________________________________________________________________

The Laboratory for Fatigue & Additive Manufacturing Excellence (FAME) is a state-of-the-art research facility at Auburn University. The research team has privileged access for utilizing the specific equipment listed below. In addition to the below equipment, FAME personnel can use a fully-equipped machine shop with: CNC, lathes, end mills, drill presses and more.

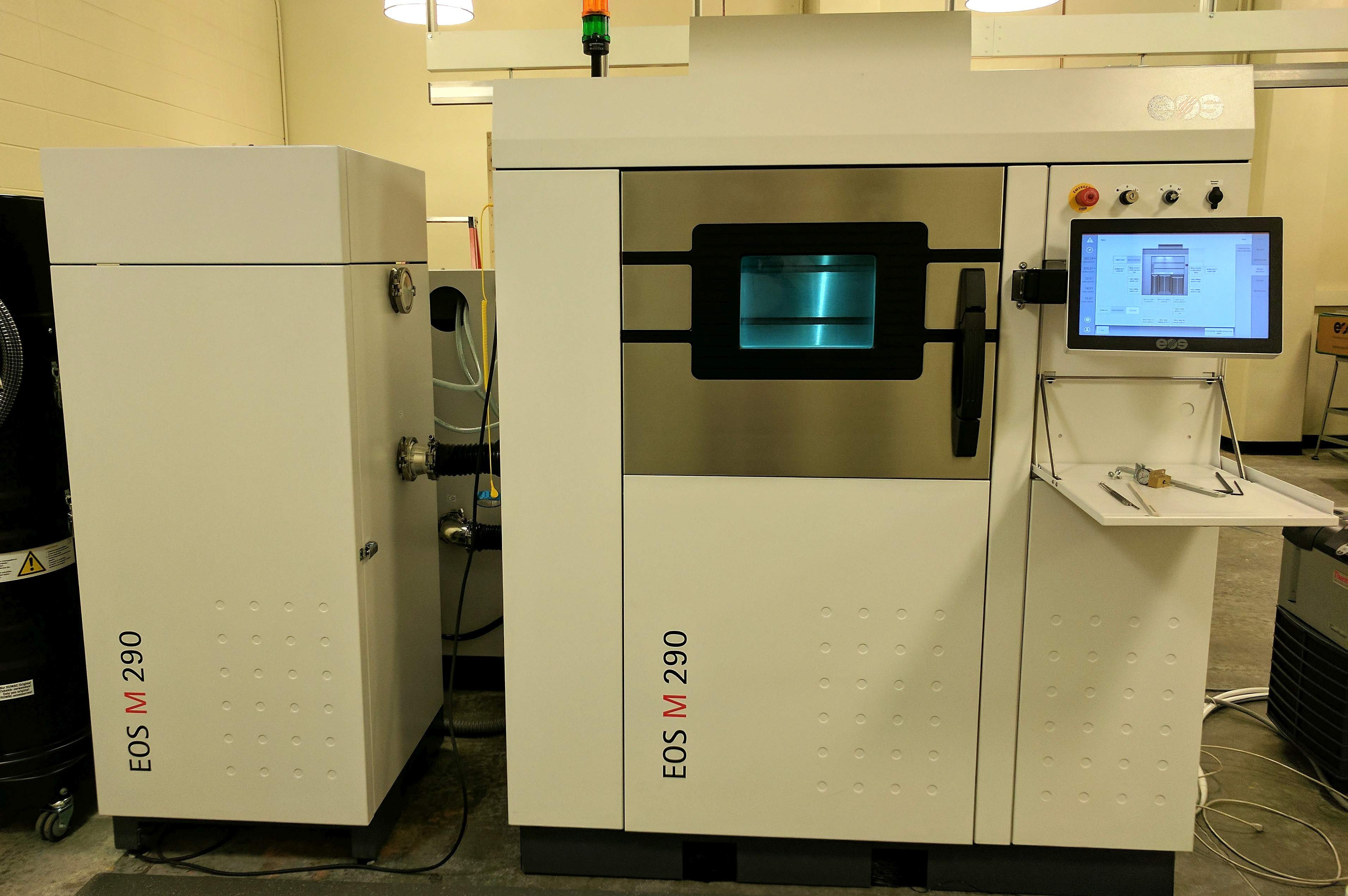

EOS M290 w/ 400 W Laser

The EOS M290 is a Direct Metal Laser Sintering (DMLS) system used for the additive manufacture. A focused laser beam is used to selectively melt regions of a powder bed. DMLS is advantageous for the fabrication of parts with internal cavities or overhanging structures, since the powder bed acts as a supporting structure during the build.

Key Features: 400 W laser power (Nd:YAG), integrated mechanical sieving station, dual mode operation (argon or nitrogen), integrated nitrogen generator, self-cleaning recirculating filter system (RFS), wet separator. FAME EOS M290 has the ParameterEditor bundle and experience in manufacturing: Inconel 718, stainless steel (SS) 17-4 PH, SS 316L, Ti-6Al-4V (titanium alloy), and AlSi10Mg (aluminum alloy).

x3 MTS Landmark 370.10 Uniaxial Tension/Fatigue Machines

MTS Landmark 370.02 Axial/Torsion (Multi-Axial) Fatigue Machine

Series 505 SilentFlo™ Hydraulic Power Unit