NIST awards Auburn nearly $1M to lead NDE-based AM qualification via data analytics

Published: Aug 10, 2022 10:00 AM

By Jeremy Henderson

The National Institute of Standards and Technology (NIST) recently awarded Auburn University's National Center for Additive Manufacturing Excellence (NCAME) and the ASTM Additive Manufacturing Center of Excellence (AM CoE) nearly $1 million to establish through computer vision and machine learning a data-driven framework for the non-destructive qualification of additively manufactured materials and parts for mission critical applications.

The framework will allow for the rapid identification of critical defects and the prediction of fatigue performance with non-destructive evaluation (NDE) data.

"Additive manufacturing (AM) has gained significant attention from key industrial sectors including aerospace, defense, automotive, and medical due to its unique capability of fabricating customized parts with complex geometries on demand," said NCAME director Nima Shamsaei, Philpott-WestPoint Stevens Distinguished Professor of mechanical engineering. "However, current AM platforms are still prone to producing parts with varying degrees of defects detrimental to the parts’ structural integrity, specifically in fatigue critical applications."

NDE-based and prediction-based qualifications are key to expedited adoption of AM, said Shuai Shao, associate mechanical engineering professor.

"Conventional qualification approaches are challenging when directly applied to AM due to the parts' defect content being sensitive to many process parameters," Shao said.

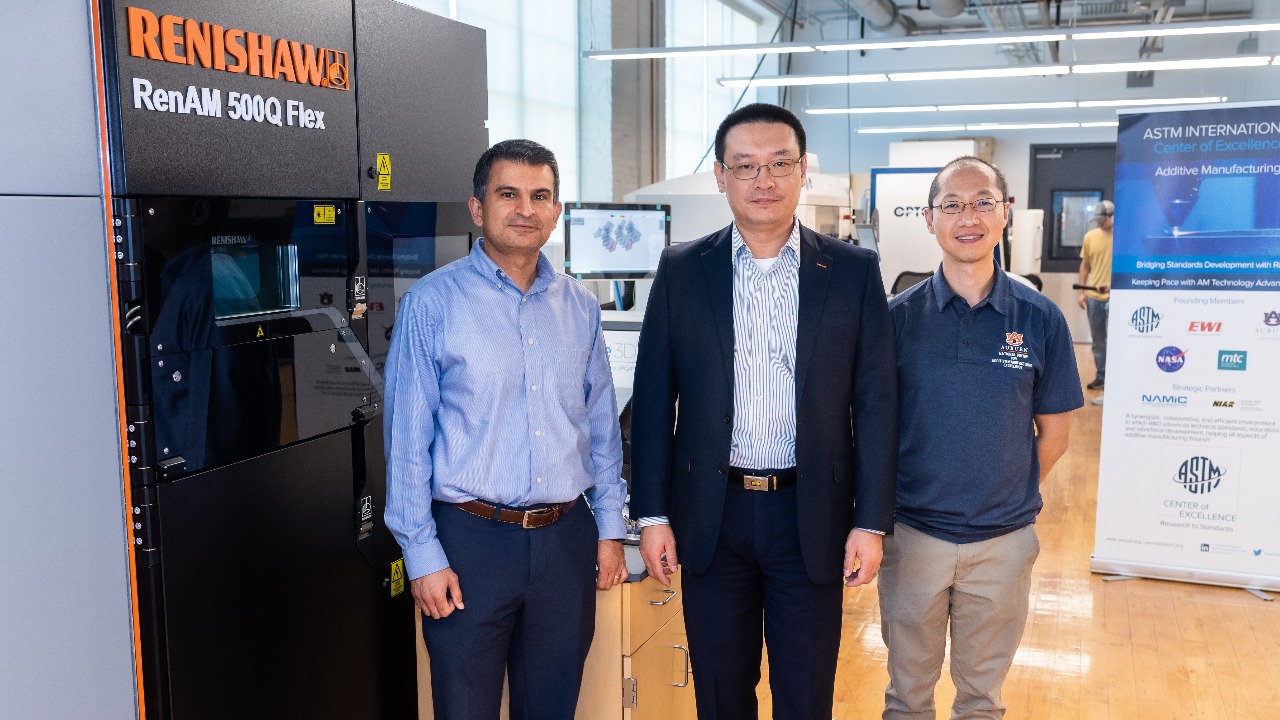

Shamsaei is the project's principal investigator (PI). Co-PIs from Auburn are Shao and assistant industrial and systems professor Peter Liu; Co-PIs from ASTM International are Mohsen Seifi, Mahdi Jamshidinia and Aaron McCandless .

"Extracting defect features with computer vision and correlating them with fatigue performance using machine learning, are the main ingredient of the proposed NDE-based qualification framework." Liu said.

Established in 2017 through a public-private partnership between Auburn and NASA, NCAME has built one of the world's most robust environments for framework-based analysis of fatigue performance towards qualification and certification of additively manufactured materials and parts. For example, NCAME has been conducting research for the Federal Aviation Administration (FAA) on matters affecting the AM qualification and certification, specifically in fatigue-critical applications.

This most recent award reflects NIST's continuing efforts to address barriers to AM adoption through measurement science supporting equivalence-based qualification and model-based qualification, the characterization of materials, and standards to support consistent data exchange and characterize new advances in AM production systems.

Over the course of the two-year project, NCAME and ASTM AM CoE researchers will also work with NIST scientists to explore ways to incorporate their findings into data management systems like NIST’s Additive Manufacturing Materials Database (AMMD) as well as potential pathways for standardization needs.

"Research need in this area is extremely timely and important," said Seifi, ASTM International’s vice president of Global Advanced Manufacturing.

Formed in 2018, the ASTM AM CoE aims to accelerate the development and adoption of AM by supporting standardization, developing training and certification programs, and providing market intelligence, business strategy and advisory services.

"The goal of this NIST funded project is well-aligned with the mission of the newly established AM CoE Consortium for Materials Data and Standardization (CMDS) with members representing the entire AM value chain," Seifi said.

Media Contact: , jdh0123@auburn.edu, 334-844-3591

Nima Shamsaei, Shuai Shao and Peter Liu