in small and medium manufacturing operations.

Media Contact: , dzd0065@auburn.edu, 334-844-2326

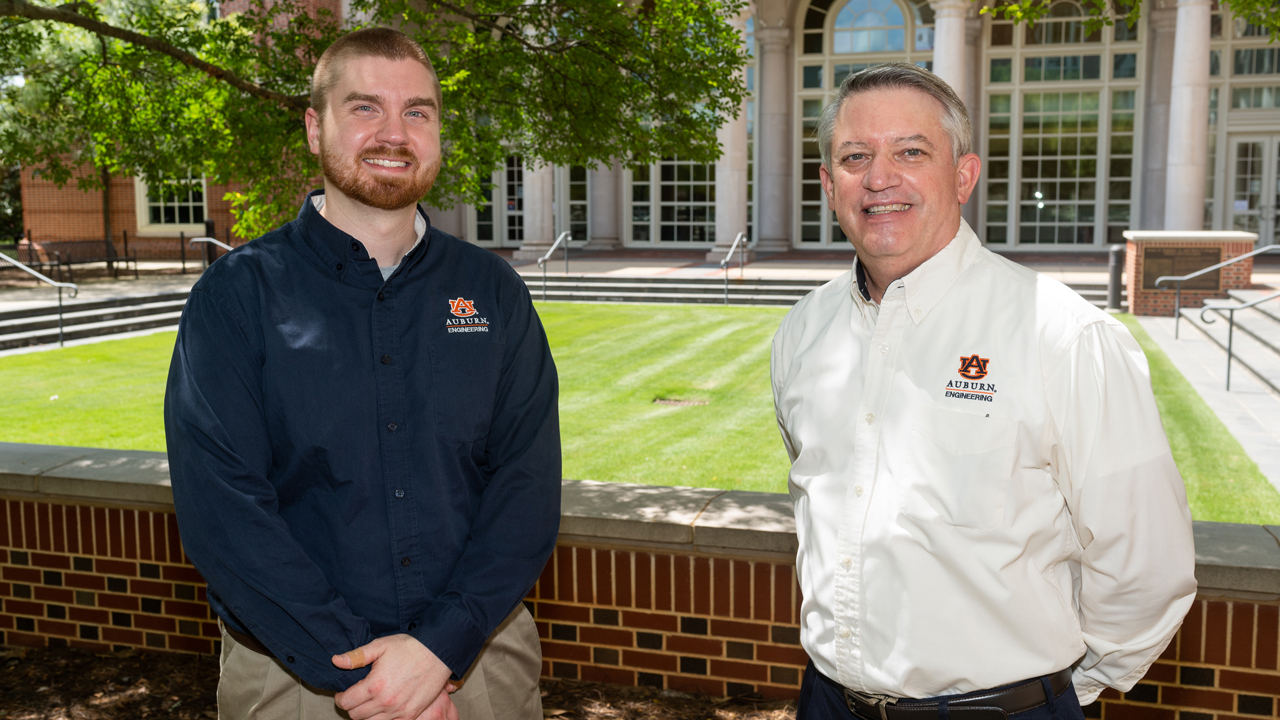

Gregory Purdy, assistant professor in the Department of Industrial and Systems Engineering stands next to Gregory Harris, director of ICAMS and ISE chair, for a photo on Auburn University’s campus.