Aerospace engineering doctoral student works to advance rotating detonation rocket engines

Published: Mar 24, 2025 2:20 PM

By Dustin Duncan

An aerospace engineering doctoral student is focused on improving wave dynamics in rotating detonation rocket engines (RDREs), a compact and high-efficiency propulsion system that could reduce the size, weight and cost of future launch vehicles in space.

Ari Goldman works in the Combustion Physics Lab under the guidance of David Scarbrough, associate professor in the Department of Aerospace Engineering.

Goldman said that RDREs differ from traditional rocket engines by using detonation instead of constant-pressure combustion, allowing for a combustion chamber that is 50% to 70% smaller while maintaining comparable thrust. The engine’s ring-shaped design drives detonation waves at 4,000 to 6,000 feet per second, enhancing combustion efficiency. As a result, the engine delivers excellent performance while enabling a significantly shorter design.

“A traditional rocket engine is often twice the length of an RDRE,” Goldman said. “In spaceflight, where every pound matters, cutting engine length in half is a major advantage.”

Another benefit of the RDRE is its potential for higher specific impulse at the same average chamber pressure. Goldman said that engineers at NASA’s Marshall Space Flight Center and Glenn Research Center are evaluating this capability.

Goldman’s research focuses on wave dynamics — how fast the detonation waves move, how many exist simultaneously and how effectively they burn. Unlike a single traveling wave, RDREs can have multiple waves moving through the engine simultaneously. His work quantifies and controls this behavior based on various design parameters.

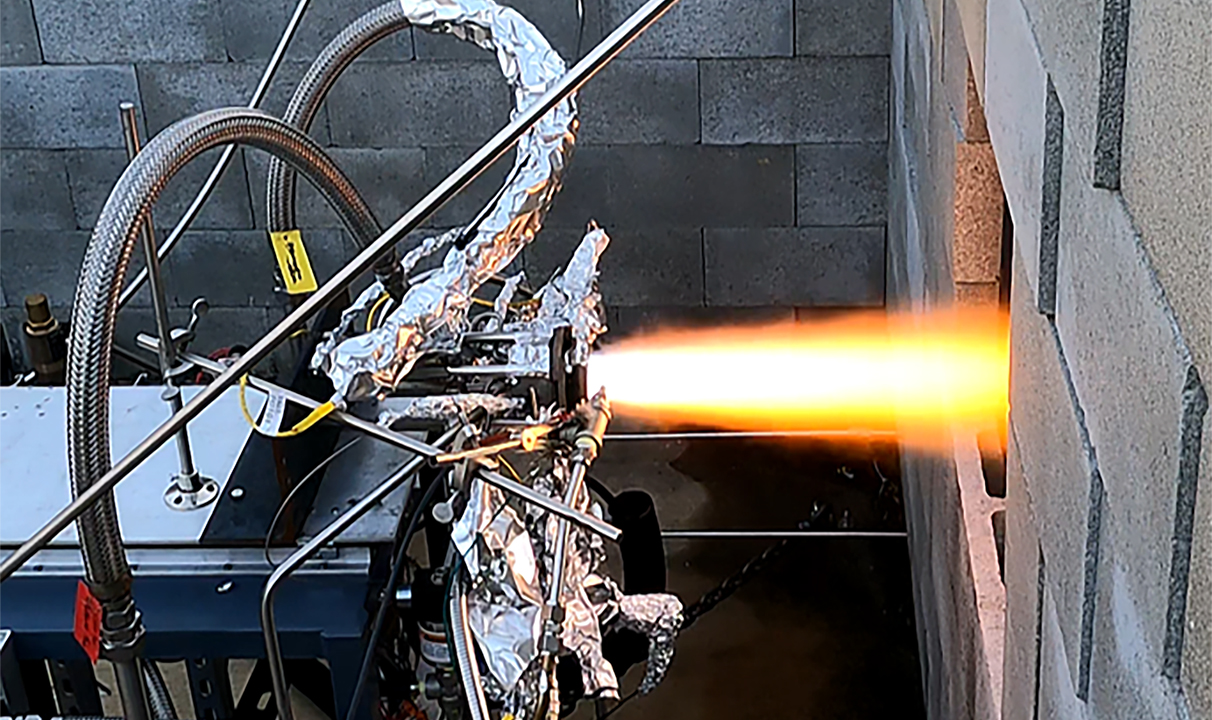

A key element of this research is the MARLEN engine, the third generation of subscale RDREs. Goldman helped design the manifold and injector system, which manages fluid flow before combustion in the engine’s annulus — the region between the engine’s inner and outer bodies. The MARLEN engine has been fired more than 100 times and set a record for the highest chamber pressure of any RDRE — nearly double the previous benchmark.

"This has been an incredible program to be a part of," Goldman said. "It’s been amazing to contribute to the design, study the problem, collaborate with experts at Marshall, and bring that knowledge back to Auburn."

The RDRE currently under testing produces 700 pounds of thrust, providing valuable insights for future developments. The goal is to scale this technology for larger launch vehicles.

One of the key enablers of this research is additive manufacturing, specifically 3D metal printing, using a process called laser powder bed fusion. In this method, a laser selectively melts metal powder layer by layer to create complex engine components.

This cutting-edge approach allows for rapid design iterations at relatively low costs.

Goldman and his team have conducted small-scale experiments to assess how design adjustments impact engine performance. One major challenge is managing the extreme heat generated during RDRE operation, which reaches local heating comparable to the Space Shuttle Main Engine within a two-inch-diameter subscale engine.

"We've been able to run small-scale experiments where we tweak individual parameters and observe how the engine responds," Goldman said. "It's given us valuable data while keeping costs and turnaround time manageable."

Beyond his work on the RDRE, Goldman reflected on Auburn’s growth in developing the infrastructure to test rockets.

"Three years ago, Auburn didn’t have a test cell for rocket engines," he said. "There was no facility to run these kinds of experiments. We had to build everything from the ground up."

He recalls being there when the concrete for the test pad was first poured. Since then, the team has made significant progress, creating a full-fledged research facility capable of supporting cutting-edge propulsion studies. In fact, Auburn had its first successful RDRE test on campus on Dec. 18.

It’s been quite something to see how far we’ve come," he said.

Media Contact: , dzd0065@auburn.edu, 334-844-2326

Ari Goldman, aerospace engineering doctoral student (left) and David Scarbrough, associate professor in the Department of Aerospace Engineering (right) stand in front of the MARLEN engine, the third generation of subscale RDREs.