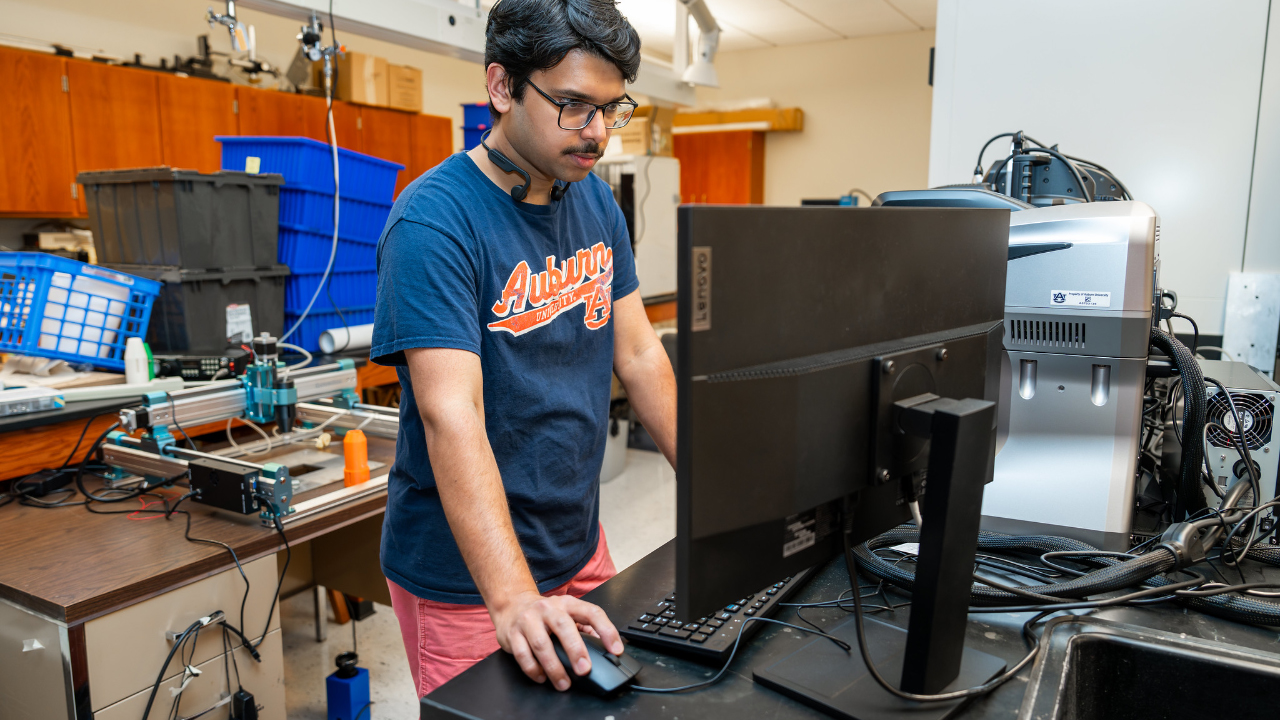

Electronics Packaging Research Institute (AUEPRI)

About the Center

Established in 1999, the Auburn University Electronics Packaging Institute (AUEPRI) develops and implements new technologies for the packaging and manufacturing of electronics.

Special emphasis is placed on the harsh-environment and reliability requirements of electronics in automotive and defense applications, including systems required to operate at sustained high or low temperatures, extreme temperature cycling, high acceleration, and in the presence of contaminants.

Driven by AUEPRI board members representing the materials, components, equipment, and electronic assembly industries, the institute’s research focus includes semiconductor packaging, additive manufacturing, electronics and chip packaging, electronics assembly, and reliability and prognostic health management.

With more than 30 member companies represented on the institute’s advisory board, AUEPRI continues to identify challenges and opportunities for new materials, processes, and approaches to electronics manufacturing, setting the standard among peer institutions.

The center is committed to cultivating long-term, extramurally funded research and educational relationships, serving as a hub for collaboration with academia, industry, national laboratories, and government entities. Together, we can build a more secure digital world.

-

AUEPRI regularly leads project calls and technology innovations in additive manufacturing electronics for the NextFlex National Manufacturing Institute for Flexible Hybrid Electronics.

-

Auburn University is a Tier-1 founding member of NextFlex.

-

Formerly known as the National Science Foundation Center for Advanced Vehicle and Extreme Environment Electronics (CAVE3).

-

Laboratory space inside Wiggins Hall includes a wide range of research and testing equipment for chip fabrication and characterization, additively printed flexible hybrid electronics, modeling and simulation, material characterization, surface-mount assembly, non-destructive analysis, packaging prototype lines, accelerated testing, and high-G survivability.